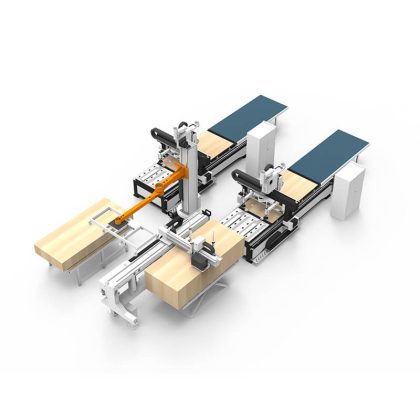

Two CNC Nest Wood Cutting Machine Production Line

Item No:iGC-RL-1T2

This nesting cell consists of a high-speed automatic labeling machine, two automatic loading and unloading ATC nesting CNC machines, a power drum line, and a central control system. Operators only need to put the wooden boards on the lifting platform. Then the labeling machine will automatically label the board, and then the central control system will automatically assign it to the nesting center to for cutting.

Price Range: $50000-$60000

Category: Furniture Making Machine

Description

Labeling and Nesting Cell for Panel Furniture Automatic Production Line

In modern furniture manufacturing, efficiency and precision are paramount. Two CNC nesting wood cutting machines working in tandem can transform your production line, dramatically increasing output while maintaining exceptional quality.

Nesting CNC machine cell furniture cutting production line is composed of multiple CNC nesting machines and multi-axis robots. And it can be flexibly matched and combined according to the customer’s site and output. Therefore, it can effectively reduce human production errors and plate losses. Moreover, it greatly improves the production efficiency and utilization rate of panels.

The lift below the elevated labeler can hold 60 sheets.→The central control software sends the label information to the labeling machine.→After the automatic labeling machine has finished labeling, the robot will distribute it to the No. 1 and No. 2 cutting machines.→The processing program is sent by the central control software to the corresponding cutting machine for cutting. →If the cutting machine has not completed its work, the robot will place the grabbed sheet in the labeling buffer area, and the labeling machine will continue labeling until all processed sheets are completed.

A CNC (Computer Numerical Control) nesting machine is an automated wood cutting system that optimizes material usage by arranging cutting patterns to minimize waste. These sophisticated machines use advanced software to calculate the most efficient layout of furniture parts on sheet materials like plywood, MDF, and particleboard.

This furniture product lines is IGOLDEN 2025 newly designed One-to-Two function machine line: Smart 3.0Pro, it can be meet the demands of modern furniture manufacturing and are ideal for producing precision furniture, suitable for small and medium-sized factories. It can support cutting, engraving, drilling ,milling and labeling, which providing a versatile solutions to meet a wide range of production requirements. All of our CNC router furniture production lines are integrated with the market’s leading CAD/CAM software, streamlining the design-to-production process for increased productivity.

Equipment parameters

| Model | iGC-GL-1T2 |

| Robot | |

| Number of axes | 2-axis |

| Beam length | 10.2m |

| Number of suction cups | 8 |

| Suction cup load weight | Max. 100kg |

| CNC cutting machine | |

| Working area(X,Y,Z) | 1300*2500*250mm(Customizable) |

| Max. empty line speed | 60000mm/min |

| Max. operating speed | 30000mm/min |

| Spindle power | 9.0kw Air-cooled tool-changing spindle |

| Spindle speed | 24000rpm |

| Positioning accuracy | 0.03mm |

| X,Y axis transmission | Rack |

| Z-axis drive | Ball Screw |

| Repeat positioning accuracy | 0.02mm |

| Command language | G Code |

| Operating voltage | AC220V/380V, 50Hz |

Main Configuration

| Name | Details | |

| Ⅰ | Mechanical part | |

| 1 | Bed | Square tube welding structure |

| 2 | Dragon Gate | Steel Structure |

| 3 | Spindle | HQD 9.0kw air-cooled automatic tool-changing spindle |

| 4 | Mesa | PVC vacuum adsorption table |

| 5 | Guide | Taiwan Hiwin |

| 6 | Rack | Taiwan YYC |

| 7 | Lead Screw | Taiwan TBI |

| Ⅱ | Circuit part | |

| 1 | Drive | Dongling Motor |

| 2 | Reducer | SHIMPO |

| 3 | Frequency Converter | Fuling |

| 4 | Electrical components | France SCHNEIDER |

| 5 | Three-color light | Yes |

| 6 | Cabinet | IGOLDENCNC |

| Ⅲ | Tool setting part | |

| 1 | Tool magazine | Inline tool change magazine |

| 2 | Tool setting probe | Automatic tool setting instrument |

| Ⅳ | Oil circuit | |

| 1 | Lubrication system | Automatic oil filling |

| Ⅴ | System Control and Software | |

| 1 | Intelligent connection control system | IGOLDENCNC |

| 2 | Labeling | Automatic labeling |

Applications of the CNC Router Furniture Production Line

CNC router furniture production lines are widely used in the furniture manufacturing industry. Thanks to their excellent compatibility and high degree of automation, they can meet the production needs of a wide range of furniture. They are ideal for modern furniture manufacturers who want to optimize existing production processes and improve product quality. Typical applications of this production line are as follows:

1. Customized and Modular Furniture Production

CNC router furniture production line are good at customized furniture and modular designs. They can perform high-precision cutting and processing to ensure accurate dimensions and beautiful designs, and can meet the needs of personalized customization. They provide strong support for the high-end furniture market.

2. Cabinet, Kitchen Furniture and Wardrobe Production

Whether it is modern cabinets, kitchen furniture or large-capacity wardrobes, the CNC router can achieve high-precision processing, ensuring that the dimensions of each part are the same and the machined surface is smooth and flat, thereby improving the overall assembly quality and aesthetics of the product.

3. Panel Door and Decorative Woodworking Processing

CNC router furniture production line have unique advantages in the processing of panel doors and decorative wood products, and are especially suitable for creating complex carved designs and fine textured decorations. Whether it is a practical door panel or an artistic wood product, precise processing can be achieved.

4. Office Furniture Manufacturing

In the field of office furniture, CNC router furniture production line can quickly, stably and mass produce furniture such as desks and filing cabinets, while ensuring the structural durability and appearance consistency of the products, providing cost-effective solutions for the enterprise market.

Benefits of a Two-Machine Production Line

Enhanced Production Capacity

Running two CNC nesting machines simultaneously can double your production capacity without doubling your floor space requirements. This configuration allows manufacturers to:

- Process multiple orders concurrently

- Reduce lead times significantly

- Meet high-volume demands efficiently

- Maintain continuous production during maintenance cycles

Operational Flexibility

A dual-machine setup provides unprecedented flexibility in furniture manufacturing. While one machine handles large cabinet panels, the second can process smaller decorative components or intricate designs. This parallel processing capability ensures optimal resource utilization throughout your production day.

Minimized Downtime

When operating two machines, you maintain production continuity even during routine maintenance or tooling changes. This redundancy is crucial for meeting tight deadlines and maintaining consistent delivery schedules.

Let’s discuss more to confirm your offer

Do you plan enlarge your current factory or build new factory?

How many square meters does your factory cover? Could you please provide layout of factory?

How much capital budget do you plan to invest in this production line? We have different configuration options to choose from?

What are your requirements for the capacity of this production line?

How many workers do you plan to put into this factory?Whether to hire professional technicians

Do you invest in this project to expand the existing old factory, or is it the first time to invest in the furniture field to build a new factory ?

Equipment Explanation

Automatic Tool Changing

Advanced CNC nesting machines feature automatic tool changers (ATC) with multiple tool positions, enabling seamless transitions between drilling, routing, and cutting operations without manual intervention.

Vacuum Hold-Down Systems

Industrial-grade vacuum tables secure materials firmly during cutting, ensuring precision and preventing material movement that could compromise cut quality.

Dust Collection Integration

Integrated dust collection systems maintain a clean working environment and protect machine components from wood particle accumulation, extending equipment lifespan.

Label Printing Capability

Many modern systems include automatic labeling functions that print identification codes directly onto cut parts, streamlining assembly processes and reducing errors.

The heightened labeling machine is equipped with an intelligent lifting storage platform, which supports the continuous buffer supply of 60 sheets of plate materials, breaking through the traditional single-time loading limitation. The circulating supply mechanism realizes uninterrupted feeding, effectively eliminating the idling waiting time of the equipment, making the labeling unit seamlessly connected with the subsequent process, and improving the overall production line efficiency by more than 40%.

A four-axis robot is used to load materials and transport plates. It cooperates with two CNC cutting machines to grab, position and transport plates. It is characterized by flexible movement and small footprint, which is suitable for small and medium-sized workshop layouts.

The two cutting machines work simultaneously, using professional cutting software, which can design and optimize the layout and positioning of the panels online, thus improving the utilization rate of the panels. Combined with the automatic unloading platform,the processing speed and efficiency are effectively improved.

Related Products

Conclusion

The One to Two CNC Router Furniture Production Line offers a comprehensive solution for manufacturers seeking to improve their efficiency, quality, and flexibility in furniture production. By incorporating advanced CNC technology and customizable configurations, this production line meets the diverse needs of the furniture industry, enabling manufacturers to scale their operations and stay competitive in an ever-evolving market. For more details or to arrange a demonstration, manufacturers are encouraged to contact suppliers or manufacturers specializing in CNC technology.

Do you need a catalogue, price or machine working video?

Please let us know your name and email, we will send you more information asap

Be the first to review “Two CNC Nest Wood Cutting Machine Production Line”

You must be logged in to post a review.

Reviews

There are no reviews yet.