CNC and Laser Cutter: A Practical Guide to CNC Machining and Laser Cutting

In modern fabrication, two versatile approaches stand out: computer-controlled (CNC) machining and laser cutting. Whether you’re a hobbyist maker, a small workshop, or a full-scale production facility, understanding how CNC machines and laser cutters work—and where they complement each other—helps you select the right tool for the job. This guide breaks down the basics, compares the technologies, outlines practical use cases, and offers practical tips for choosing, implementing, and sourcing CNC and laser cutting solutions.

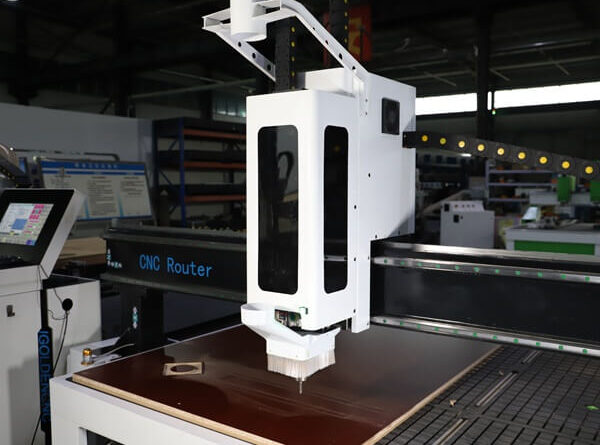

What Is a CNC Machine?

- Definition: CNC stands for computer numerical control. A CNC machine uses programmed instructions to move cutting tools (drills, end mills, routers) along multiple axes to remove material and shape a workpiece.

- Common configurations: 3-axis, 4-axis, and 5-axis milling machines; CNC lathes/turning centers; and CNC routers.

- Typical materials: Metals (aluminum, steel), plastics, composites, wood, and more, depending on the machine type and tooling.

- Core benefits:

- High precision and repeatability

- Ability to produce complex geometries with tight tolerances

- Automation-ready workflows for high throughput

- Scalability from prototyping to production

How They Work

CNC machines use rotating cutting tools (bits, end mills, drills) that physically remove material through contact cutting. They can work in multiple axes and create complex 3D geometries by moving the cutting tool through programmed paths.

Material Capabilities

CNC routers handle wood, plastics, soft metals (aluminum, brass), composites, and foam materials effectively. They can work with thick materials and create complex 3D shapes, pockets, and holes.

What Is a Laser Cutter?

- Definition: A laser cutter uses a focused laser beam to cut, engrave, or mark materials by ablation, melting, or vaporization. It can be a CO2, fiber, or other laser type, depending on the material and application.

- Common configurations: Desktop CO2 cutters, mid-sized sheet-cutting systems, and large-format laser cutters; some systems include multiple heads or scanning heads.

- Typical materials: Wood, acrylic, plastics, leather, textiles, some metals (with specialized setups), glass, and laminates.

- Core benefits:

- Very clean edges and high detail

- Minimal mechanical contact (low tool wear)

- Excellent for sheet materials, signage, branding, and prototyping

- Complex geometry and engraving capabilities

How They Work

Laser cutters use a focused laser beam to melt, burn, or vaporize material. The laser beam is directed by mirrors and lenses, creating precise cuts without physical tool contact. Most are limited to 2D cutting and engraving, though some can create beveled edges.

Material Capabilities

Laser cutters excel with thin materials like acrylic, wood (up to about 1 inch), paper, cardboard, fabric, leather, and thin metals (steel, stainless steel, aluminum). They struggle with reflective metals, PVC (releases toxic gases), and very thick materials.

Key Differences Between CNC and Laser Cutting

- Material interaction:

- CNC machining removes material with solid cutting tools, creating edges by shearing.

- Laser cutting removes material with a laser, creating edges through heat and material removal.

- Step geometry:

- CNC excels with 3D surfaces, pockets, threads, and deep pockets in metals and plastics.

- Lasers excel with intricate 2D patterns, fine detail, engraving, and controlled kerf on sheet materials.

- Tolerances and edge quality:

- CNC can achieve excellent tolerances on a wide range of thicknesses, especially with rigid setups.

- Laser cuts often show clean edges on thin to medium-thickness materials; edge quality depends on material type and laser wavelength.

- Throughput and material cost:

- CNC may be faster for deep pockets or high-material-removal tasks but can require more tooling and setup time.

- Lasers shine on thin sheets and low-to-medium volume runs with minimal tooling changes.

- Safety and maintenance:

- CNC milling involves cutting tools, chips, coolant, and dust depending on material.

- Laser cutting involves laser safety, smoke/ fumes, and reflective material considerations.

Precision and Quality

Laser cutters typically offer superior edge quality on appropriate materials, with minimal finishing required. They can achieve very fine details and intricate patterns that would be impossible with CNC routing.

CNC machines provide excellent precision but may require sanding or finishing. They can create features that lasers cannot, such as threaded holes, complex 3D surfaces, and precise dimensional pockets.

Speed Considerations

Laser cutting is generally faster for 2D cuts, especially on thin materials and complex shapes with many curves or small details.

CNC routing can be faster for thick materials, large-scale material removal, and when multiple operations (cutting, drilling, pocketing) are needed on the same piece.

Design Flexibility

CNC machines offer true 3D capability, can create undercuts, and work well for mechanical parts requiring precise fits and assemblies.

Laser cutters are primarily 2D tools but excel at creating complex patterns, living hinges, and parts that nest efficiently for minimal waste.

Cost and Maintenance

Entry-level laser cutters often have lower initial costs ($3,000-15,000) compared to comparable CNC systems ($5,000-25,000+). However, lasers require consumables like laser tubes and lenses, while CNCs need cutting tool replacements.

The choice between them often comes down to your specific applications, materials, and whether you need 3D capability versus the precision and speed of laser cutting. Many shops find both tools complementary rather than competitive.

What types of projects are you considering, and what materials do you plan to work with primarily?

Conclusion

CNC machining and laser cutting are complementary technologies that empower a wide range of fabrication tasks. By understanding the strengths and limitations of each method—and considering a hybrid approach when appropriate—you can optimize parts quality, throughput, and overall production efficiency. Whether you’re building prototypes, fabricating parts, or running a small production line, selecting the right combination of CNC and laser cutting capabilities will drive better outcomes.

Leave a Reply

You must be logged in to post a comment.