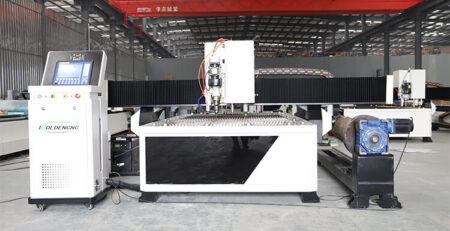

5 Axis CNC Bridge Saw Cutting Machine

What is the Bridge Saw Cutting Machine?

The 5 Axis CNC Bridge Saw Cutting Machine can realize cutting, chamfering, edging, profiling, milling, drilling, slotting, rounding, circular arc and other special-shaped processing through five-axis linkage. It is simple to operate and has strong practicability. A variety of configurations are available.

Feature

By using advanced micro computer control system to achieve multi programming methods, including manual programming or PC programming , this machine can achieve fully automatic processing operation and some powerful functions, like easy-operation auto cutting, edge polishing, slotting, kitchen countertop processing, special shape processing and other operations.

The Sample

The high-efficiency stone bridge cutting machine designed by iGOLDENCNC adopts high-strength mechanical structure, which is very suitable for manufacturers who process special-shaped stone in batches. Imported linear guide rails are used to ensure accuracy and provide a set of competitive configurations. Popular applications include:

>Decoration industry: special-shaped lines and relief carvings of stone background walls;

>Stone countertops with digging basin holes and European borders: suitable for cabinet artificial stone, quartz stone, granite, marble countertops and sinks, kitchen countertops, bathroom countertops, special-shaped bar counters, stone coffee table countertops, basin hole cutting, back-arc water forming And polishing, etc.;

>45-degree side cutting, 90-degree right angle splicing and special-shaped processing;

>Drilling, grinding, trimming, carving, cutting, polishing and engraving of other special-shaped stones, ceramics, glass and ceramic stones.

Applications

Marble, Granite, stand stone, glass,headstone, tablet,such as ceramic engraving and cutting machine. Have mainly three functions: cutting, polishing the edge, cut hole in sink.

Advantage

iGS-3020 is our newly designed CNC bridge saw with compact size.

1.It is with automatic tilting machine head and hydraulic tilting work table.

2.By using advanced computer control system to achieve multi programming methods, including manual programming or PC programming ,

3.Achieve fully automatic processing operation and some powerful functions, like easy-operation auto cutting, edge polishing, slotting, kitchen countertop processing, special shape processing and other operations.

Leave a Reply

You must be logged in to post a comment.