Metal Laser Cutting Machine for Home

In the realm of DIY and small-scale fabrication, the demand for precision, versatility, and efficiency has been steadily growing. As home workshops and hobbyist spaces continue to evolve, the integration of advanced cutting technologies, such as metal laser cutting machines, has become a game-changer for the modern-day craftsman. These cutting-edge tools are poised to revolutionize the way you approach your projects, unlocking new levels of creativity, productivity, and professionalism in your home workspace.

Metal Laser Cutting Machine for Home

Metal laser cutting machines have long been the domain of industrial and commercial settings, but their integration into the home workshop has opened up a world of possibilities for DIY enthusiasts, hobbyists, and small-scale manufacturers. These compact, yet powerful machines offer a multitude of benefits that can elevate your home-based fabrication capabilities.

Small Metal Laser Cutting Machine for Home

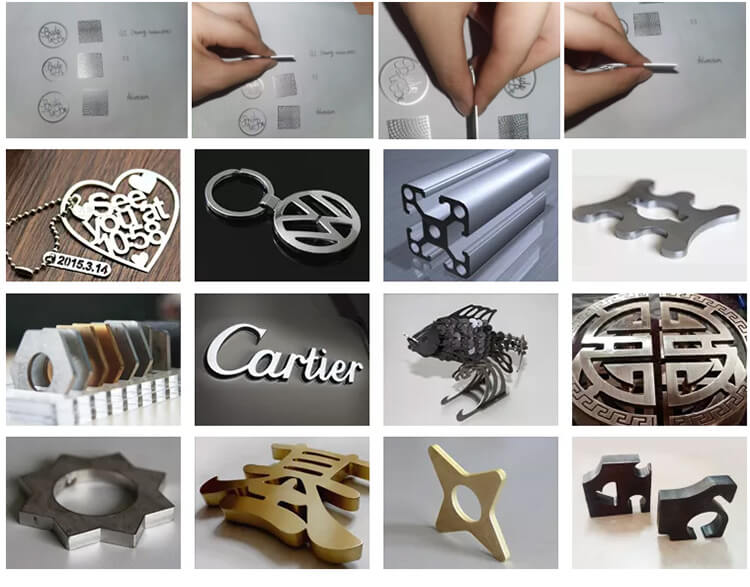

Mini hobby metal laser cutting machines are designed for personal or small-scale use, such as for hobbyists, DIY enthusiasts, or small businesses, who need to cut and engrave metal materials. Laser cutting machines are typically smaller and less powerful than industrial-grade laser cutter for metal, but they are still capable of cutting through thin metal sheets and plates, such as aluminum, brass, and stainless steel.

A small metal laser cutting machine is a compact-sized device designed specifically for cutting metal materials using laser technology. These machines are often preferred for their versatility, precision, and ease of use.

Small Laser Metal Cutting Machine Technical Data

| Technical Parameters | |

| Processing format | 600*500mm |

| Countertop load-bearing | 60KG |

| Machine weight | 800KG |

| Z-axis travel | 80mm |

| Max. linkage speed | 50m/min |

| Max. acceleration | 0.6G |

| positioning accuracy | 0.03mm |

| Repeat positioning accuracy | 0.02mm |

| Machine size | 1250mm(L)*1150mm(W)*2050mm(H) |

| Configuration checklist | |

| Control System | Taytools |

| Laser | MAX |

| Motor | Fuji Electric Japan |

| Cutting head | Taytools |

| Cooling method | S&A |

Portable Metal Laser Cutting Machine for Home

Metal laser cutting machine (also known as laser cut steel machine,stainless steel laser cutter) is a CNC machine that uses a powerful laser beam to cut stainless steel, carbon steel, aluminum plate, brass and other metal sheets. A laser metal cutter works by directing a laser beam along a material to create very precise cuts, shapes or designs.

Laser cutting machine for metal is commonly used in machinery manufacturing, advertising industry, kitchen appliances, elevator industry, shipbuilding and other industries, but they can also be used for personal or hobby purposes.

A laser machine is an excellent addition to any small business. The best machines are compact, user-friendly and cost-effective. For high volumes of thin metal sheets, a fiber laser machine is the best choice because of the excellent cut quality, high cut speeds and low operational costs.

Portable Gantry CNC Laser Cutting Machine Parameter

| Index | Parameter |

| Model | iGR-P3015 |

| Table | 3000*1500mm |

| X-axis travel | 1500mm |

| Y-axis travel | 3000mm |

| Z-axis travel | 100mm |

| X/Y axis positioning accuracy | ±0.08mm |

| X/Y axis repeated positioning accuracy | ±0.05mm |

| X/Y axis max. moving speed | 50m/min |

| Max. acceleration | 0.5G |

| Weight | Equipment 550kg+ Optional table 190kg |

| Voltage | 380V/50Hz |

HomeLaser Cutting Machine for Metal Sheet and Tube

Plate and tube dual-purpose fiber laser cutting machine, can achieve two different profile cutting on the same machine tool, can cut metal sheet and pipe (square pipe, round pipe, channel steel, Angle steel, etc.). A multi-purpose machine, high cost performance, professional pipe cutting numerical control system, high precision, full function, easy to use, simple operation, suitable for comprehensive processing and manufacturing enterprises.

A laser machine is an excellent addition to any small business. The best machines are compact, user-friendly and cost-effective. For high volumes of thin metal sheets, a fiber laser machine is the best choice because of the excellent cut quality, high cut speeds and low operational costs.

Portable CNC Laser Cutting Machine Parameter

| Index | Parameter |

| Power | ≤3000W |

| Model | iGR-P3015T3 |

| Working area | 3000*1500mm |

| X/Y axis positioning accuracy | ±0.08mm |

| X/Y axis repeated positioning accuracy | ±0.05mm |

| X/Y axis max. moving speed | 50m/min |

| Max. speed of movement on the Z axis | 30m/min |

| Max. acceleration | 0.5G |

| Max. pipe weight | T160: 140Kg 23Kg/m |

| Max. blanking length | 2m |

| Min. surplus | ● 300mm 130mm(Add open detection, add expansion board) |

| Voltage |

Bringing Metal Laser Cutting into Your Home Workshop

Integrating a metal laser cutting machine into your home workshop can be a transformative step, empowering you to elevate your fabrication capabilities and explore new creative avenues. Here are some key considerations when selecting the right machine for your needs:

- Workspace Size: Assess the available space in your home workshop and choose a machine that fits comfortably without compromising your work area.

- Power Requirements: Ensure that your home’s electrical infrastructure can accommodate the power demands of the metal laser cutting machine.

- Material Compatibility: Determine the types of metal materials you plan to work with and select a machine with the appropriate cutting capabilities.

- Automation and Digital Integration: Look for models that offer user-friendly controls, automated features, and seamless integration with design software to streamline your workflow.

- Safety Features: Prioritize machines with robust safety mechanisms, such as enclosures, ventilation systems, and emergency stops, to protect you and your workspace.

Application Materials:

CNC Metal laser Cutting Machine is suitable for quality cutting of stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, aluminum-plating zinc plate, copper, and other metals.

Conclusion:

The integration of metal laser cutting machines into the home workshop arena has ushered in a new era of precision, versatility, and efficiency for DIY enthusiasts and small-scale fabricators. By harnessing the power of this advanced technology, you can unlock a world of design possibilities, enhance the quality of your projects, and establish your home workspace as a hub of creativity and innovation. As the demand for cutting-edge tools continues to grow, embracing the transformative potential of metal laser cutting machines will be a strategic investment that can propel your home-based fabrication endeavors to new heights of success.

Leave a Reply

You must be logged in to post a comment.