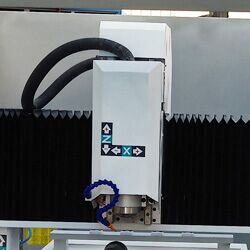

CNC Machine for Wood and Metal

CNC machine stands as a beacon of innovation and precision. Whether working with wood or metal, CNC machines have revolutionized the way we approach crafting, design, and production.

CNC Machine for Wood and Metal

CNC machines for wood and metal are specialized tools that utilize computer-controlled movements to cut, shape, and carve materials with exceptional precision. These machines offer increased efficiency, accuracy, and repeatability, making them an important part of many manufacturing processes. They can be used for a wide range of applications, including machining and shaping parts, prototyping, production, engraving and marking, woodworking, and metalworking.

A CNC router is primarily designed for woodworking but can also handle certain metalworking tasks. It uses a rotating spindle with cutting tools, such as router bits, to carve and shape the material. CNC routers are ideal for intricate designs, 2D and 3D carving, and edge profiling. While they are not typically suited for heavy metal machining, they can work with softer metals like aluminum or brass.

CNC machines with the right tooling and programming can be used to process a variety of materials, including wood, metal, plastics, and composites. This versatility allows manufacturers to utilize a single CNC system for multiple applications, improving efficiency and reducing the need for specialized equipment.

Applications of CNC Machines

- Woodworking: Creating furniture, cabinetry, musical instruments, and decorative items.

- Metalworking: Producing machine parts, automotive components, aerospace parts, and custom metalwork.

Woodworking

In the woodworking industry, CNC machines have become essential tools for creating intricate designs and ensuring consistent quality. They are used for:

- Cabinet Making: CNC routers can cut and shape wood with high precision, making them perfect for custom cabinetry.

- Furniture Design: Complex patterns and designs can be easily replicated.

- Carving and Engraving: Detailed carvings and engravings are achieved with minimal effort.

Metalworking

CNC machines are equally vital in the metalworking industry, where precision and durability are paramount. Applications include:

- Automotive Parts: CNC machines produce parts with exact specifications.

- Aerospace Components: High-precision parts are essential for safety and performance.

- Tool and Die Making: CNC machines create the molds and dies used in manufacturing.

Benefits of Using CNC Machines

Precision and Accuracy

One of the most significant advantages of CNC machines is their ability to produce parts with exceptional precision. This level of accuracy is crucial in industries where even the smallest deviation can lead to significant issues.

Efficiency and Productivity

CNC machines can operate continuously, 24/7, without fatigue. This capability significantly boosts productivity and reduces lead times, making them invaluable in high-demand manufacturing environments.

Versatility

CNC machines are incredibly versatile, capable of working with a wide range of materials, including wood, metal, plastic, and composites. This versatility makes them suitable for various industries and applications.

Cost-Effectiveness

While the initial investment in a CNC machine can be substantial, the long-term benefits, including reduced labor costs and increased efficiency, often outweigh the initial expense.

When choosing a CNC machine for working with both wood and metal, consider the following factors:

- Material compatibility: Ensure that the machine is suitable for the specific types and thicknesses of wood and metal you plan to work with.

- Power and torque: Consider the machine’s power and torque capabilities, as they affect the cutting performance and ability to handle different materials.

- Spindle or tool compatibility: Check if the machine supports various cutting tools, such as different types and sizes of router bits or end mills, for working with both wood and metal.

- Rigidity and stability: Look for a machine that offers a sturdy and rigid construction to handle the forces involved in cutting both wood and metal.

- Software and control system: Evaluate the machine’s control software and compatibility with CAD/CAM programs to ensure smooth operation and ease of programming.

- Safety features: Consider the presence of safety features like emergency stop buttons, protective covers, and safety interlocks to ensure operator safety.

Features of CNC Machine for Wood and Metal

Adopt European standard dustproof structure design.

Dustproof and waterproof, effectively improve the working environment.

Ensure long-term stable and high-precision operation of the machine, improve equipment safety performance.

Leave a Reply

You must be logged in to post a comment.