2D & 3D 4 Axis CNC Milling Machine

What is the 4 Axis CNC Milling Machine?

The 2D&3D integrated woodworking router 4 Axis CNC Milling Machine is a multifunctional high-efficiency wood CNC machine for sale, which can both engraving three-dimensional cylindrical and batch engraving planes, and multiple spindles can be processed at the same time, which meets the needs of small-format batch processing production.

WHAT IS 4-AXIS MACHINING?

4-axis milling involves the same processes involved in 3-axis machining, where a cutting tool is used to remove material from a piece to create the desired shape and profile. However, in the case of 4-axes machining, milling is performed on an additional axis. A 4-axis CNC machine operates on the X,Y and Z axes like a 3-axis machine, but it also includes rotation around the X-axis, which is called the A-axis. This is the 4th axis that’s added to our machining process. In most cases, the workpiece will be rotated to allow for cutting to occur around the B-axis.

4-axis milling is useful when holes and cut-outs need to be made in the side of a piece or around a cylinder. They can provide quick and efficient work based off computer numerical inputs for precise results.

Advantage

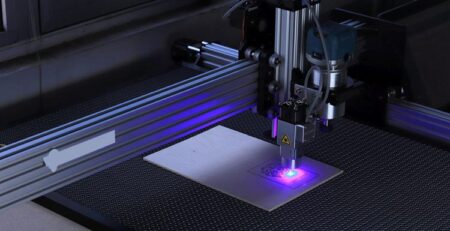

CNC (computer numerical control) machining is a process in manufacturing where programmed computer software directs the motions of plant machinery and tools. The application can be used to automate a range of manufacturing techniques such as milling, water jet cutting, and laser cutting materials. Instructions are fed into the CNC machine through a CAD file and transposed into a precise set of sequential instructions. The CNC machine uses these programmed commands to operate automatically without a physical operator. Manufacturers accrue several benefits through the application of CNC machining such as expense reduction, improved speed, better accuracy, and enhanced productivity levels.

The reference to axes is used to describe CNC machines which operate along multiple axis points. CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth). The 4th axis denotes the inclusion of an A axis (rotation around the X axis), and the 5th axis denotes the B axis (rotation around the Y axis).

4 Axis

4 axis machining implies that a workpiece is processed in the same way it would be with a 3 axis machine, but has an additional rotary movement around the X axis, which is named the A axis. This rotation allows the workpiece to be cut around the B axis. This method is beneficial when holes or cuts need to be made on the sides of a workpiece. The addition of a fourth axis (A axis) allows a workpiece to be automatically flipped over, so the machine can remove material from both sides. 4 axis machining is multifunctional and can be used for:Intermittent cutting, Continuous cutting, Engraving curved surfaces

Application

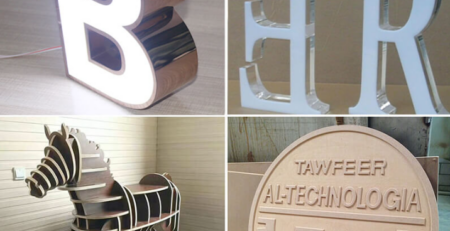

Advertising signs, logo making, acrylic cutting, PP/PE/ABS/PVC/PC Board Cutting engaving, making of various materials, decorative products, and wood relief engraving or cutting,like wood window processing, wood table, chairs,wood doors, Woodenworking Industry , 3D Wave Board Provessing , Cupboard Doors, Crafts Wooden Doors ,Unpainting Door ,Screen ,Crafts Windows ,Milling and Endraving On The Furniture,etc

Leave a Reply

You must be logged in to post a comment.