Can the laser cutting machine cut wooden boards?

Today, most felled wood is made in the form of traditional saw blades, but they generate a lot of pollution, such as wood chips and noise. Wood laser cutting machine can not only reduce noise, but also reduce the production of wood pellets. The quality of laser-cut wood chips is also better than traditional cutting methods. The cut surface is rough, broken or damaged wood grain is not obvious, but covered with a thin burnt layer.

There are two basic methods of wood laser cutting machine: flashing and burning. Flash steaming is the ideal method for cutting wood. The wood evaporates under the irradiation of a focused laser beam, forming seams. The characteristics of deflation cutting are high cutting speed, low heat transfer to the uncut substrate, no carbonization of the profile and only a small amount of black enamel.

The main causes of fire are the low power density of the beam, slow cutting speed, wide slits, large cutting thickness, and the smell of smoke and burning. The energy consumption per unit of burning and cutting materials is higher than the energy consumption of gasification, and there is carbonization at the tip. However, in the actual logging process, gasification is mainly accompanied by combustion. In fact, despite the advantages of high efficiency in the gasification process, high power density is required to achieve it.

However, in the actual laser irradiation process, due to the influence of the laser output power and beam mode, the laser power density is usually less than the power density required to vaporize the laser surface. In addition, wood laser cutting machine also requires auxiliary airflow coaxial with the beam, which is usually air or low-pressure inert gas.

What kind of laser machine can cut wood?

Generally, CO2 laser machine is used to cut wood, and its wavelength is 10.6μM, but the photoelectric conversion rate of CO2 laser is low (only 5%~10%) and high power consumption. Need frequent ventilation and low maintenance cost. The higher external light path is complicated and difficult to install, debug and maintain. Therefore, CO2 laser have limited production and practical industrial applications.

Currently, the commonly used fiber laser machine (wavelength of 1μm) on the market can cut metal plates. So can this fiber laser machine cut wood? The answer is: more difficult. This is because wood absorbs laser light having a relatively low wavelength of 1 μm, and it is difficult to form slits.

Comment (1)

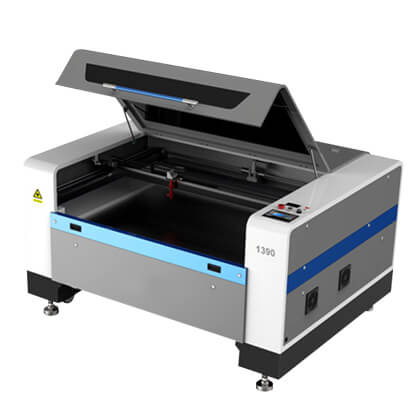

CO2 laser engraving machine is equipped with a precision water cooled CO2 laser which can engrave on almost any non-metal materials surface. The CO2 laser engraver machine can also be used for cutting many different materials. With the cylinder rotary attachment, you can engrave any cylindrical object, such as cup, brush pot, musical instrument, and so on. The CO2 laser engraving system supports multiple graphic formats, such as PLT, DXF, BMP, JPG, GIF, PGN, TIF, and so on. The CO2 laser machine is equipped with DSP control system for CorelDraw, AutoCAD and other advanced software.The CO2 laser engraver is compatible with WIN10, WIN8, WIN7, Windows Vista and Windows XP.