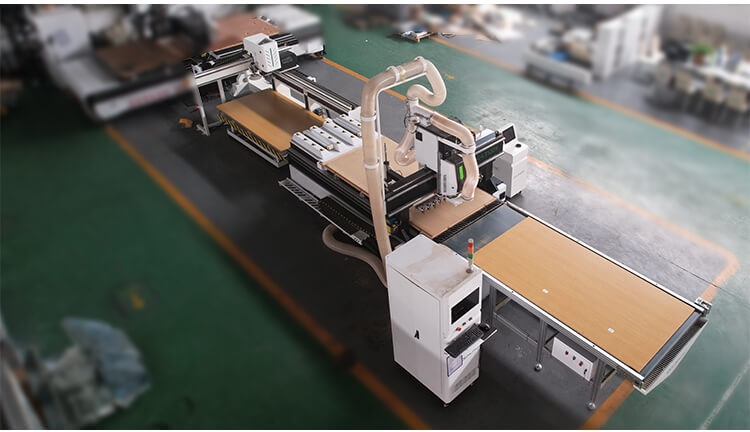

PVC Furniture Making Production Line

iGoldenCNC has established itself as a leading manufacturer of specialized CNC machinery for PVC furniture production, offering comprehensive solutions that cater to the growing demand for affordable, durable, and versatile plastic furniture. Their PVC furniture making production lines are designed to handle the unique requirements of processing PVC materials while maintaining precision, efficiency, and cost-effectiveness.

What Is a PVC Furniture Making Production Line?

A PVC furniture production line is a coordinated sequence of machines and processes that converts PVC materials (notably PVC foam board, PVC sheets, and profiles) into finished furniture components or complete pieces. The line typically includes sheet processing, edge finishing, drilling and routing, assembly, and optional finishing steps, all integrated to maximize throughput and consistency.

Key capabilities you’ll often see:

- Cutting, routing, drilling, and pocketing on PVC panels

- Edge banding and edging to conceal raw edges

- Panel lamination, coating, or veneer alternatives

- Assembly, fastener insertion, and hardware mounting

- Finishing, painting or coating (where required)

- Drying, curing, or weatherproofing for outdoor applications

Function introduction of furniture making production line

- Multi-dimension integration: perfect combination of automatic feeding, optimized cutting, drilling, grooving and automatic cutting. The process is uninterrupted, achieving high efficiency and output, and strong compatibility with a variety of order removal software Seamless;

- Adopt modular design: single spindle CNC drilling package, dual spindle CNC drilling package, three spindles, disc tool magazine automatic tool change spindle, disc tool magazine automatic tool change spindle CNC drilling package five kinds of modular units;

- High-precision processing: cnc router Production Line for Cabinet Furniture 200×250 thick-walled rectangular tube T-shaped structure, tempering or vibration vector effect processing, imported pentahedral metal processing center for high-precision milling processing;

- Guide rail design: side-mounted, three-sided flange slider design structure, stable operation, rack rail guide is all dust-proof design structure, guide rail adopts segmented structure, guide rail replacement without professionals, more convenient;

- Simple operation: imported CNC system, stable performance, simple operation Ordinary people can complete the operation after simple training, without professional knowledge;

- Strengthen the adsorption table: it can adsorb different sizes of plates, and the small cutting plate can reach 25mm;

- Positioning: A four-direction, six-action plate automatic positioning system is adopted. The plate positioning is faster and more accurate. It matches the automatic detection system for plate feeding in place, which can effectively prevent various unexpected situations that may occur during the plate feeding process

- Automatic dust removal: The patented design structure of the whole machine is equipped with a unique feeding and dust removal mechanism, which can completely solve the problem of “dust” in the feeding belt, and can truly achieve continuous work without human intervention;

- Central intelligent management: matching with the central intelligent dust removal system,Production Line for Cabinet Furniture can ensure that the particulate wastes in all links and parts are effectively cleaned and collected, and can effectively guarantee the continuity of the opening work. It is equipped with a central automatic lubrication system and set to automatically Oil injection to ensure the efficient operation of the machine;

Main features of furniture making production line :

- Machine with integral welding body, high inflexibility structure design, material stress analysis & forming by heat treatment, avoid deformation.

- Original Taiwan Syntech controlling system orTaiwan LNC control panel, professional electronic parts, perfect function.

- High accuracy mould working spindle motor with auto tool change function cooling by water or air cooling9kw ATC spindle ,China HQD or Italy HSD.

- Original Taiwan made tool magazine with linear type 8/10/12 pcs of tools.

- Original Taiwan Delta 750w servo driver board and servo motor, Z axis with brake motor.

- All axis with PMI or Hiwin linear rail from Taiwan, high precision imported ball screw transmitting for X, Y, Z axis, also block with self-lubrication function ensure machine running smoothly in high speed, lower noise.

- Industrialized machine frame.

- Standard with vacuum suction table.bigger power vacuum pump, germany brand is optional.

- Standard with vacuum suction table.bigger power vacuum pump, germany brand is optional.

Furniture making production line Working Sample

1.Furniture wooden doors cabinets plate office and wood furniture table,chair door and windows.

2.The wood products voice,game cabinets,computer table sewing machine table,instrument.

3.Plate processing insulation part, plastic chemical components ,PCB inner body of the car, bowling tracks.stair epoxy resin,ABS,PP.PE and the other carbon mixed compound.

4.Decorate industry, Acrylic PVC,MDF,Artificial stone,organic glass,plastic and soft metal.Such as copper,aluminum plate engraving and milling process.

iGoldenCNC PVC Furniture Machine Specifications

Core Machine Features

High-Performance Spindle Systems

- Power Range: 4.5kW to 9kW air-cooled spindles

- Speed Range: 0-24,000 RPM with variable speed control

- Cooling System: Advanced air cooling with temperature monitoring

- Tool Compatibility: ER25/ER32 collet systems for versatile tooling options

Precision Control Systems

- Control System: Syntec/Weihong/NK105 industrial controllers

- Positioning Accuracy: ±0.05mm repeatability

- Drive System: Japanese Yaskawa servo motors and drivers

- Linear Guides: Taiwan Hiwin precision linear guide rails

Robust Machine Construction

- Frame: Heavy-duty steel welded frame with stress relief treatment

- Working Surface: T-slot aluminum table with vacuum hold-down system

- Gantry Design: Moving gantry configuration for optimal rigidity

- Dust Collection: Integrated dust extraction ports throughout

Machine Size Options

Standard PVC Furniture Production Sizes:

- 1325 Model: 1300×2500×200mm working area

- 1530 Model: 1500×3000×200mm working area

- 2030 Model: 2000×3000×200mm working area

- 2040 Model: 2000×4000×200mm working area

Custom Configurations Available:

- Extended Z-axis travel for thick PVC panels

- Multi-head configurations for increased productivity

- Automatic tool changing systems (ATC) with 8-12 tool capacity

- Rotary axis integration for cylindrical components

PVC Material Processing Capabilities

PVC Sheet and Board Processing

Material Thickness Range:

- Thin Sheets: 3-10mm for decorative panels and backing

- Medium Boards: 10-25mm for structural components

- Thick Panels: 25-50mm for heavy-duty furniture parts

- Foam PVC: Specialized processing for lightweight applications

Processing Operations:

- Cutting and Trimming: Clean edge cutting with minimal melting

- Routing and Profiling: Complex edge profiles and decorative features

- Drilling and Boring: Precise holes for hardware and assembly

- Engraving and Texturing: Surface decoration and non-slip textures

PVC Pipe and Profile Processing

Pipe Diameter Capabilities:

- Small Diameter: 20-50mm for chair frames and supports

- Medium Diameter: 50-100mm for table legs and structural elements

- Large Diameter: 100-200mm for heavy-duty applications

Profile Processing:

- Standard Profiles: Square, rectangular, and round tubing

- Custom Profiles: Specialized shapes for specific furniture designs

- Notching and Coping: Joint preparation for assembly

- End Finishing: Clean cuts and chamfering for professional appearance

Production Line Configurations

Basic PVC Furniture Production Setup

Single Machine Configuration ($25,000 – $40,000):

- 1325 or 1530 CNC router with vacuum table

- Basic dust collection system

- Standard software package

- Manual material handling

- Suitable for: Small workshops, prototype development

Standard Production Line ($60,000 – $100,000):

- 2030 CNC router with automatic tool changer

- Pneumatic loading/unloading system

- Advanced dust collection with filtration

- CAD/CAM software suite

- Suitable for: Medium-scale production, custom furniture

Automated Production System ($150,000 – $300,000):

- Multiple CNC routers with integrated workflow

- Robotic material handling systems

- Automated quality inspection

- Production management software

- Suitable for: High-volume manufacturing

Specialized PVC Furniture Applications

Office Furniture Production:

- Desk Components: Tops, panels, cable management systems

- Chair Parts: Seats, backs, armrests with ergonomic shaping

- Storage Solutions: Shelving, filing cabinet components

- Partition Systems: Modular office divider panels

Outdoor Furniture Manufacturing:

- Garden Furniture: Weather-resistant chairs, tables, benches

- Pool Furniture: Chemical-resistant loungers and accessories

- Commercial Seating: Public space furniture with durability focus

- Playground Equipment: Safe, colorful children’s furniture

Healthcare and Laboratory Furniture:

- Laboratory Benches: Chemical-resistant work surfaces

- Medical Furniture: Easy-to-clean patient room furniture

- Cleanroom Applications: Contamination-resistant components

- Storage Cabinets: Pharmaceutical and medical supply storage

Advantages of iGoldenCNC PVC Processing

Material-Specific Benefits

PVC Processing Optimization:

- Temperature Control: Prevents material melting during cutting

- Chip Evacuation: Efficient removal of PVC chips and debris

- Edge Quality: Clean, smooth cuts requiring minimal finishing

- Tool Life: Optimized cutting parameters extend tool life

Chemical Resistance:

- Corrosion Protection: Machine components resistant to PVC additives

- Easy Cleaning: Smooth surfaces prevent material buildup

- Ventilation Systems: Proper extraction of processing fumes

- Safety Features: Protection from PVC dust and particles

Production Efficiency Advantages

High-Speed Processing:

- Rapid Traverse: 25-35m/min rapid positioning speeds

- Optimized Cutting: 8-15m/min cutting speeds for PVC

- Reduced Cycle Time: Efficient toolpaths and machine acceleration

- Batch Processing: Nesting software for material optimization

Consistent Quality:

- Dimensional Accuracy: Tight tolerances for assembly fit

- Repeatability: Identical parts across production runs

- Surface Finish: Consistent quality requiring minimal post-processing

- Quality Control: Integrated measurement and inspection capabilities

Software and Programming Solutions

CAD/CAM Integration

Design Software Compatibility:

- Native Support: Works with AutoCAD, SolidWorks, Rhino

- Industry Software: Specialized furniture design programs

- File Formats: DXF, DWG, STEP, IGES compatibility

- 3D Modeling: Support for complex curved surfaces

Programming Features:

- Automatic Toolpath Generation: Optimized cutting strategies

- Nesting Algorithms: Maximum material utilization

- Tool Management: Automatic tool selection and compensation

- Simulation: 3D visualization before cutting

Production Management

Workflow Control:

- Job Scheduling: Production planning and sequencing

- Material Tracking: Inventory management and usage reporting

- Quality Monitoring: Statistical process control integration

- Maintenance Scheduling: Preventive maintenance alerts

Cost Analysis Tools:

- Material Costing: Accurate cost calculation per part

- Time Studies: Production time analysis and optimization

- Efficiency Metrics: Overall equipment effectiveness tracking

- Profitability Analysis: Job and product line profitability

Market Applications and Industries

Commercial Furniture Manufacturing

Office Furniture Market:

- Market Size: $14.2 billion globally

- Growth Rate: 5.1% CAGR through 2028

- Key Drivers: Remote work trends, office redesign needs

- PVC Advantages: Cost-effective, customizable, easy maintenance

Healthcare Furniture Sector:

- Market Demand: Infection control and easy cleaning requirements

- Regulatory Compliance: FDA and healthcare standards compatibility

- Durability Requirements: High-use environment resistance

- Cost Pressures: Budget-conscious healthcare systems

Residential and Consumer Markets

Outdoor Living Furniture:

- Market Growth: 6.8% CAGR driven by home improvement trends

- Weather Resistance: PVC’s natural outdoor durability advantages

- Color Options: Wide range of aesthetic possibilities

- Maintenance-Free: Consumer preference for low-maintenance products

Children’s Furniture:

- Safety Standards: Non-toxic, rounded edge capabilities

- Easy Cleaning: Important for children’s environments

- Bright Colors: PVC’s color retention and variety

- Durability: Resistance to impacts and abuse

Cost Analysis and ROI Considerations

Investment Breakdown

Equipment Costs:

- Basic Machine: $25,000 – $45,000

- Software: $2,000 – $8,000

- Tooling: $3,000 – $8,000

- Installation: $2,000 – $5,000

- Training: $1,000 – $3,000

Operating Costs (Monthly):

- Utilities: $300 – $800

- Consumables: $500 – $1,500

- Maintenance: $200 – $600

- Labor: $3,000 – $8,000

- Facility: $1,000 – $3,000

Revenue Potential

Production Capacity:

- Single Shift: 40-60 parts per day

- Double Shift: 80-120 parts per day

- Part Values: $15 – $150 per component

- Monthly Revenue: $15,000 – $50,000+ potential

Payback Analysis:

- Typical Payback: 12-24 months

- Factors: Production volume, part complexity, market pricing

- ROI: 25-50% annual return on investment

- Growth Potential: Scalable with market demand

Quality Control and Standards

Manufacturing Standards

Dimensional Tolerance:

- Standard Tolerance: ±0.1mm for most applications

- Precision Work: ±0.05mm for critical fits

- Surface Finish: Ra 1.6μm typical surface quality

- Edge Quality: Clean cuts requiring minimal finishing

Material Compliance:

- Food Grade: FDA-approved PVC processing capabilities

- Fire Retardant: UL-rated material processing

- Environmental: RoHS and REACH compliance

- Recycling: Support for recycled PVC materials

Inspection and Testing

Quality Assurance Systems:

- In-Process Monitoring: Real-time quality feedback

- Statistical Control: SPC implementation capabilities

- Documentation: Complete traceability and record keeping

- Certification: ISO 9001 quality management support

Leave a Reply

You must be logged in to post a comment.