Redefining Glass Fabrication with CNC Glass Cutting Machines

CNC (Computer Numerical Control) glass cutting machines are transforming the way glass is processed in various industries. These advanced machines offer precision, efficiency, and versatility, making them indispensable tools for manufacturers, fabricators, and artisans alike. This article explores the features, benefits, applications, and future of CNC glass cutting machines.

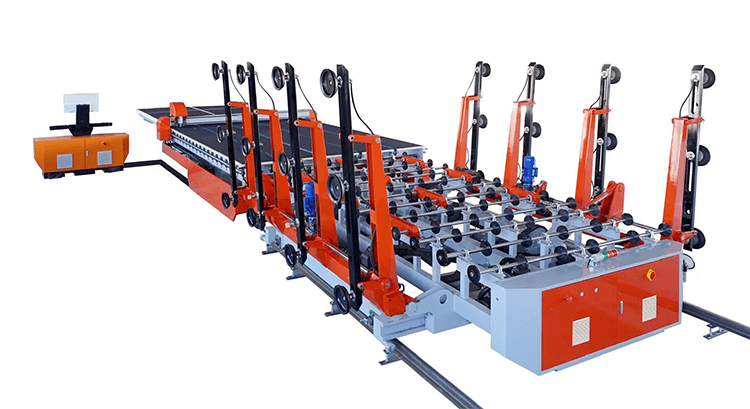

CNC Glass Cutting Machines

A CNC glass cutting machine is a computer-controlled device designed to cut glass sheets with high accuracy. By utilizing various cutting techniques, including straight cuts, curves, and intricate shapes, these machines streamline the glass fabrication process. They operate based on digital designs, allowing for complex patterns that would be challenging to achieve manually.

These advanced systems utilize computer-controlled cutting tools and automated features to perform intricate, customized cutting tasks with exceptional precision and efficiency.

Key Features of CNC Glass Cutting Machines:

1. Precision Cutting

CNC glass cutting machines can achieve tolerances as tight as ±0.1 mm. This precision ensures that each piece of glass fits perfectly, reducing waste and the need for rework.

2. Automation

Once programmed, CNC machines can operate autonomously, significantly reducing labor costs. Operators can focus on monitoring the process rather than performing repetitive tasks.

3. Versatile Cutting Options

These machines support various cutting methods, including:

- Straight Cuts: Ideal for standard glass sheets.

- Curved Cuts: Allows for artistic designs and custom shapes.

- Etching and Engraving: Adds decorative elements to glass surfaces.

4. Software Integration

CNC glass cutting machines often come with user-friendly software that enables operators to create and modify designs easily. CAD (Computer-Aided Design) compatibility allows for seamless integration with design programs.

Benefits of CNC Glass Cutting Machines

1. Increased Efficiency

Automating the cutting process significantly speeds up production times. CNC machines can operate continuously, allowing businesses to meet high demand without sacrificing quality.

2. Reduced Waste

With precise cutting capabilities, these machines minimize material waste. Accurate cuts mean fewer leftover scraps, translating to cost savings and a more sustainable production process.

3. Enhanced Safety

CNC machines reduce the risk of workplace injuries associated with manual glass cutting. Operators can maintain a safe distance from the cutting area, and advanced safety features protect users from accidental harm.

4. Customization

The ability to easily modify designs means businesses can offer a wide range of customized products. Whether it’s unique glass panels for architecture or personalized gifts, CNC machines provide the flexibility needed to meet diverse customer demands.

Applications of CNC Glass Cutting Machines

1. Architectural Glass

CNC machines are widely used in the construction industry for cutting glass panels used in facades, windows, and skylights. Their precision ensures that each piece fits perfectly within the overall structure.

2. Automotive Industry

In the automotive sector, CNC glass cutting machines manufacture windshields and windows with precise dimensions, contributing to vehicle safety and aesthetics.

3. Furniture Design

Glass is a popular material in modern furniture. CNC machines enable designers to create elegant glass tabletops, shelves, and decorative accents with intricate shapes.

4. Art and Decor

Artists and craftsmen use CNC glass cutting machines to create custom artwork, sculptures, and decorative panels. The ability to etch and engrave designs adds a personal touch to each piece.

The Future of CNC Glass Cutting Machines

As technology continues to evolve, the future of CNC glass cutting machines looks promising. Here are a few trends to watch:

1. Smart Technology

Integration with IoT (Internet of Things) allows for real-time monitoring and diagnostics, improving efficiency and reducing downtime.

2. Advanced Materials

New cutting tools and techniques are being developed to work with emerging glass materials, expanding the possibilities for design and application.

3. Sustainability

As industries move towards greener practices, CNC glass cutting machines will play a crucial role in minimizing waste and energy consumption.

4. User-Friendly Interfaces

Future machines will likely feature more intuitive interfaces, making them accessible to operators with varying skill levels.

In conclusion, CNC glass cutting machines stand as a beacon of innovation and craftsmanship in the world of glass fabrication, offering artisans and manufacturers the tools to push boundaries, explore creativity, and create exquisite glass creations that enchant and inspire. With their precision cutting capabilities, automated operation, versatility, and customization options, these machines pave the way for a new era of excellence in glass craftsmanship.

Whether you are a glass artist seeking to bring your designs to life or a manufacturer looking to optimize your glass fabrication processes, the adoption of a CNC glass cutting machine promises to elevate your craft to new heights of precision and beauty. Embrace the future of glass cutting technology and unlock a world of endless possibilities in the art of glass fabrication.

Conclusion

CNC glass cutting machines are revolutionizing the glass industry by offering precision, efficiency, and customization. Their applications span various sectors, from architecture to art, making them an essential tool for modern glass fabrication. As technology advances, these machines will continue to evolve, paving the way for innovative designs and sustainable practices in glass processing. Investing in a CNC glass machine may be one of the best decisions for any business looking to enhance productivity and stay competitive in the ever-evolving market.

Leave a Reply

You must be logged in to post a comment.