Leading the Trend of The Times–5 Axis ATC CNC Router Machine

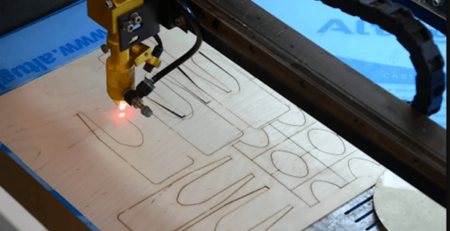

What is 5 Axis ATC Cnc Router Machine?

Advanced 5 Axis CNC Router Machine, also known as 5 axis cnc machining center, 5 axis cnc milling machine, is good at space curved surface processing, special-shaped processing, hollow processing, punching, oblique drilling, etc. It is widely used in aerospace, military scientific research, precision machinery, high-precision medical equipment, normal manufacturing, etc.

Features of 5 Axis ATC Cnc Router Machine:

1.With OSAI numerical control system, the machine is of high speed and high machining accuracy.

2.The Japan THK rails and the Germany original rotating arm ensure the accuracy and strength of the machine.

3.Z-axis travel can be heightened to 2.1 meters, so it is very suitable for processing large-scale three-dimensional surface.

4.The intelligent processing cross-border protection function can prevent the excessive process caused by mechanical collision.

5.Diversified control processing speed can control the working speed, traveling speed and dropping tool speed, and it improves the quality and efficiency greatly.

6.Stand column welded with 12mm and 16mm thick channel steels and square tubes, processed by high temperature tempering and finishing machining.

7.Machine beam welded with 12mm and 14mm thick channel steels and square tubes, middle with two layers stiffeners.

The application of 5 axis cnc machine:

5 axis cnc machine are mainly used for foam mold, wood mold, large plastic mold, large casting mold. Processing and manufacturing of lampshade molds and large special molds.

Woodworking: wooden door and furniture, windows, tables and chairs,cabinets and panels, 3D wave plate,MDF,computer desk,musical instruments,etc.

Advertising: billboard, logo,sign,3D characters cutting,acrylic cutting,LED/neon channel, literal-hole cut,lightbox mold,stamp,mould,etc.

Die industry: copper sculpture,aluminum engrave,metal molds,plastic sheeting,PVC ,etc.

Decoration: acrylic, density board, artificial stone, organic glass, soft metals like aluminum and copper, etc.

The Benefits of 5-Axis CNC Machining

With 5-axis machining, you have the ability to machine complicated shapes with a single setup, which improves efficiency, saves time, reduces costs, and prevents operator error. … Complex Parts: This process allows you to machine complex parts that would otherwise require casting.

Leave a Reply

You must be logged in to post a comment.