Automatic Cabinet Making CNC Machine – IGOLDENCNC

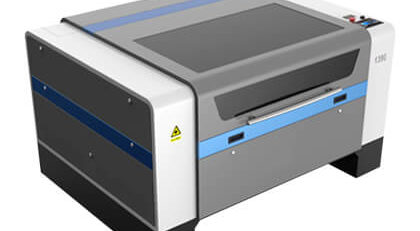

What is Automatic Cabinet Making CNC Machine ?

Automatic Cabinet Making CNC Machine is suitable for kitchen cabinets making, cabinet door making, corner cabinets making, decorative cabinets making, home cabinets making, wall cabinets making, wood cabinets making, base cabinets making and other custom cabinets making in bathroom, garage, living room, office.

Feature of Automatic Cabinet Making Machine

- The four air-cooling spindles of the CNC router for cabinet making can automatic finish the vertical hole drilling, slot cutting, carving in one step.

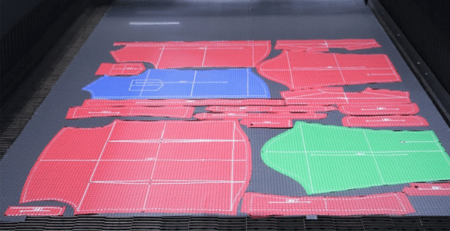

- The CNC router for cabinet making has advantages of saving time, labor and materials, replace traditional CAD draftsmen, splitting men, cutting men, only need 8 minutes to input size design and split. Automatic layout optimization, improve material utilization. High quantity automatic design, Automatic type setting, no human intervention.minimizing error rate to minimum, ensure the quality of the order.

- High efficiency: Double table for cabinet making, when finish one work line, it can auto work on another table, greatly improve the work efficiency.

- Drive Faster: Two motor driving on Y axis, Fast speed, high efficiency, Max Air move speed to 60m/min.

- Operation Steadily: The best linear square guide, double row and four row ball slider, large loading capacity. Convenient operation, high precision, long life time.

- Intelligent control: It adopts the original computer control system, has a break point, power outages, has the function of re-carving after break point and power failure.

- Sturdy Durable: Heavy T type of lathe bed, strong rigidity, big strength, smooth rotation, speed for a long time not deformation, not shake.

- Independently electric control box with perfect wiring and free moving pulleys.

Advantages of Cabinet Making CNC Machine

- Increase 10% material usage.

- Reduce the dependence of the technical workers.

- Decrease of sorting procedure and sorting error.

- Save both time and labour for complicated workpiece processing.

- It can also groove and drill.

- Improve the product quality and the efficiency.

- Optimize technology procedure, reduce the production cost.

Hot Applications Include:

Hot Applications Include:

>Production and processing of various types of furniture: cabinets, wardrobes, office furniture, computer tables, children’s furniture, panel furniture, cutting and cutting, slotting and perforating, decoration hollow frames, soft bag background wall production, etc.;

>Wooden door and furniture decoration industry: solid wood and composite door, cabinet door, large-area plate carving, solid wood, panel furniture carving, solid wood art mural carving, etc .;

>Wood products processing: clocks, sporting goods and equipment;

>Musical instrument industry: three-dimensional curved surface and shape cutting of sculpture musical instruments;

>Crafts industry: photo frames, jewellery boxes.

Leave a Reply

You must be logged in to post a comment.