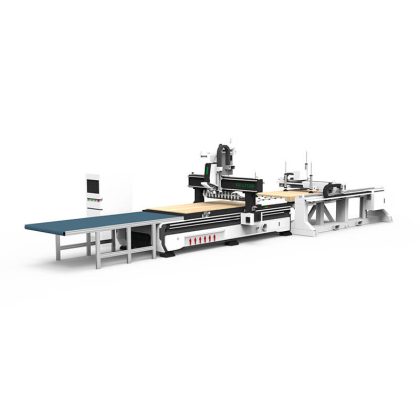

Automatic Labeling CNC Drilling and Cutting Furniture Machine

Item No:iGC-LT

The automatic CNC drilling and labeling machine is specially designed for the wood processing industry and can efficiently and accurately label and drill wood panels. This equipment combines advanced CNC technology with an intelligent automation system to provide an integrated processing solution for the furniture manufacturing, woodworking, building materials and other industries, significantly improving production efficiency and product quality.

Price Range: $40000-$50000

Category: Cabinet Maker

Description

Automatic Labeling CNC Drilling and Cutting Furniture Production Line

Function

Automatic labeling, automatic slotting, automatic punching, automatic material cutting, automatic pushing, door panel engraving

The Automatic CNC Drilling and Labeling Machine is a state-of-the-art solution designed specifically for the wood processing industry. It combines advanced CNC technology with intelligent automation to efficiently and accurately mark and drill wood panels. Ideally suited to the furniture manufacturing, carpentry and construction industries, the machine is capable of high-speed, fully automated production with extreme precision. Key features include integrated marking and drilling, support for a wide range of sizes and types of wood, and a dust protection system to ensure clean, safe operation. This cutting-edge machine increases your productivity, reduces labor costs and ensures high-quality output.

Equipment parameters

| Technical indicators | parameter |

| Model | iGC-LT1325 |

| Working area(X,Y,Z) | 1300*2500*250mm |

| Max. working speed | 30000mm/min |

| Bed | Heavy-duty bed welded with square tubes, aging annealed, no deformation |

| Spindle Power | 9.0kw air-cooled tool change spindle, 24000rpm |

| mesa | PVC vacuum adsorption table |

| Rack | Taiwan Hiwin guide rail + YYC high-precision rack + hard helical gear shaft |

| Lead Screw | Taiwan TBI grinding screw |

| Drive motor | High power servo motor + Z-axis brake |

| Reducer | SHIMPO |

| Frequency Converter | Fuling |

| Vacuuming | 4KW double barrel vacuum cleaner |

| Vacuum Pump | 5.5KW air-cooled vacuum pump |

| Standard | Positioning cylinder + push device + secondary dust removal + suction cup + three-color light + tool setting instrument + tool lock seat |

| Control cabinet | IGOLDEN independent electric control cabinet |

| Tool magazine | Inline knife changer with 12 knives (16 knives can be customized) |

| Control System | Taiwan LNC/SYNTEC system (optional) + handle |

| Lubrication system | Automatic oil filling |

| Repeat positioning accuracy | 0.02mm |

| Command language | G Code |

| Operating voltage | AC220V/380V, 50Hz |

Applicable industries and scenarios

- Furniture manufacturing: Suitable for labeling and drilling of solid wood and panel furniture, greatly improving production efficiency and processing accuracy.

- Woodworking processing: Provides a one-stop service for high-precision handling needs such as splicing and installation openings.

- Structural panels: Can be used for drilling and labeling identification of structural wood panels, assisting in quick setup and management on the building and construction site.

How It Works

The machine uses a series of intelligent systems to collaborate to complete wood processing:

- Material transport and positioning: The intelligent transport system feeds the timber into the processing area, and the positioning system automatically adjusts the timber to the set position to ensure the accuracy of subsequent operations.

- Intelligent labling: The system quickly classifies the surface of the wood according to pre-set requirements, which can be size, production number or handling instructions, to facilitate identification and procedures in subsequent manufacturing operations.

- Specific drilling: Equipped with a CNC-controlled drilling unit, holes can be drilled in the wood according to manufacturing requirements. The position and depth of the holes can be accurately controlled to meet various processing requirements such as holes for connecting furniture parts and installation holes.

- Centralized control system: The machine adopts an advanced PLC control system combined with a touch screen interface, which can adjust and monitor the operation of the machine in real time to ensure easy operation and stable production.

- Cooling and dust removal system: During the drilling process, the cooling system effectively prevents high temperatures from damaging the machine or the wood. At the same time, the dust removal system will promptly clean up the wood shavings and dust generated by drilling to keep the working environment clean and extend the life of the machine.

- Finished product output: The finished wood is smoothly discharged through an automatic output device, which facilitates subsequent finishing and logistics operations.

Key Features

Optimized design for wood processing: This production line is dedicated to wood processing and can accurately complete labeling and drilling tasks according to the size, thickness and texture of different types of wood, whether it is solid wood, composite wood or plywood.

Fully automated production: The entire process is automated, including the transportation, precise positioning, labeling, drilling and output of finished products, completely eliminating the need for manual intervention, significantly reducing labor costs and improving production efficiency.

CNC high-precision processing: Equipped with a computer numerical control (CNC) system, it ensures high precision and consistency in drilling and labeling operations, and is particularly suitable for scenarios such as furniture manufacturing where processing accuracy is strictly required.

Labeling and drilling integration: The machines can perform wood marking and drilling operations at the same time. The labeling function can note the size or number of the wood, which is convenient for subsequent handling and logistics management; the drilling function supports a variety of hole specifications to meet different production requirements.

Ideal for a variety of log sizes: The machine supports adaptable setup of a variety of wood sizes, densities and processing needs, and can be customized according to detailed production requirements. It is widely used in furniture panel processing, woodworking assembly lines and other areas.

Combining high efficiency and environmental protection: The machine is equipped with a cooling system, dust prevention device and intelligent safety protection functions to ensure efficient production while maintaining a clean processing environment and protecting the safety of operators.

Related Products

FAQ

Sure. You can customize not only the size of the machine but also many other configurations.

Automatic CNC drilling and labeling machines are intelligent equipment specially designed for wood processing, and are widely used in furniture manufacturing, woodworking decoration, and building wood structures. They integrate efficient drilling and precise labeling, and are specially designed to optimize the characteristics of wood. They not only improve processing accuracy, but also greatly improve production efficiency. The following are the main applications of this equipment in wood processing:

This machine is particularly important in the furniture manufacturing industry and can be used to produce a variety of modular furniture, custom cabinets, wardrobes and wooden decorations.

- Efficient drilling: It can quickly complete the processing of connectors, dowel holes, hinge holes, etc., ensuring accurate hole positions and meeting complex assembly needs.

- Automatic labeling: Each component is marked with a serial number, installation direction or customer information to facilitate subsequent assembly and logistics management. It is particularly suitable for mass customization (CNC furniture manufacturing).

Woodworking and Decoration Industry

In the woodworking and decoration industry, automatic CNC drilling and labeling machines provide efficient processing solutions for a variety of decorative panels.

- Decorative panel processing: For example, drilling panels for background walls, ceilings and decorative partitions.

- Marking and sorting: Labels are used to identify different sizes of panels, avoiding assembly errors caused by material mix-ups and improving construction efficiency.

Door and Window Production

In the manufacture of wooden doors and windows, the machine’s precise drilling function can quickly complete the processing of door lock holes, hinge holes and connector holes.

- Standardized processing: ensures that the dimensions of the door and window components are consistent, improving product quality.

- Labeling: the labeling function makes it easy to identify different specifications of door and window parts, and is especially suitable for mass production.

Building Wood Processing

The machine provides efficient drilling and labeling services for components such as beams, columns and panels in building wood structures.

- Structural component drilling: such as perforations for fixed connections, support holes, etc., to ensure dimensional accuracy to meet construction needs.

- Construction labeling: labeling to indicate the location number or installation instructions for building components simplifies the construction process and improves on-site efficiency.

Panel Assembly and Packaging Material Production

The machine is also suitable for processing panels and wooden packaging materials.

- Panel processing: provides precise drilling for large-size assembled panels, suitable for the manufacture of office furniture, display cabinets and other products.

- Customized packaging: drills holes in wooden packaging boxes and labels them with shipping information or barcodes to meet the needs of modern logistics.

Staircase Manufacturing

The handrails, treads and supporting structures in stair manufacturing require high-precision drilling. This equipment can quickly process holes that meet design requirements and affix labels for easy assembly and installation of the stairs.

Wooden Toys and Small Parts Processing

In the processing of wooden toys and small parts, this equipment can meet the needs of high-precision, multi-batch production.

- Fine hole processing: suitable for drilling holes for connecting toy parts and small decorative parts.

- Marking and packaging: The labeling function can mark the product serial number, brand logo or packaging instructions to add value to the product.

- Machine Structure

The machine tool is welded with a thick steel structure. After the quenching process, the mechanical structure of the heavy six-legged structure is designed. The overall rigidity is strong, the base is solid, and the machine runs smoothly. It can ensure long-term high-speed operation without deformation and no jitter. - Gantry Structure

The gantry column structure is used for stable operation, and all parts of the machine have been manufactured with high precision and assembled to ensure high precision, high performance, and excellent quality. - Transmission structure

The X, Y direction machine adopts double-row imported linear square guide rails, which is stable in operation and high in precision. The four rows of heights are matched with the ball slides. The force is even, the operation is smooth, the noise is small and the service life is long. The imported ball screw is used in the direction B, and the transmission precision is high. , the effect is better. - Working table structure

The imported black ABS plastic plate adopts high-quality features such as high hardness and long-term use without deformation. The countertop opens up a number of dense vacuum adsorption tanks and adsorption hole structure designs and is equipped with a high-power vacuum pump to open an independent six-zone vacuum adsorption area. In the actual operation, each adsorption zone can be separately controlled to ensure the material opening of the plate, and the large plate and small plate cutting adsorption force is firm and various shapes, irregular shapes, and good adsorption effects.

Do you need a catalogue, price or machine working video?

Please let us know your name and email, we will send you more information asap

Be the first to review “Automatic Labeling CNC Drilling and Cutting Furniture Machine”

You must be logged in to post a review.

Reviews

There are no reviews yet.