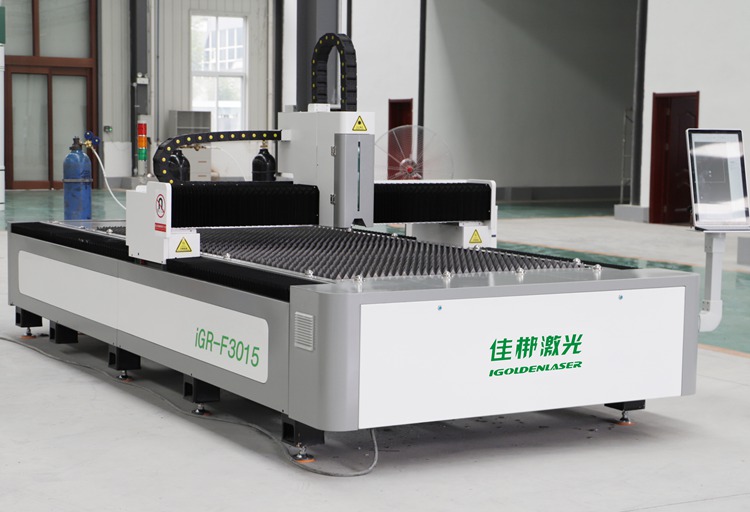

1000w Fiber Laser Cutting Machine for Metal

A 1000W fiber laser cutting machine is a high-precision, computer-controlled cutting system that uses a powerful 1000W fiber laser to cut a wide range of materials, including metals like stainless steel, carbon steel, aluminum, and brass. These machines are widely used in industries such as manufacturing, automotive, aerospace, and metal fabrication due to their efficiency, precision, and cost-effectiveness.

1000w Fiber Laser Cutting Machine

1 kw laser cutting machine deliver maximum cutting speeds with high accuracy and repeat ability boosting productivity to maximum levels. The fiber laser offers significantly faster processing speeds thanks to astonishing acceleration rates of linear drives and higher power resonators. These are significant advantages for thinner sheet metal cutting as production rates can double or even triple while operating costs decrease by up to 50%.

Applications of a 1000W Fiber Laser Cutting Machine

- Metal Fabrication:

- Cutting sheet metals for manufacturing components.

- Automotive Industry:

- Producing car parts, panels, and structural components.

- Aerospace Industry:

- Precision cutting of lightweight and durable components.

- Signage and Advertising:

- Engraving and cutting designs for metal signs and logos.

- Electronics:

- Creating precise parts for electronic devices and enclosures.

- Construction:

- Cutting structural metal components for building projects.

- Jewelry Design:

- Producing intricate patterns and designs on metal jewelry.

Advantages of laser cutting services:

Laser cutting machines are highly efficient and design replicas are the exact copies of each other.

It requires and consumes less amount of energy to cut sheets of all types of materials.

In comparison with the traditional scissors, laser cutting machines take less time to cut large sheets and the outcome is extremely accurate.

The entire process is monitored by the computer programs which reduce the amount of work and workload.

Much human intervention is not required except for maintenance and observation. No danger of accidents or injuries

Very flexible, can be used to cut almost all types of materials.

Precise cuts can be obtained within short time.

Applications of Fiber Laser Cutting System

Laser metal cutting machine is widely used in hardware, precise machinery, automobile components, glasses clocks and watches, precisioncutting, medical equipment, instrument and other metal related industry. It can carry on non-contact cutting on metal sheet, pipe, especially for stainless steel, steel plate, diamond saw blades and other metal materials, it has excellent processing for the various high-brittle hard alloys. In the lines of hardware and metal sheet industries, 1 kw laser cutting machine technology can be partially replace the line cutting.

Customer feedback for fiber laser cutting and plasma cutting machines

1. The surface of the plasma cutting machine is rough, it has advantages in cutting thick plates, and the price is low.

2. The cutting surface of 1 kw laser cutting machine is smooth, and the plasma is rough, so it is necessary to send someone to repair the burr. The laser cutting surface is smooth, the compensation precision is relatively high, and it is a little more expensive.

3. The disadvantage of plasma is that the cutting slit is wide, it is about 3MM. The most important part of the plasma is the power supply, which is equivalent to the laser souce of the laser cutting machine. The power consumption of the plasma is quite severe. The commonly used spare parts electrode protection nozzles are also expensive, especially the electrode often need to be replaced.

4. Plasma is often used for thick plate cutting, while fiber laser cutting machine is often used for thin plate cutting. Plasma cutting needs to send someone to trim burrs, while laser cutting can be formed at one time. No secondary processing is required.

Considerations When Buying a 1000W Fiber Laser Cutting Machine

- Material Thickness Requirements:

- Ensure the machine can handle the maximum thicknesses of materials you plan to cut.

- Worktable Size:

- Choose a machine with a cutting bed size suitable for your projects.

- Laser Source Quality:

- Look for reputable brands like IPG, Raycus, or nLIGHT for reliable laser sources.

- Automation Features:

- Features like auto-focus, material detection, and CNC programming enhance productivity.

- Cooling System:

- Ensure the machine has an efficient cooling system (usually water-cooled) to avoid overheating.

- Safety Features:

- Verify the presence of safety enclosures, alarms, and dust collection systems.

- After-Sales Support:

- Choose a manufacturer that offers technical support, training, and a warranty.

Conclusion

A 1000W fiber laser cutting machine is a versatile and efficient tool for cutting thin to medium-thickness metals with precision and speed. It is an excellent investment for businesses in metal fabrication, manufacturing, and other industries requiring high-quality cutting. By choosing the right machine and features, you can significantly improve productivity, reduce costs, and achieve superior results.

Leave a Reply

You must be logged in to post a comment.