3D foam model using CNC foam cutter

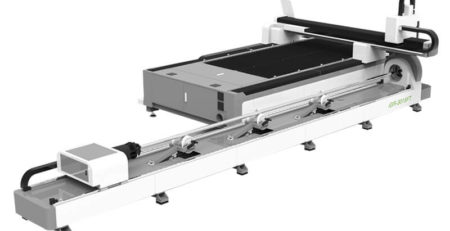

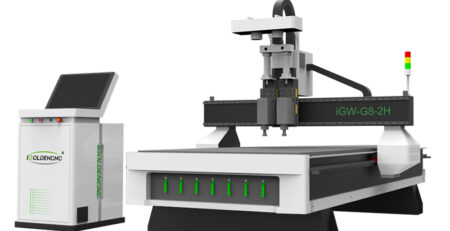

The company is using the hot wire cutter to cut any 2D foam shape that requires flat surface. When you need 3D shapes, you need to use a CNC foam cutter for sale.

The CNC foam cutter for sale uses a 3D shape of the machine. It is a shaft machine that means it moves in the diagonal and curves in 3D space to similar to the abrasive or engraving. The router can create a 3D design from many types of materials, including:

EPS foam, urethane foam, aluminum, shallow wooden, acrylic, plastic and polycarbonate and ABS. Processing processes involves creating a 3D model using 3D CAD software, then bringing the model into the 3D tool path, which will tell the router’s shape size, resolution, cutting direction, cutting depth, and the like.

It can be almost unlimited using the shape of the CNC foam cutter for sale.

Applications and Industries:

* Car – full scale car, ship, plane

* Aerospace – drone model

* Architecture – any 3D architectural shape

* Art, sculpture, statue

* Ocean – vessel, ship model

* Museum – 3D Display, Face, Statue

* Navigation – topographic map

If you want to design a 3D model, and due to the height or tool length limit or the foam material is not thick enough, and the foam material is too large or too large, it can be partially done. Each slice will use the router separately, which can then bond the debris. Then, the machined components can be sanded and coated with protective hard shells and painted, which will also pay attention to any visible groove due to gluing. The router can also be used to create a mold that can be poured with concrete or polyurethane and other cast materials.

The range of CNC foam cutter for sale has been 50 feet from several inch workspaces.

Each router uses a spindle – it is a motor that is doing actual cut. The spindle range of the router ranges from 1 HP (horsepower) to 20HP and above, they can put the end mill from 1/16 “until 2” and above.

Different materials require different end mills and different cutting speeds. A more dense material cutting speed is slow.

If you need to create a large or even full-scale foam shape design, you can use a small model to scan it with a 3D scanner, and then transfer it to the CNC foam cutter for sale using the special cutting software generated by the generated part file for processing. Use the scanner to enable you to convert any conventional models to real-time design. Any model can be scanned – facial, sculpture, car toys, trains, boats, plains, and anything you need to be bigger. You don’t have to visualize and imagine how the 3D model looks like – the scanner is available.

In recent years, 3D printers have become more popular, more easily and handling multiple materials, thereby being more popular. They can be used to create prototypes in endless types, including industrial manufacturing, automotive, aerospace, national defense, pharmaceutical, medical, dental and health care, sports, art, architecture, hobby models, consumer goods and electronic products. Not only is 3D printing in economic and delayed interests, but its production process introduces more ecological methods for creating products – rather than a lot of waste that needs to be recycled. In fact, the future of product development and manufacturing is now in the hands of those revolutionary high-tech printers.

Leave a Reply

You must be logged in to post a comment.