CNC Wood Drilling Machine

Item No.: CNC Drilling Machine

A CNC wood drilling machine is a precision tool designed to automate drilling, routing, and sometimes milling operations on wood, MDF, plywood, and similar materials. It’s ideal for furniture production, cabinet making, and woodworking projects that need repeated accuracy.

If you need more detailed information, please inform us as soon as possible.

Description

CNC Drilling Machine Wood

A wood drilling machine is a general term for machinery and equipment that uses a harder and sharper drill bit to leave cylindrical holes or square holes in the processed material by using means of rotary cutting or rotary extrusion. It is also known as wood hole machine, wood boring machine, drill machine wood cutter, wood carving drill machine, carpenter drill machine, woodworking drillers, woodworking punching machines, woodworking drilling machines, and woodworking through-hole machines.

This wooden hole machine is mainly used to solve the problem that the CNC discharging machine cannot punch or bore side holes, and the accuracy of ordinary pneumatic drills is not high. In addition, it is rid of repeated positioning. Wood drilling machines have two types: semi-automatic wood drilling machines and fully automatic wood drilling machines. With the development of society, the drilling technology of automatic drilling machines has improved, and the application has become more extensive.

How Many Wood Drilling Machine Types?

Actually, wood drilling machines can be divided into many kinds. The wood drilling effect and woodworking drilling efficiency achieved by different wood drilling machines are very different. In addition, a wood drilling machine can customize the number of drill bits according to customer needs. IGOLDEN can provide you with a single head hinge wood drilling machine, double-head side wood boring machine, multi-head boring machine for wood, and automatic six side CNC wood drilling machine.

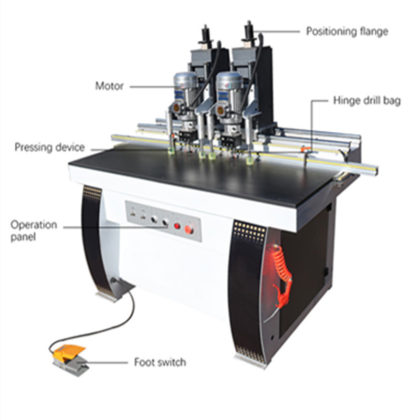

Hinge wood drilling machine

It is a kind of desktop wood drilling machine with two boring heads. Besides, it is also the ideal equipment for cabinet, wardrobe, and door processing manufacturers. This machine is a kind of vertical wood drilling machine, which drills holes up and down. IGOLDEN mainly provides hinge woodworking hole machines with single or double heads. The wood drilling machine with two heads is more upgraded than the single-head drilling machine. Furthermore, its drilling efficiency is twice that of the single one.

This hinge wood driller can also adjust the drilling position vertically and horizontally, which is convenient and quick to adapt to the requirements of drilling processing. It adopts the design of a drill bag, which has the characteristics of low noise and good durability. Besides, it is equipped with a positioning baffle and precise scale, and the baffle can be adjusted according to work needs. It adopts foot switch control, which is labor-saving, simple, fast, and has a long service life. At the same time, it also has a wide range of uses, and one machine can match many different drill bits.

Side wood drilling machine

Compare to the single head hinge wood boring machine and wood drilling machine with one head, the double head side hole drilling machine can work on two different wooden pieces at the same time. Therefore, this two-in-one side drilling machine is more efficient and faster to drill holes on the wood boards.

In addition, what is different from the double-head hinge drilling machine is the drilling method. The double head wood drilling machine is good at moving left and right to punch holes, while the hinge drilling machine usually bores holes up and down on the surface of wood panels.

Multi-head wood drilling machine

This wood hole machine is often designed with more than three drilling heads. When you want to use it for boring holes, first, start the machine and let it back to the starting position. And then, set parameters on the control panel. Next, scan QR code on the board surface to drill. Besides, it can also help you complete wood board grooving. Moreover, three work stations can work continuously to improve efficiency. And laser scanning is better for accurate positioning.

In addition, this multi-head side hole machine for wood adopts an open workbench interface and supports various docking furniture design and production software. It can realize blindly play because of the simple operation. Furthermore, without any software, it can realize intelligent production.

Six-side CNC wood drilling machining center

A six-side wood drilling machine is a very high-end machine for customizing horizontal punching board furniture. It is a piece of power wood drilling machine for large industries. This professional wood hole drilling machine has the advantages of high processing accuracy and fast speed. It is a piece of fully automatic drilling equipment, completely replacing the traditional drill bit, and getting rid of the traditional punching mode.

This machine has 12+8 upper drills and 9 lower vertical drills, one-time positioning can realize four-sided drilling and double-sided grooving of the workpiece. With a movable worktable, it can move smoothly left and right, which is convenient for the accurate processing of workpieces. Its processing power can reach 2.2kw, and its processing thickness can reach 40mm. In addition, it can also process boards of different sizes, such as 600*50mm small boards, 270*600mm medium boards, and 600*900mm large boards. Furthermore, it also has the function of upgrading the board directly to realize the rear discharge.

The six-side CNC wood hole machine is an indispensable equipment for custom panel furniture production. Especially for those small and medium-sized custom furniture manufacturers who want to increase output, CNC six-sided wood drilling equipment is definitely your best choice. Compared with the punching effect achieved by the CNC nesting machine and the side hole drilling machine, the six-sided drilling machine not only saves effort, but also has advantages in processing accuracy and processing efficiency. Therefore, CNC six-sided drill is an indispensable CNC equipment for custom furniture manufacturers.

CNC nesting machine for wood drilling

The nesting CNC machine is a high-end computer numerical control machine, which can better meet different processing requirements of customers. With multiple spindles, it can work one by one to realize different processing functions. In addition, it can change different tools in 0 seconds, such as cutting, engraving, grooving, and drilling woods. Besides, it also uses the loading and unloading platform to quickly and automatically load and unload materials. And the positioning cylinder can ensure better position precision.

ATC CNC router with drilling head

We provides you with an ATC CNC wood drilling machine with customized sizes, such as a 2060 carousel ATC CNC router for wood boring and a 1325 linear ATC CNC machine for boring wood. This ATC CNC router with a CNC drilling head is good at wood drilling and cutting. The drilling head is equipped with 9 vertical and 3 horizontal drill bits, which can realize side boring and vertical drilling. It makes the drilling and cutting process more efficient and saves labor. This is the best machine combination for furniture, cabinet, and door making.

CNC Drilling Machine Application:

1. Furniture Making:cabinet doors, wooden doors, solid woods, plates, antique furniture, wood windows, wooden desks, and wood chairs.

2. Decoration:screens, wave boards, large-size wall hangings, advertising boards, and signs.

3. Processing Materials:drilling for acrylic, PVC, MDF boards, artificial stones, organic glass, plastics, stones, woods, bamboos, marbles, organic boards, double-color boards, and soft metal sheets such as copper and aluminum.

Why Choose CNC Drilling for Woodworking?

Unmatched Precision: CNC drilling machines achieve accuracy within 0.01mm, ensuring that dowel holes align perfectly, hardware mounts precisely, and assembly becomes effortless. This level of precision is virtually impossible to achieve consistently with handheld tools.

Time Efficiency: What might take hours with traditional methods can be completed in minutes with CNC drilling. The machine works tirelessly, drilling multiple holes simultaneously or in rapid succession, dramatically increasing your productivity.

Complex Pattern Capability: Create intricate hole patterns for decorative panels, precise grid layouts for shelving systems, or complicated joinery patterns that would be extremely challenging manually. The machine executes your digital design exactly as specified.

Repeatability: Once you’ve programmed a drilling pattern, you can reproduce it perfectly across hundreds of pieces. This consistency is invaluable for furniture production, cabinetry, and any project requiring multiple identical components.

FAQ

Multi-Spindle Configuration: Advanced CNC drilling machines feature multiple drilling heads operating simultaneously, multiplying your output capacity. Some models offer independent control of each spindle for different hole depths and diameters in a single pass.

Automatic Tool Changing: Higher-end machines automatically switch between drill bits of different sizes, eliminating manual intervention and enabling complex drilling sequences without stopping production.

Dust Collection Integration: Efficient dust extraction systems keep your workspace clean and protect the machine’s precision components from wood debris. This feature is essential for maintaining accuracy and extending equipment life.

Work Surface Size: Choose a machine with a work area matching your typical project dimensions. Larger surfaces offer versatility but require more workshop space and investment.

Common manual woodworking drilling presses on the market are relatively cheap, ranging from tens of dollars to hundreds of dollars. Although it is small in size, cheap in price, and simple in operation, it is inconvenient to operate, low in efficiency, simple in processing, and poor in processing results. Therefore, in order to ensure customers a better processing experience, IGOLDENCNC designed and launched a more intelligent CNC wood drilling machine. Prices range from a few hundred to tens of thousands of dollars.

The attached table below is about the prices of several popular drilling machines for wood work from IGOLDEN, for reference only. The specific configuration and price are determined by the actual situation.

| Model | Price |

| Single head hinge drill machine | $400 |

| Double head hinge drill machine | $850 |

| Single-head side drilling machine | $3,200 |

| Double-head side drilling machine | $3,500 |

| Three head side drilling machine | $5,400 |

| Automatic six head CNC drilling machine for wood | $35,000 |

| ATC CNC Router with CNC aggregate head for sale | $16,000-$27,000 |

If you are a novice, it is recommended to buy a hinge drill machine wood cutter, single head wood carving drill machine, and double head carpenter drilling machines. These three models are cheap and quick to get started, and they are also the first choice for beginners.

But if you need to achieve multi-angle drilling or drilling holes in large quantities, then it is recommended that you buy a fully automatic six-sided drilling machine or an ATC CNC machine with an aggregate head or a drill bit. These two CNC woodworking drilling machines are multi-functional in one. The high-end CNC woodworking machine can not only drill holes on all sides of the board, but also realize board cutting and 2D or 3D engraving. You can choose according to your actual budget and processing needs.

An automatic wood drilling machine is also called a CNC woodworking punching machine. It is a piece of economical and practical drilling equipment for panel furniture, as well as a piece of indispensable subsidiary equipment in the panel furniture production line. The wood drilling machine is used for drilling, grooving, and punching, reaming, chamfering, etc. It can not only realize vertical drilling, horizontal drilling, and side drilling of the wooden board, but also make grooves for invisible parts. In addition, it can drill holes at multiple angles and complete five side drilling at the same time.

Woodworking CNC drilling machines have the advantages of high precision, fast speed, high efficiency, good quality, high safety, etc. They are safer, more efficient, and more accurate than hand wood drill machines. It can not only reduce the labor costs and time costs of users, but also greatly improve the customers’ production efficiency. Therefore, it is more and more favored by users at home and abroad, especially for manufacturers of furniture production lines. With it, the drilling production process has been optimized to a large extent. Thus, it is indeed the best choice for drilling holes.

At the same time, it has a wide application in the panel furniture industry, solid wood furniture, solid wood doors, decorative materials, cabinet doors, computer desks, kitchen utensils, cabinets, construction machinery industries, especially for some hardware parts that have multiple holes that need to be processed.

The iGoldenCNC Difference

We provide comprehensive training and ongoing support to ensure you maximize your CNC drilling machine’s potential. Our technical team understands woodworking challenges and offers practical solutions tailored to your specific needs.

Do you need a catalogue, price or machine working video? Please let us know your name and email, we will send you more information asap.

Be the first to review “CNC Wood Drilling Machine”

You must be logged in to post a review.

Reviews

There are no reviews yet.