5 Best Way Laser Engraved Glass

Laser engraving glass is a precise, clean, and elegant way to personalize or decorate glass objects. Whether for industrial use, custom gifts, or art projects, using the right technique ensures the best results.

As we all know, laser etching machine can be used for engraving various materials, but how to use laser to etch fragile materials such as glass, crystal and ceramics is a problem. What laser etcher should be chosen to engrave glassware so as to form beautiful patterns and texts without breaking the glass?

Fiber Laser Glass Cutting Machine

Designed with patented technology, our CNC glass laser cutter is capable of cutting glasses flawlessly. Our cutting machine does not cause much stress on the glass materials. Also, there is no risk of cracks and chips. You will find zero yield loss with the laser-based glass cutter.

High-definition image alignment and professional customized operation software control system make the production efficiency higher, the repeated positioning more accurate, and the operation easier. The equipment has been widely used in instrumentation glass/photovoltaic glass/mobile phone glass/medical instrument/vehicle display/panel display glass and other industries.

CO2 Laser Glass Engraving Machine

The CO2 laser engraving machine uses a CO2 sealed laser tube to etch the glass surface. It can etch on the large-format glass surface. The most common table sizes are 400mm x 600mm, 600mm x 900mm (2′ x 3′), 900mm x 1300mm, 1300mm x 2500mm (4′ x 8′), 1500mm x 3000mm (5′ x 10′), you can choose based on your business needs. Generally, the laser can form frosting or shattering effect on the glass surface. Usually users want to get frosted rather than broken effect, which depends on the texture of the glass and whether the hardness is consistent.

CO2 laser glass engraver costs anywhere from $3,000 to $5,500 based on different configurations.

CO2 laser etched glass projects can be made with a smoother frosted surface if you follow the three steps:

Step 1. Apply a little wash to the area to be etched, find a piece of newspaper or napkin that is slightly larger than the area to be etched, soak the paper completely with water, squeeze the excess water, and place the wet paper on the etching area. Flat without wrinkles.

Step 2. Put the glass in the machine, work while the paper is still wet, then take out the glass, remove the remaining paper, and then clean the glass surface.

Step 3. If desired, lightly polish the glass surface with 3M Scotch-Brite. In general, the laser power should be set lower, the precision should be set at 300dpi, and the engraving speed should be faster. You can try to use large-sized lenses for engraving.

UV Laser Glass Marking Machine

UV laser markers provide clear, long-lasting etching on virtually any color or type of glass bottle, so there are no glass breakage consequences. Ultraviolet laser marking machine is also called cold light laser marking. It adopts ultraviolet laser with wavelength of 355um, which has smaller diameter of focusing spot, more precise marking effect, and high absorption rate of ultraviolet light to engrave on metal or glass materials. UV laser marking on flat glass is directly related to the peak power of the laser, the size of the final focused spot, and the speed of the galvanometer. Ultraviolet laser marking machine has unique and superior performance, which is very suitable for laser etching of glass bottles. It provides greater quality with efficiency, clear, durable coding on virtually any color or type of glass bottle, and is designed for high-quality marking with virtually no font, coding or graphic restrictions.

The UV laser marking machine, with the integrated structure, high precision, high speed, is the best choice for fine marking processing.

Widely used in flexible PCB board marking, marking; Silicon wafer microporous and blind hole processing; LCD glass TWO-DIMENSIONAL code marking, glassware surface punching, metal surface coating marking, plastic keys, electronic components, gifts, communications equipment, construction materials, and so on.

UV laser glass etching machine is priced from $5,400 to $30,000.

CO2 Laser Glass Marking Machine

Compared with ordinary glass etching methods, CO2 laser marking technology has high processing efficiency, fast speed, beautiful and detailed marking products, and does not require material consumption, environmental protection, energy saving, and convenient maintenance. It is the best choice for etching glass products. The disadvantage is that the marking area is up to 300mm x 300mm.

CO2 laser glass markers have a price range from $3,400 to $8,000.

CO2 laser glass marking machine is a laser galvanometer marking machine that uses CO2 gas as the working medium. CO2 and other auxiliary gases are charged into the discharge tube and high voltage is applied to the electrode, and a glow discharge is generated in the discharge tube, so that the gas emits a laser beam with a wavelength of 10.64um, and the laser energy is amplified, with the galvanometer scanning and the F-Theta mirror focusing, the computer will drive the laser marking control card to etch photos, characters, numbers and lines on the glass surface based on the user’s requirements.

Laser Glass Etching Machine

Laser etching machine is to adjust the focus position of the high-energy laser beam, so that the laser directly acts on the film layer to be etched, so that the surface coating is instantly vaporized, so as to achieve the effect of etching, and because of the adjustable nature of the laser energy, it will not affect the bottom substrate during the processing. Compared with chemical reagent etching, this method is smaller in volume, easy to operate, low in cost and high in yield.

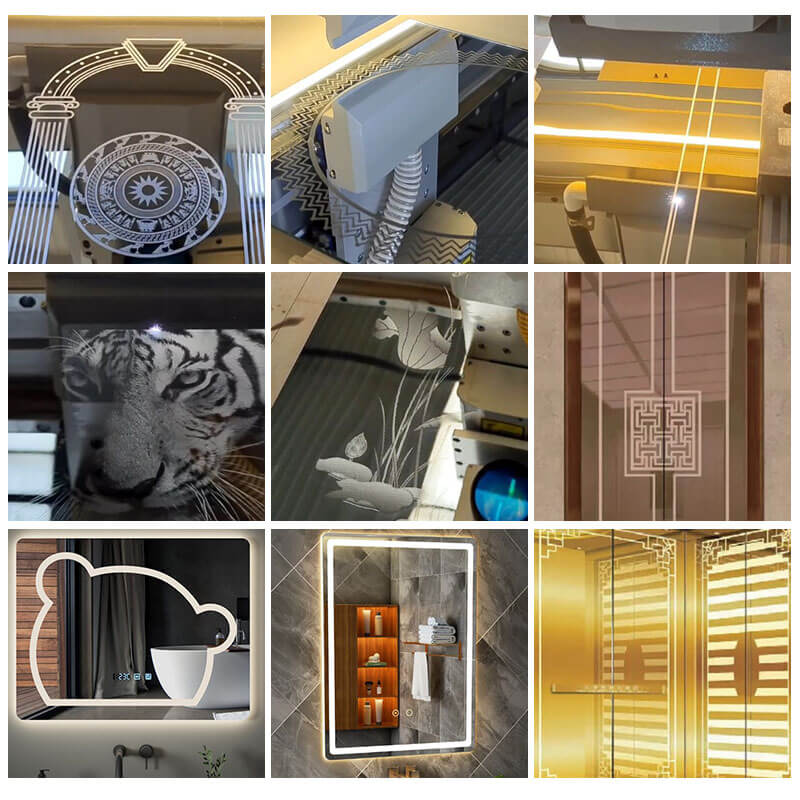

Laser etcher can perform decoration and associated engraving on the surface of glass and mirror materials. The machine is equipped with the latest control technology of the top fiber laser source and enhanced large size flat bed, forming a small spot with strong power on the processing material, and then use the laser energy to form a pattern on the surface of the material, by removing the paint on the mirror, so that the glass is completely transparent, widely used in bathroom mirrors and furniture stained glass manufacturers.

5 Best laser engraved glass

Here are five of the best applications and products for laser-engraved glass, showcasing their versatility and appeal:

1. Personalized Drinkware

Laser engraving on glass mugs, tumblers, and wine glasses allows for custom designs, names, or logos. This makes them perfect for gifts, promotional items, or special occasions like weddings and anniversaries.

2. Awards and Trophies

Glass awards and trophies can be beautifully laser-engraved with intricate designs, names, and achievements. This adds a sophisticated touch to recognition events, making them memorable keepsakes.

3. Decorative Glass Panels

Laser engraving can create stunning designs on glass panels used in home decor. Whether for partitions, wall art, or decorative screens, these panels can feature intricate patterns or personalized imagery.

4. Photo Engravings

Transferring photos onto glass through laser engraving results in unique and sentimental gifts. These can be framed or used as decorative items, ideal for commemorating special moments.

5. Custom Glass Coasters

Laser-engraved glass coasters can feature logos, designs, or quotes, making them great for both personal use and corporate gifts. They add a personal touch to dining experiences and events.

Leave a Reply

You must be logged in to post a comment.