Which woodworking engraving machine is good ?

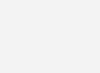

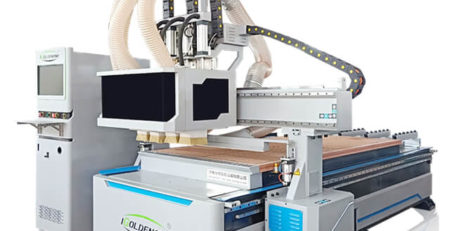

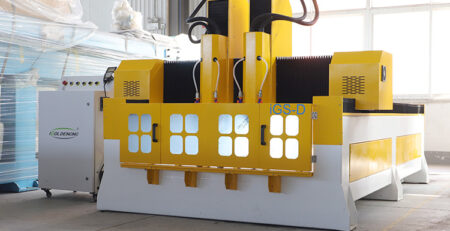

Antique furniture is becoming more and more popular these days. The production of furniture is naturally inseparable from a piece of mechanical equipment – woodworking engraving machine. The application of woodworking engraving machine in furniture engraving uses milling and hollowing out to process furniture products.

Use the engraving machine to make antique furniture, such as screens, wine cabinets, TV cabinets, display cabinets, vertical cabinets, etc. If you use woodworking engraving machine to make antique furniture, there are many engraving machine companies now, the quality of products is also very different, and the level of craftsmanship is also different.

Use the engraving machine to make antique furniture, such as screens, wine cabinets, TV cabinets, display cabinets, vertical cabinets, etc. If you use woodworking engraving machine to make antique furniture, there are many engraving machine companies now, the quality of products is also very different, and the level of craftsmanship is also different.

Maintenance of woodworking engraving machine

The continuous running time is less than 10 hours a day to ensure the cleaning of cooling water and the normal operation of the water pump. The water spindle motor must never be short of water. The cooling water should be replaced regularly to prevent the water temperature from being too high. In winter, if the working environment temperature is too low, the water in the water tank can be replaced with antifreeze.

After each use of the machine, pay attention to cleaning, be sure to clean the dust on the platform and the transmission system, and lubricate the transmission system (X, Y, Z three axes) regularly (weekly). (Note: the X, Y, Z three-axis guide rails are maintained with oil; the screw part is added with high-speed butter; the temperature of the working environment in winter is too low, the screw rod and square guide rail or round guide rail) part should be rinsed with gasoline first, and then refueled, otherwise The resistance of the transmission part of the machine is too large. Lubricate with screw loosening lubricant if necessary.

Maintenance and inspection of electrical appliances

Maintenance and inspection of electrical appliances

When the engraving machine does not work properly, it may be due to a problem with its internal parts or other reasons. The following is a general introduction to frequently asked questions.

One of the three axes cannot be moved. At this time, check whether the drive block corresponding to the corresponding axis is damaged. The inspection method can be replaced by the replacement method: unplug the aviation plug corresponding to the fixed shaft, and insert the driver corresponding to the other drive shaft.

If the stationary axis moves normally after replacement, it means that the drive block corresponding to the axis is damaged and the drive block needs to be replaced. If the shaft still doesn’t move, the cable or motor is faulty. Replace the cable or motor. All three axes cannot be moved. At this time, check whether the three-axis aviation plug is connected to the control box and whether the power supply of the control box is turned on. Whether the data cable is well connected with the control box and control card in the host. If the above is normal, please contact the manufacturer.

The spindle does not operate normally. First check the error code displayed on the LED display of the inverter (refer to the error code item in the inverter manual), fault code: DL output short circuit Check whether the motor and cable are short-circuited, whether the voltage input voltage is abnormal Check the input power supply OH Overheating load is too large, The cooling fan is damaged, reduce the load and replace the fan (Note: when the inverter displays DL, the reset button is invalid, please power off and restart the inverter to troubleshoot) Common TALENT series inverter (2.2kW) faults and solutions Fault code: EOCD Output short circuit Check motor and cable for short circuit EOU Input voltage is too high Check voltage EOCN Output circuit phase-to-phase or ground short circuit Check wiring and motor ELU in the same power system Load starting current is large Avoid load wiring TL External interference Separate control wire from strong current

The water pump is working and the circulating water is normal. Motor overload and internal fault (please contact the manufacturer) If the motor is connected reversely, check whether the motor wire is reversed, and both ends of the output UVW terminal can be switched arbitrarily.

The application of woodworking engraving machines is becoming more and more extensive, and the maintenance of the equipment during use is also very important. After the work of the woodworking engraving machine is completed, the work surface should be cleaned in time to prevent it from being stuck, and the debris of the guide rail must also be cleaned up. In addition, the lead screw is very important in the equipment, so regular cleaning of the lead screw can effectively prevent foreign matter from adhering to the lead screw.

Oiling plays an important role in the maintenance of woodworking engraving machines. When refueling; the refueling cycle is generally once every two weeks; after refueling, remember to walk back and forth at a slow speed to ensure lubrication; even if the woodworking engraving machine is not used for a long time, it should be refueled and emptied regularly. Last but not least, when replacing parts, regular inspections and maintenance are required to ensure their excellent performance. During the inspection process, we often overlook the inspection of new replacement parts.

Leave a Reply

You must be logged in to post a comment.