Advantages of CNC Cutting Nesting Machine

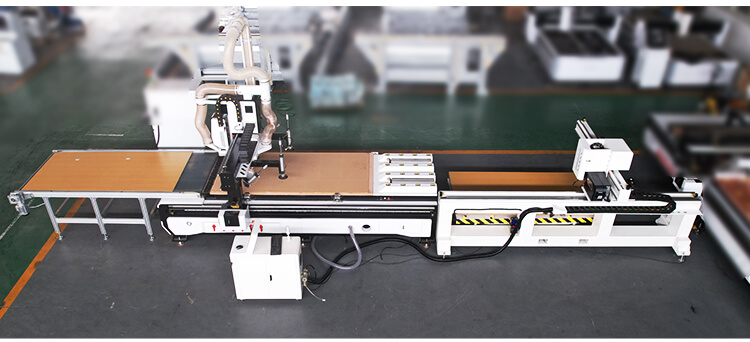

CNC cutting machine, also collectively referred to as intelligent panel furniture production line equipment. As the name implies, all processes from the board’s loading, cutting, vertical hole drilling, and blanking are done in one go. It perfectly replaces manual production and processing. Therefore, many people also call it CNC cutting machine, woodworking cutting machine and so on. So, what are the significant advantages and processing techniques of the CNC cutting machine for traditional furniture manufacturing equipment?

Advantages of CNC Cutting Nesting Machine

- Enhanced Material Efficiency: The CNC cutting nesting machine utilizes advanced software algorithms to nest multiple parts on a single sheet of material, minimizing waste and maximizing the utilization of raw materials. This results in cost savings and eco-friendly practices by reducing scrap and optimizing material usage.

- Precision Cutting: With its computer-controlled precision, the CNC cutting nesting machine ensures accurate and consistent cutting of various materials, from wood and metal to plastics and composites. This level of precision leads to high-quality finished products with tight tolerances and intricate details.

- Increased Productivity: By automating the cutting process and optimizing the layout of parts on a sheet of material, the CNC cutting nesting machine streamlines production workflows and reduces manual labor. This efficiency translates into higher productivity rates, faster turnaround times, and increased output for manufacturing operations.

- Versatile Applications: The CNC cutting nesting machine is capable of cutting a wide range of materials and shapes, making it suitable for diverse industries such as cabinet making, automotive, aerospace, and packaging. Its versatility allows for the creation of custom designs, prototypes, and mass-produced components with ease.

- Customization and Flexibility: The CNC cutting nesting machine offers flexibility in design customization, allowing for the creation of unique patterns, shapes, and sizes tailored to specific project requirements. This customization capability enables manufacturers to meet individual customer needs and adapt to changing market demands.

Key Considerations for Selecting the Optimal CNC Cutting Nesting Machine

As you explore the integration of CNC cutting nesting technology into your fabrication operations, there are several critical factors to consider:

- Material Compatibility: Ensure that the CNC cutting nesting machine is designed to handle the specific materials you work with, considering factors such as thickness, composition, and cutting requirements.

- Cutting Precision and Quality: Prioritize machines that offer the highest levels of cutting precision and the ability to produce clean, consistent edges on your fabricated components.

- Automation and Workflow Integration: Look for CNC cutting nesting machines that seamlessly integrate with your existing production workflows, including material handling systems and design software.

- Ease of Use and Operator Training: Evaluate the user-friendliness of the machine’s interface and the availability of comprehensive training resources to ensure a smooth adoption process for your workforce.

- Scalability and Future-Proofing: Consider the growth trajectory of your business and select a CNC cutting nesting machine that can scale to accommodate your evolving fabrication needs.

In essence, the CNC cutting nesting machine stands as a beacon of efficiency, precision, and innovation in the realm of manufacturing and fabrication. By harnessing its advantages, craftsmen and industrial operators can optimize material usage, enhance productivity, and unlock new possibilities in creating high-quality products with speed and accuracy.

If you are considering incorporating a CNC cutting nesting machine into your production processes or have specific questions about its capabilities and applications, feel free to share your inquiries, and I shall provide further insights and guidance to help you harness the full potential of this remarkable machine in your manufacturing endeavors.

Leave a Reply

You must be logged in to post a comment.