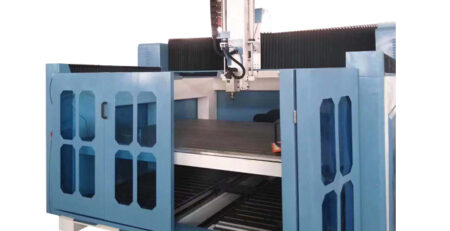

Bridge saw cutting machine Q & A

Manufacturing stones are complex, challenging, you need to pay attention to many of the problems that may occur during working in this environment. It is important to understand the problem that may occur when using stones on the bridge saw cutting machine.

IGOLDENCNC is a trustworthy professional stone manufacturer, and we better make recommendations to use our tools and consumables to ensure effective and safe work.

Through our recent issues and answers sessions, our technical sales team and our distinguished customer reading.

Question 1: “When I cut the stone with a bridge saw cutting machine, I will overruption over.”

Answer: “The most likely reason for excessive wear is that the blade is not right, your speed is too low, or the blade is not well cooled, wearing bonds. We recommend that you try to use a hard-bonding blade and increase the speed To ensure that you provide the best opportunity for your blades. ”

Question 2: “The bridge saw cutting machine body is uneven, it will affect cutting.”

Answer:“Usually, when the blade does not cool or use the wrong speed, this is what we will see. Make sure your feed and speed is correct to ensure the key and completion of the blade life. Another reason Is the blade you use is not a material that you are working hard. ”

Question 3: “When I use bridge saw cutting machine, the body of the blade is cracking.”

Answer: “Possible reasons may shorten the factors that cause the blade crack and break into the body. If the blade is over-distorted or there is not enough coolant, it may cause the problem you see. In addition, if you are too high RPM Cut, this may also cause physical damage. If you are experiencing cracking or rupture of the blade, then we recommend adding the water to cut, and always ensures that the blade is perpendicular to the cutting direction to ensure the ideal finish. ”

Question 4: “Blade overheat!”

Answer: “The overheating blade is a common problem, affecting the blade cutting quality and the lump life of the blade. If you find that the blade is overheating, you need to ensure that the blade is perpendicular to the cutting direction and increase the water flow to maximize its cooling effect. In doing so, you can ensure that you try to ensure the risk of overheating inserts. ”

Question 5: “The blade does not cut …”

Answer: “The onset that does not cut at all is likely to be due to the blade. If the material is too hard to the blade, it will not effectively cut; another reason for the blade can not cut the RPM too high. We recommend studying you The blade used is suitable for material and replaced if necessary.

Question 6: “The section of the blade is crack …”

Answer: “The crack film is another problem that can be caused by using the blade, which is not suitable for cutting materials and RPM too high and overheating. We recommend showing blade and understanding, if it is suitable for material, reduce RPM and ensure cutting There is a lot of water in the water.

Question 7: “One part of the blade has been damaged!”

Answer: “The segment of breaking the blade is not ideal, which can shorten to many factors, including; the blade is damaged in storage or transportation, excessive distortion during the cutting process, the movement of the material during the cutting process is not suitable for materials. We recommend You check that the blade being used can be cut. Another consideration is therefore absolutely determined that the blade is perpendicular to the cut. “

Leave a Reply

You must be logged in to post a comment.