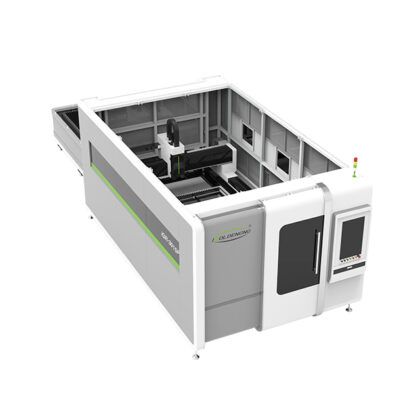

Protective Fiber Laser Cutter Machine with CE Certificate

Item No.: iGR-P

Protective fiber laser cutter also called protective fiber laser cutting machine, enclosed fiber laser cutter, laser cutter, metal laser cutter, metal laser cutting machine, designed for high precision metal plate cutting processing with full-coverd. This model is the upgrade level for metal plate cutting at affordable price.

Category: Laser Machine>>Laser Cutters

Response time: Within 1 hour

Supply Ability: 200 sets/month

Price Range: $30000-$163500

Description

Who is it for?

The safest protective fiber laser cutter machine with protective glass window, perfect for metal plate cutting processing, the welding body offers the robust construction that iGOLDENCNC products are known for, combined with a competitive set of configurations.

Hot applications is cutting for stainless steel, carbon steel, aluminum, copper, galvanized sheet and other metal plate.

What makes it unique?

Popular with metal processing users, the iGR-P series protective fiber laser cutter machine is suitable for manufacturers who just joined the industrial or started the metal cutting business.

>Full-enclosed model, safer and eco-environment;

>High precision, perfect cutting result;

>Heavy industry quality, stable operation for 10 years;

>Easy to operate, quick obstacle removal, conducive to learning;

>Supported by industry leader iGOLDENCNC.

Application of Protective Fiber Laser Cutter Machine

Stainless Steel Cutting

S.S Accessories Cutting

Carbon Steel Cutting

Cutting for Hardware

Cutting for Metal Letters

Cutting for Car Parts

Cutting for Metal Box

Cutting for Metal Shelf

| Working Area | 3000*1500mm |

| Dimensions | 4400*2500*2200mm |

| N.W | 2000kg |

Features of Protective Fiber Laser Cutter Machine

Options of Protective Fiber Laser Cutter Machine

For the fiber laser cutter, the price is different according to the function and configuration. Please contact us for more details.

It depend on the material thickness you want to processing and the running frequency of the machine. Please let us know which material do you want to process and the thickness.

The metal laser cutter is only for metal sheet, such as stainless steel, carbon steel, copper, aluminum, iron, galvanized, etc..

Do you need a catalogue, price or machine working video?

Please let us know your name and email, we will send you more information asap

Be the first to review “Protective Fiber Laser Cutter Machine with CE Certificate”

You must be logged in to post a review.

Reviews

There are no reviews yet.