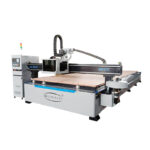

ATC Wood Furniture CNC Router Machine

CNC Router Furniture

CNC router furniture is a machine that uses computer-controlled movements to cut, shape, and engrave various materials, including wood, plastic, and metal. When it comes to furniture production, CNC routers are widely used in the manufacturing process.

The automation provided by the CNC technology also increases efficiency and productivity, as it can perform repetitive tasks quickly and consistently.

Description

CNC routers can accurately cut out furniture components from sheets of material, such as plywood or MDF (medium-density fiberboard). They can create intricate shapes, curves, and chamfers as per the design specifications.

CNC routers can create precise joinery, such as mortise and tenon joints, dovetail joints, and box joints. This ensures strong and accurate connections between furniture components, improving the overall quality and durability of the furniture.

CNC routers equipped with appropriate tools can engrave decorative patterns, logos, or text onto furniture surfaces. They can also perform intricate carvings and add personalized details to enhance the aesthetic appeal of the furniture.

CNC Router Furniture are often used in the prototyping phase of furniture design, allowing designers and manufacturers to test and refine their concepts before full-scale production. They also enable customization by easily adapting designs to meet specific customer requirements.

ATC Wood CNC Machine Features:

- Versatility: cnc router wood furniture can handle a variety of tasks such as cutting, carving, drilling, and milling. This versatility is crucial in furniture making, where different operations are needed for different pieces.

- Efficiency: With automatic tool changing capabilities, these routers can switch between tools without manual intervention. This significantly reduces production time and increases efficiency.

- Complex Designs: atc wood furniture cnc router can execute intricate designs with precision. This is particularly beneficial for furniture pieces that require complex detailing or artistic elements.

- Consistency: CNC routers ensure consistency in production. Each piece produced is identical to the design specifications, maintaining quality standards across the furniture line.

- Material Options: These routers can work with various materials used in furniture making, including wood, MDF (Medium-Density Fiberboard), plywood, plastics, and even metals. This allows for greater flexibility in design and material selection.

- Customization: atc wood furniture cnc router enable customization in furniture manufacturing. Design changes can be easily implemented without significant retooling, making it ideal for producing custom or bespoke furniture pieces.

- Cost-Effective: While the initial investment in CNC machinery can be high, the automation and efficiency they offer can lead to cost savings in the long run, especially for large-scale furniture production.

Hot applications include:

Production and processing of various types of furniture: cabinets, wardrobes, office furniture, computer tables, children’ s furniture, panel furniture, cutting and cutting, slotting and perforating, decoration hollow frames, soft bag background wall production, etc.;

Wooden door and furniture decoration industry: solid wood and composite door, cabinet door, large-area plate carving, solid wood, panel furniture carving, solid wood art mural carving, etc.;

Wood products processing: clocks, electrical countertops, sporting goods and equipment;>Musical instrument industry: three-dimensional curved surface and shape cutting of sculptable musical instruments;

Crafts industry: photo frames, jewellery boxes.

Furniture Production Line

Woodworking industry

Wooden Door Processing

Furniture Making

Wooden Furniture Processing

Cabinet Door Processing

Wooden Crafts Relief

Acrylic Cutting

Customized furniture, wardrobes, cabinets, kitchen cabinets, panel furniture, cabinet doors, cabinets, game cabinets, cloakroom cabinets, wine cabinets, office furniture, melamine board furniture cabinets, wood-based panel furniture cabinets, particle board furniture cabinets, plywood cabinet furniture, solid wood Plug-in panel furniture, bookcases, storage cabinets, chest of drawers, living room furniture, bedroom furniture, children’s furniture, study furniture, dining tables, dining chairs, coffee tables, Nordic furniture, modern furniture, blockboard furniture, MDF cabinets, oak boards Furniture, disassembly and assembly furniture.

FAQ

Making high-quality furniture no longer requires countless hours and dozens of different tools to create a beautiful masterpiece. Thanks to the evolving technologies of CNC routers, furniture making can be done in a fraction of the time, with one tool that comes with all the necessary attachments you’ll need to create that custom one-of-a-kind piece or bulk orders of similar works.

What Types of Furniture Can You Create?

The opportunities are genuinely endless when it comes to CNC furniture making. Depending on your machine’s size, the programming you have, and the available accessories, it’s possible to create unique designs and logos on surfaces and/or create one-of-a-kind pieces for select clientele.

Your opportunities are only limited by your creativity, the availability of necessary attachments, and the overall size of your CNC router machine. Here are only a handful of possibilities for CNC router furniture making:

- Bar Stools

- Bed Frames

- Bookshelves

- Cabinetry

- Children’s Chairs

- Coffee Tables

- Desks/Study Tables

- Dining Chairs

- Dining Tables

- End Tables

- Entertainment Centers

- Lap Desks

- Light Fixtures

- Peg Boards for Decorative Purposes

- Rocking Chairs

- Statement Artwork

- Storage Units

- Wine Racks

- Wooden Toolboxes

Depending on the programming and attachments you have available, you can create stunning designs in your pieces to make them genuinely unique for each individual you create for.

IGOLDENCNC offers clients the best in automated manufacturing solutions, which also come with lifetime technical support and the industry’s best product warranty.

Our CNC routers can move simultaneously on symmetrical planes using multiple heads and automatic tool changers. You can also equip them with routing, boring, grooving, planing, and sanding tools.

With the popularity of whole-house custom furniture, the panel furniture industry has also ushered in an unprecedented peak demand period. Many people who are engaged in furniture-related industries also want to open a panel furniture factory. However, opening a panel furniture factory is not simple. You need to consider many factors, such as factory buildings, environmental protection, furniture CNC machine, and labor. The following will focus on what furniture CNC machine is needed to open a small panel furniture factory.

To make cabinet body

To make only cabinet body, you may need the CNC cutting machine, edge banding machine, side drilling machine, etc. In addition, you may also need auxiliary machines, like the air compressor, hinge boring machine, etc. Generally, an economical panel production line with a CNC nesting machine and a side drilling machine could cost around USD35,000. But the price will go higher if you use high-end furniture making machines, such as the six-sided drilling machine.

To make only cabinet doors or room doors

If you make cabinet doors or room doors, you need major CNC machines such as the nesting CNC machining center, wood sanding machine, and vacuum press machine. In addition, the hinge boring machine and door lock hole making machine may be also required to make various connection holes. Generally, the price of an economical production line for cabinet door making is about USD30,000. But the price of more high-end production lines is higher.

To produce both cabinet body and doors

All the above-mentioned cabinet CNC machines are needed to make cabinet body and doors. That means you need the nesting machine, edge bander, CNC drilling machine, wood sanding machine, vacuum press machine, and other supplementary furniture making machines. The whole furniture production line may cost you about USD60,000. Of course, we have both economical and high-end production solution lines to meet the requirements of small and big furniture makers.

iGOLDENCNC, Your best choice

Becoming a customer of iGOLDENCNC, we will cooperate with you on the basis of complete trust and comfort. You will find that we are a reputable supplier and worth your trust. We understand that every customer is valuable, and we will cherish every opportunity to cooperate!

Strict Quality Control System

Advanced testing equipment are used, such as: dynamic balance tester, CNC high precision machining machine, 3D measuring machine; iGOLDENCNC has established a complete and strict quality control system, including 48-hour running test and 72-hour aging test, to ensure the excellent quality of our machines.