Glass Edging Machine: Precision Engineering for Flawless Glass Finishes

In the world of glass fabrication, achieving perfect edges is critical for both safety and aesthetics. This is where the glass edging machine proves indispensable. Designed to deliver smooth, polished, and precisely shaped edges, a high-quality glass edging machine has become essential for manufacturers, glaziers, and glass artisans worldwide.

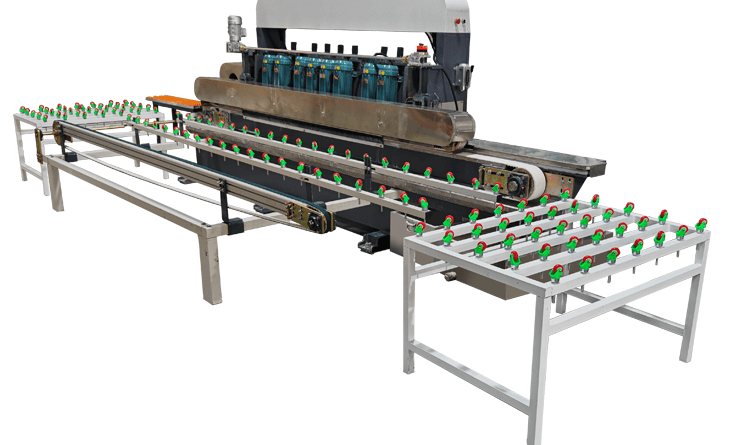

Glass Edging Machine

The Straight Line Beveller is a fully automatic bevelling machine with 9 spindles – 2 diamond wheels for bevel grinding, 3 resin wheels and 3 felt wheels for bevel polishing, and 1 edging wheel for cleaning up the edge. Bevel parameters are input at the control panel and servo adjustments are made automatically.

The modern glass edging machine combines advanced technology with robust construction to handle various glass types and thicknesses. From straight edges to intricate bevels, these machines utilize diamond grinding wheels and precision calibration to produce consistent results. Whether processing tempered glass for skyscrapers or decorative glass for home interiors, a reliable glass edging machine ensures professional-grade finishes every time.

Automation features in today’s glass edging machine models significantly enhance productivity. Programmable settings allow for quick changeovers between different edge profiles, while intelligent sensors maintain optimal pressure and speed during operation. Many industrial-grade glass edging machine units now incorporate water recycling systems, making them more environmentally friendly and cost-effective to operate.

For businesses looking to improve their glass processing capabilities, investing in a high-performance glass edging machine can dramatically reduce labor costs while increasing output quality. As glass applications continue to diversify across industries, these machines remain at the forefront of fabrication technology.

Leave a Reply

You must be logged in to post a comment.