Laser Cut Aluminum: The Best Practices for Precision and Efficiency

In the dynamic world of metal fabrication, the laser cutting of aluminum has emerged as a transformative technology, offering unparalleled precision, speed, and versatility. As manufacturers and fabricators seek to elevate their production capabilities, mastering the best practices for laser cutting aluminum has become a critical imperative. By understanding the nuances of this advanced process, you can unlock a new era of efficiency, quality, and competitiveness in your metal fabrication operations.

Laser Cutting Aluminum

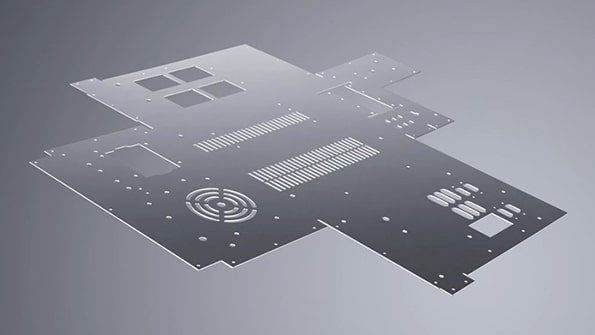

Laser cutting aluminum is a manufacturing process that uses a high-powered and tightly focused laser beam. This is to precisely cut aluminum sheets or plates to exactly match CAD-specified shapes or patterns. It is a critically important method for metal fabrication, offering major advantages over more traditional cutting techniques. Laser cutting aluminum is common in various industries, including aerospace, automotive, electronics, signage, and architectural applications. It offers a precise and efficient method for cutting aluminum with high quality and consistency.

The Power of Laser Cutting Aluminum

Laser-cutting aluminum has revolutionized the way we approach metalworking. This precision-driven technique harnesses the power of focused light to create intricate designs, clean cuts, and complex shapes in aluminum sheets and components. The relevance of laser cutting aluminum in modern manufacturing cannot be overstated, as it offers unparalleled accuracy, speed, and flexibility compared to traditional cutting methods.

From aerospace and automotive industries to architectural applications and consumer electronics, laser-cut aluminum components are ubiquitous in our daily lives. The ability to quickly prototype and produce custom parts with minimal material waste has made laser cutting an indispensable tool for engineers, designers, and manufacturers alike.

Our aluminum laser cutting machine is designed for high-precision cutting of aluminum and aluminum alloys, delivering exceptional performance for a variety of industrial applications. Equipped with advanced laser technology, this machine ensures smooth, clean edges and minimal material distortion, making it ideal for industries such as automotive, aerospace, electronics, and manufacturing.

Built for speed and accuracy, the aluminum laser cutting machine features a powerful laser source, a robust motion control system, and a user-friendly interface for seamless operation. Whether you’re cutting complex shapes, intricate designs, or large sheets, this machine offers unmatched versatility and reliability. Its automated features minimize downtime, optimize cutting efficiency, and reduce operational costs, providing significant value for high-volume production environments.

With an emphasis on durability and energy efficiency, the aluminum laser cutting machine is engineered to offer long-term operational excellence while maintaining environmental sustainability. Whether you’re looking to enhance your production capacity or improve cutting precision, this machine is the perfect solution for businesses seeking cutting-edge technology and superior results.

Advantages of Fiber Laser Cutting Technology

Fiber lasers offer several advantages that make them particularly well-suited for cutting aluminum:

-

High-power density: Fiber lasers can focus their energy into a very small spot, allowing for efficient cutting even with reflective materials like aluminum.

-

Fast cutting speeds: The high power and excellent beam quality of fiber lasers enable rapid cutting, increasing productivity.

-

Minimal heat-affected zone: Fiber lasers produce less heat than other laser types, resulting in cleaner cuts with less thermal distortion.

-

Versatility: These lasers can cut a wide range of aluminum thicknesses and alloys, making them suitable for various applications.

Difficulties of Aluminum and Laser Processing

When you project light onto a reflective material, it bounces back or scatters. So when the light of a laser beam makes contact with aluminum, the tendency is for it to bounce or scatter as well. This can make laser cutting difficult.

Solid and stable molecular structures are easier to cut through than softer ones. Because aluminum’s molecular structure is more malleable, the laser beam is not as effective at piercing through it and creating clean cuts.

Finally, aluminum is a heat conductive material. As such, it quickly absorbs heat, which is needed for clean cutting. Also, when you dissipate the heat it makes smooth laser processing difficult.

All of these reasons are why laser cutting aluminum is difficult. But just because something is difficult doesn’t mean we can’t do it. Over the years, we’ve fine-tuned our aluminum cutting capabilities to make it an easy and effective process.

Key Factors and Considerations for Successful Aluminum Laser Cutting

To achieve the best results when laser cutting aluminum, keep these factors in mind:

-

Assist Gas Selection: Nitrogen is often preferred for cutting aluminum, as it produces oxide-free cuts. Oxygen can be used for thicker materials but may result in an oxidized edge.

-

Focus Position: Experiment with the focus position relative to the material surface. A slight positive or negative focus can sometimes improve cut quality.

-

Cutting Speed Optimization: Finding the right balance between cutting speed and power is crucial. Too slow, and you risk excessive heat input; too fast, and you may not achieve full penetration.

-

Material Cleanliness: Ensure your aluminum sheets are clean and free from oils or contaminants that could affect cut quality.

-

Thermal Management: For larger jobs, consider implementing a cooling system or allowing periodic cool-down intervals to prevent heat buildup in the material.

-

Edge Quality Control: Monitor edge quality throughout the cutting process. Adjust parameters if you notice issues like dross formation or excessive melting.

Laser Aluminum Cutting Thickness Reference

| Laser Power | Thickness (mm) | Cutting Speed (m/min) | Focus Position (mm) | Cutting Height (mm) | Gas | Nozzle (mm) | Pressure (bar) |

|---|---|---|---|---|---|---|---|

| 1000W | 0.8 | 18 | 0 | 0.8 | N2 | 1.5S | 12 |

| 1 | 10 | 0 | 0.5 | N2 | 1.5S | 12 | |

| 2 | 5 | -1 | 0.5 | N2 | 2.0S | 14 | |

| 3 | 1.5 | -1.5 | 0.5 | N2 | 3.0S | 16 | |

| 1500W | 1 | 18 | 0 | 0.5 | N2 | 1.5S | 12 |

| 2 | 6 | -1 | 0.5 | N2 | 2.0S | 14 | |

| 3 | 2.5 | -1.5 | 0.5 | N2 | 2.5S | 14 | |

| 4 | 0.8 | -2 | 0.5 | N2 | 3.0S | 16 | |

| 2000W | 1 | 20 | 0 | 0.8 | N2 | 1.5S | 12 |

| 2 | 10 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 4 | -1.5 | 0.5 | N2 | 2.0S | 14 | |

| 4 | 1.5 | -2 | 0.5 | N2 | 2.5S | 14 | |

| 5 | 0.9 | -2.5 | 0.5 | N2 | 3.0S | 16 | |

| 6 | 0.6 | -3 | 0.5 | N2 | 3.0S | 16 | |

| 3000W | 1 | 25-30 | 0 | 0.8 | N2 | 1.5S | 12 |

| 2 | 15-18 | 0 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 7.0-8.0 | -1 | 0.5 | N2 | 2.0S | 14 | |

| 4 | 5.0-6.0 | -2 | 0.5 | N2 | 2.5S | 14 | |

| 5 | 2.5-3.0 | -3 | 0.5 | N2 | 3.0S | 16 | |

| 6 | 1.5-2.0 | -3.5 | 0.5 | N2 | 3.0S | 16 | |

| 8 | 0.6-0.7 | -4 | 0.5 | N2 | 3.5S | 16 | |

| 4000W | 1 | 25-30 | 0 | 0.6 | N2 | 1.5S | 12 |

| 2 | 16-20 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 10-13 | -1.5 | 0.5 | N2 | 2.0S | 14 | |

| 4 | 6.0-7.0 | -2 | 0.5 | N2 | 2.5S | 14 | |

| 5 | 4.0-5.0 | -2.5 | 0.5 | N2 | 2.5S | 14 | |

| 6 | 2.5-3.0 | -3 | 0.5 | N2 | 3.0S | 16 | |

| 8 | 1.0-1.3 | -4 | 0.5 | N2 | 3.0S | 16 | |

| 10 | 0.8 | -5 | 0.5 | N2 | 3.5S | 16 | |

| 6000W | 1 | 30-45 | 0 | 1 | N2 | 1.5S | 12 |

| 2 | 20-25 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 14-16 | -1.5 | 0.5 | N2 | 2.5S | 14 | |

| 4 | 8.0-10.0 | -2 | 0.5 | N2 | 2.5S | 14 | |

| 5 | 5.0-6.0 | -3 | 0.5 | N2 | 3.0S | 14 | |

| 6 | 3.5-4.0 | -3 | 0.5 | N2 | 3.0S | 16 | |

| 8 | 1.5-2.0 | -4 | 0.5 | N2 | 3.0S | 16 | |

| 10 | 1.0-1.2 | -4.5 | 0.5 | N2 | 3.5S | 18 | |

| 12 | 0.6-0.7 | -5 | 0.5 | N2 | 4.0S | 18 | |

| 14 | 0.4-0.6 | -5 | 0.3 | N2 | 4.0S | 18 | |

| 16 | 0.3-0.4 | -8 | 0.3 | N2 | 5.0S | 20 | |

| 8000W | 1 | 40-45 | 0 | 0.8 | N2 | 2.0S | 12 |

| 2 | 25-30 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 22-25 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 4 | 12-15 | -2 | 0.5 | N2 | 2.0S | 12 | |

| 5 | 8.0-10.0 | -3 | 0.5 | N2 | 2.5S | 14 | |

| 6 | 6.0-7.0 | -3 | 0.5 | N2 | 2.5S | 14 | |

| 8 | 3.5-4.0 | -4 | 0.5 | N2 | 2.5S | 14 | |

| 10 | 2.0-2.5 | -5 | 0.5 | N2 | 5.0B | 14 | |

| 12 | 1.6-2.0 | -5 | 0.5 | N2 | 5.0B | 16 | |

| 14 | 1.0-1.2 | -6 | 0.5 | N2 | 5.0B | 16 | |

| 16 | 0.8-1.0 | -7 | 0.5 | N2 | 5.0B | 16 | |

| 18 | 0.7-0.8 | -8 | 0.5 | N2 | 5.0B | 16 | |

| 20 | 0.5-0.6 | -9 | 0.3 | N2 | 7.0B | 16 | |

| 25 | 0.4-0.5 | -10 | 0.3 | N2 | 7.0B | 16 | |

| 30 | 0.2 | +7 | 0.3 | N2 | 7.0B | 18 | |

| 10KW | 1 | 45-50 | 0 | 0.8 | N2 | 2.0S | 12 |

| 2 | 25-30 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 20-25 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 4 | 18-20 | -2 | 0.5 | N2 | 2.0S | 12 | |

| 5 | 14-16 | -3 | 0.5 | N2 | 2.5S | 14 | |

| 6 | 8.0-9.0 | -3 | 0.5 | N2 | 2.5S | 14 | |

| 8 | 5.0-6.0 | -4 | 0.5 | N2 | 2.5S | 14 | |

| 10 | 4.0-4.5 | -5 | 0.5 | N2 | 5.0B | 14 | |

| 12 | 1.6-2.0 | -5 | 0.5 | N2 | 5.0B | 16 | |

| 14 | 1.2-1.5 | -5 | 0.5 | N2 | 5.0B | 16 | |

| 16 | 1.0-1.2 | -5 | 0.5 | N2 | 5.0B | 16 | |

| 18 | 0.8-1.0 | -5 | 0.5 | N2 | 5.0B | 16 | |

| 20 | 0.6-0.8 | -5 | 0.3 | N2 | 7.0B | 16 | |

| 25 | 0.5-0.6 | -5 | 0.3 | N2 | 7.0B | 16 | |

| 30 | 0.25-0.45 | +7 | 0.3 | N2 | 7.0B | 18 | |

| 40 | 0.15-0.2 | +8 | 0.3 | N2 | 7.0B | 18 | |

| 12KW | 1 | 45-50 | 0 | 0.8 | N2 | 2.0S | 12 |

| 2 | 30-35 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 20-25 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 4 | 18-20 | -2 | 0.5 | N2 | 2.0S | 12 | |

| 5 | 14-16 | -3 | 0.5 | N2 | 2.5S | 14 | |

| 6 | 10-12 | -3 | 0.5 | N2 | 2.5S | 14 | |

| 8 | 6.0-8.0 | -4 | 0.5 | N2 | 2.5S | 14 | |

| 10 | 4.0-6.0 | -5 | 0.5 | N2 | 5.0B | 14 | |

| 12 | 2.0-3.0 | -5 | 0.5 | N2 | 5.0B | 16 | |

| 14 | 1.5-2.5 | -5 | 0.5 | N2 | 5.0B | 16 | |

| 16 | 1.3-2.0 | -5 | 0.5 | N2 | 5.0B | 16 | |

| 18 | 1.0-1.6 | -5 | 0.5 | N2 | 5.0B | 16 | |

| 20 | 0.8-1.2 | -5 | 0.3 | N2 | 7.0B | 16 | |

| 25 | 0.5-0.7 | -5 | 0.3 | N2 | 7.0B | 16 | |

| 30 | 0.25-0.3 | +7 | 0.3 | N2 | 7.0B | 18 | |

| 40 | 0.15-0.2 | +8 | 0.3 | N2 | 7.0B | 18 | |

| 15KW | 1 | 48-52 | 0 | 0.8 | N2 | 2.0S | 12 |

| 2 | 35-38 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 25-27 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 4 | 20-22 | -2 | 0.5 | N2 | 2.0S | 12 | |

| 5 | 15-17 | -3 | 0.5 | N2 | 2.5S | 14 | |

| 6 | 12-14 | -3 | 0.5 | N2 | 2.5S | 14 | |

| 8 | 8.0-9.0 | -4 | 0.5 | N2 | 2.5S | 14 | |

| 10 | 5.0-7.0 | -5 | 0.5 | N2 | 5.0B | 14 | |

| 12 | 2.5-3.5 | -5 | 0.5 | N2 | 5.0B | 16 | |

| 14 | 2.0-3.0 | -5 | 0.5 | N2 | 5.0B | 16 | |

| 16 | 1.5-2.5 | -5 | 0.5 | N2 | 5.0B | 16 | |

| 18 | 1.3-1.8 | -5 | 0.5 | N2 | 5.0B | 16 | |

| 20 | 0.8-1.2 | -5 | 0.3 | N2 | 7.0B | 18 | |

| 25 | 0.5-0.7 | -5 | 0.3 | N2 | 7.0B | 18 | |

| 30 | 0.4-0.5 | -7 | 0.3 | N2 | 7.0B | 20 | |

| 40 | 0.25-0.3 | +8 | 0.3 | N2 | 7.0B | 20 | |

| 50 | 0.2-0.25 | +9 | 0.3 | N2 | 8.0B | 20 | |

| 20KW | 1 | 55-60 | 0 | 0.8 | N2 | 2.0S | 8 |

| 2 | 40-45 | -1 | 0.5 | N2 | 2.0S | 8 | |

| 3 | 30-35 | -1 | 0.5 | N2 | 2.5S | 10 | |

| 4 | 25-30 | -2 | 0.5 | N2 | 2.5S | 12 | |

| 5 | 18-20 | -3 | 0.5 | N2 | 3.0S | 14 | |

| 6 | 16-18 | -3 | 0.5 | N2 | 3.0S | 14 | |

| 8 | 10-12 | -4 | 0.5 | N2 | 3.5S | 14 | |

| 10 | 9.0-10.0 | -5 | 0.5 | N2 | 3.5S | 14 | |

| 12 | 5.0-6.0 | -6 | 0.3 | N2 | 5.0B | 16 | |

| 14 | 4.0-5.0 | -7 | 0.3 | N2 | 5.0B | 16 | |

| 16 | 3.0-4.0 | -7 | 0.3 | N2 | 5.0B | 16 | |

| 18 | 2.0-3.0 | -7 | 0.3 | N2 | 5.0B | 16 | |

| 20 | 1.5-2.0 | -7 | 0.3 | N2 | 6.0B | 18 | |

| 25 | 1.0-1.2 | -7.5 | 0.3 | N2 | 6.0B | 18 | |

| 30 | 0.8-1.0 | -7.5 | 0.3 | N2 | 7.0B | 20 | |

| 40 | 0.5-0.8 | -9 | 0.3 | N2 | 7.0B | 20 | |

| 50 | 0.4-0.6 | -9 | 0.3 | N2 | 8.0B | 20 | |

| 60 | 0.2-0.3 | -9 | 0.3 | N2 | 8.0B | 20 | |

| 30KW | 1 | 55-60 | 0 | 0.8 | N2 | 2.0S | 8 |

| 2 | 40-45 | -1 | 0.5 | N2 | 2.0S | 8 | |

| 3 | 30-35 | -1 | 0.5 | N2 | 2.5S | 10 | |

| 4 | 25-30 | -2 | 0.5 | N2 | 2.5S | 12 | |

| 5 | 18-25 | -3 | 0.5 | N2 | 3.0S | 14 | |

| 6 | 18-20 | -3 | 0.5 | N2 | 3.0S | 14 | |

| 8 | 15-18 | -4 | 0.5 | N2 | 3.5S | 14 | |

| 10 | 12-15 | -5 | 0.5 | N2 | 3.5S | 14 | |

| 12 | 10-12 | -6 | 0.3 | N2 | 5.0B | 16 | |

| 14 | 8.0-10.0 | -7 | 0.3 | N2 | 5.0B | 16 | |

| 16 | 6.0-8.0 | -7 | 0.3 | N2 | 5.0B | 16 | |

| 18 | 3.0-4.0 | -7 | 0.3 | N2 | 5.0B | 16 | |

| 20 | 2.0-3.0 | -7 | 0.3 | N2 | 6.0B | 18 | |

| 25 | 1.5-2.0 | -7.5 | 0.3 | N2 | 6.0B | 18 | |

| 30 | 0.8-1.0 | -7.5 | 0.3 | N2 | 7.0B | 20 | |

| 40 | 0.5-0.8 | -9 | 0.3 | N2 | 7.0B | 20 | |

| 50 | 0.4-0.6 | -9 | 0.3 | N2 | 8.0B | 20 | |

| 60 | 0.2-0.3 | -9 | 0.3 | N2 | 8.0B | 20 |

How to Cut Aluminum with Laser?

- Design and Programming: Design the cutting pattern according to the product requirements and write or import the control program of the laser cutting machine.

- Material preparation: Place the aluminum material on the cutting platform and make sure it is fixed and stable.

- Laser Setting: Set the laser power, speed, focal length and other parameters according to the thickness and characteristics of the aluminum material.

- Auxiliary gas: Enable the nitrogen supply to help the cutting process.

- Start cutting: Start the laser cutting machine and cut according to the program.

- Monitoring and Adjustment: Monitor the cutting quality during the cutting process and adjust the parameters as needed.

- Post-processing: After cutting is complete, check the cut quality and remove any residual slag or burrs.

Unlocking the Full Potential of Laser Cut Aluminum

By embracing the best practices for laser cutting aluminum, you can unlock a new level of productivity, quality, and competitiveness in your metal fabrication operations. Some key benefits include:

- Elevated Precision and Consistency: Consistent adherence to the best practices for laser cutting aluminum ensures that every part produced meets the tightest tolerances and maintains the desired level of quality.

- Increased Throughput and Efficiency: Optimizing the laser cutting parameters and workflow can significantly enhance your productivity, allowing you to take on more projects and meet tighter deadlines.

- Cost Savings and Sustainability: Minimizing material waste, reducing the need for post-processing, and streamlining your overall fabrication process can lead to substantial cost savings and a more environmentally-friendly operation.

- Expanded Capabilities and Diversification: Mastering the art of laser cutting aluminum empowers you to tackle a wider range of projects, diversify your product offerings, and better serve the evolving needs of your customers.

- Improved Competitive Advantage: By delivering superior-quality, precision-engineered aluminum components, you can strengthen your brand reputation and position your business as a leader in the metal fabrication industry.

Discover unparalleled precision with our Aluminium Laser Cutting Machine, designed for efficiency and accuracy in metal fabrication. Engineered specifically for aluminium, this machine delivers clean cuts and minimal waste, enhancing productivity. Ideal for both small and large-scale operations, it offers advanced features and easy operation, making it perfect for various applications in diverse industries. With robust construction, it ensures durability and long-lasting performance. Optimize your workflow and achieve superior results with this cutting-edge aluminium laser cutting technology.

Types of Lasers Suitable for Cutting Aluminum

Generally speaking, fiber lasers, CO2 lasers, and other solid-state lasers can cut metal.

Fiber Lasers

Fiber lasers are highly effective for cutting aluminum due to their powerful energy density and precise beam quality. They can focus energy into a very small spot, allowing for precise and efficient sheet metal cutting, even with reflective materials like aluminum.

Advantages of Fiber Lasers

- High Efficiency and Speed: Fiber lasers convert energy efficiently and achieve rapid cutting speeds, boosting productivity.

- Minimal Heat-Affected Zones: The focused energy results in minimal thermal deformation of the material.

- Versatility: Fiber lasers can cut various thicknesses and alloys of aluminum, making them suitable for a wide range of applications.

Crystal Lasers (Nd: YAG and Nd: YVO4)

Crystal lasers, such as Nd: YAG and Nd: YVO4, share similar wavelengths with fiber lasers, making them suitable for cutting aluminum sheets. These lasers are often used in applications where fiber lasers are either unavailable or not required.

Features of Crystal Lasers

- Precision Cutting: They offer precise cutting capabilities, suitable for detailed work.

- High Beam Quality: These lasers provide excellent beam quality, essential for clean cuts.

- Flexibility: Crystal lasers can be used in various industrial applications where high precision is needed.

CO2 Lasers

CO2 lasers are another type of laser used in cutting applications, though they are generally less efficient for cutting aluminum due to the material’s high reflectivity and thermal conductivity.

Limitations of CO2 Lasers

- Reflectivity: Aluminum’s reflectivity scatters CO2 laser beams, lowering their effectiveness.

- Thermal Conductivity: Aluminum dissipates heat quickly, requiring higher laser power and speed to achieve clean cuts.

- Application Suitability: CO2 lasers are more commonly used for non-metallic materials like wood and acrylic, where they perform exceptionally well.

Leave a Reply

You must be logged in to post a comment.