Advantages of the Four-process CNC Router

Igoldencnc has been engaged in the woodworking industry for decades and have received many consultations from customers especially for manufacturers of panel furniture on the four-process CNC cutting machine. Today Igoldencnc will take you through the advantages of this machine.

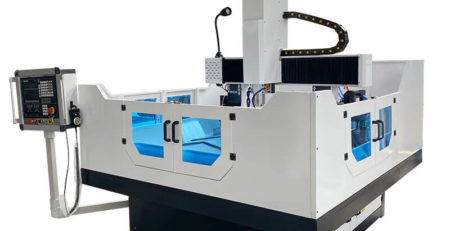

The Four-process cnc router is an economical and versatile CNC machine. Four spindles, two with high power of which are dedicated to the slotting and blanking, and the other two are dedicated to punching. In this way, different sizes of punching requirements in the production of panel furniture can be achieved. Moreover, in the production of cabinet doors, four spindles can be used to make the shape of the door. When the tool type required for the door is four or less, this machine can realize. In particular, if there is a problem with one of the spindles during use, the other spindles can still work without delaying the production. Therefore, this machine is very cost-effective.

The advantages of the Four-process cnc router:

1. Adopting advanced automatic tool change program, and program automatically executes machining requirements without manual intervention. Multiple spindles work at the same time, effectively improving machining efficiency.

2. Equipped with full absorption vacuum table, and the vacuum pump with strong adsorption force can strongly adsorb materials of different sizes, greatly improving work efficiency.

3. The machine bed is treated by a giant gantry and subjected to high temperature tempering to ensure small deformation, good rigidity, high strength, firmness and deformation, and durability.

4. Equipped with high-torque servo motor, high-precision gear and imported rack drive, which make the machine have the advantages of stable operation, low noise, high speed and high positioning accuracy.

5. Powerful vacuum system to ensure no dust flying during processing.

6. Adsorption system to ensure that in the process of processing does not lost the board to greatly improve the processing efficiency and avoid the waste of the board.

7. Oil filling system can automatically oil according to the time setting, to ensure the lubrication of the slider screw guide rail, extend the service life of the machine.

8. Intelligent control system, the control interface design is user-friendly, the operator does not need to train to operate.

9. With breakpoint memory, power-off continuous carving, processing time prediction and other functions, it is more smarter.

Applicable industry

This machine can complete diversified processing such as chamfering, punching, and engraving in panel furniture, cabinet wardrobe, office furniture, custom furniture, wardrobe cabinet, cabinet cabinet, computer desk, panel furniture, office furniture, wooden speakers, wooden kitchen utensils, etc.

These all fully explain the reasons for the popularity of this four-step CNC cutting machine. If you also have processing requirements in the above industries, please contact us.

Leave a Reply

You must be logged in to post a comment.