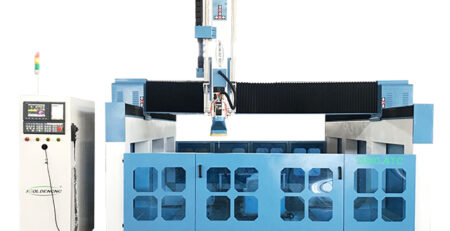

All-in-one laser cutting machine_All-in-one laser cutting sheet and pipe machine

Tube-to-sheet integrated laser cutting machine has high precision! Stable performance! Micro-focusing spot, extremely fine slit! Pneumatic chuck, fast movement! D-type tube/hexagonal tube/I-beam/angle iron and other types of materials! Tube-sheet integrated fiber laser cutting machine is also known as tube-sheet dual-purpose laser cutting machine and plate-and-tube integrated laser cutting machine. 4020, 6015, 6020, 6025, 8025 fiber laser cutting power can be optional 1000w, 1500w, 2000W, 3000W, 6000w, 8000w, 12000w cutting square tube, round tube, rectangular tube, D-shaped tube and hexagonal tube and other types Pipe.

Advantages of laser cutting machine

- Highly integrated, long service life;

- It integrates laser engraving and cutting functions;

- Can be used for stainless steel, carbon steel and other materials;

- It can process various pipes such as round pipes, oval pipes, square pipes, rectangular pipes;

- The diameter and length of the processed pipe can be customized according to customer needs;

- A variety of imported and domestic lasers with different powers are available;

- Advanced chuck clamping system, automatic center positioning;

- Fully intelligent numerical control system, man-machine exchange operation interface;

- Optional automatic loading and unloading system

- High efficiency and energy saving greatly reduce the manufacturing cost;

- Very low equipment maintenance requirements;

The plate-and-tube integrated fiber laser cutting machine can meet the processing requirements of plates and tubes of different thicknesses at the same time. The tubes that can be cut include round tubes, square tubes, rectangular tubes, and elliptical tubes. It can cut plates and tubes of various metal materials, including stainless steel, Carbon steel, galvanized sheet, various alloy sheets, rare metals, etc. Plate and tube integrated fiber laser cutting machine is an integrated cutting machine for metal sheet and metal tube processing, with a standard working area of 3000*1500mm and 6m, which can be widely used in stainless steel, carbon steel, aluminum, copper and other metal plates and tubes, and Can be equipped with 1000-6000w laser source for plate and tube cutting of different thicknesses.

The plate-and-tube integrated fiber laser cutting machine can meet the processing requirements of plates and tubes of different thicknesses at the same time. The tubes that can be cut include round tubes, square tubes, rectangular tubes, and elliptical tubes. It can cut plates and tubes of various metal materials, including stainless steel, Carbon steel, galvanized sheet, various alloy sheets, rare metals, etc. Plate and tube integrated fiber laser cutting machine is an integrated cutting machine for metal sheet and metal tube processing, with a standard working area of 3000*1500mm and 6m, which can be widely used in stainless steel, carbon steel, aluminum, copper and other metal plates and tubes, and Can be equipped with 1000-6000w laser source for plate and tube cutting of different thicknesses.

Tube-to-Sheet Integrated Fiber Laser Cutting Machine is a plate-to-tube integrated fiber laser cutting equipment (tube-to-plate dual-purpose laser cutting machine|tube-to-plate dual-purpose metal fiber laser cutting machine|tube laser cutting machine) launched for customers who need both sheet metal cutting and pipe cutting. It has the advantages of stable performance, high efficiency and energy saving, and high cost performance. IGR-3015 professionally cuts various types of pipes such as square pipe, round pipe, rectangular pipe, D-type pipe and hexagonal pipe, square pipe 20*20 – 100*100mm, round pipe Φ20-Φ150mm, pipe wall thickness 0.5- 5mm carbon steel pipe, 0.5-3mm stainless steel pipe; cutting 0.5~12mm carbon steel sheet, 0.5~5mm stainless steel sheet, 0.5~3mm brass, 0.5~2mm copper and galvanized sheet, electrolytic sheet, silicon steel and other metal materials (thickness and material related to the laser)

The tube-sheet integrated machine is a product required by individual industries, and its service life and maintenance cycle are also consistent with the fiber laser cutting machine. The price of the machine is not cheap, and the good products with good after-sales are the standard for us to save worry and trouble.

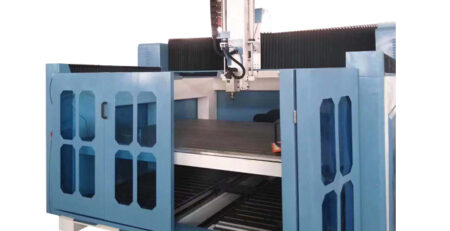

The main features of the plate and tube fiber laser cutting machine can not only reduce the floor space, but also reduce the input cost. It is an ideal choice for users who need double cutting of plates and pipes. It adopts advanced brand fiber lasers and electronic components to ensure the stability of the equipment. , Vertical cutting pipe device, providing double cutting function of sheet and pipe; drawer-type receiving tray is convenient for the collection and cleaning of debris and workpieces.

High reliability of the fuselage: high-quality low-alloy carbon steel welded beams optimized by finite element analysis. Steel structure welding bed, annealing and stress-relieving treatment accuracy is stable for a long time.

Fine and excellent machining accuracy: The well-designed high-precision and high-rigidity transmission system makes the equipment have excellent kinematic rigidity, and high-speed cutting can still ensure accurate trajectory.

High-quality cutting section: high beam quality laser, well-designed cutting head optical scheme and gas system make the cutting section smooth and flat.

Efficient cutting: XY single-axis acceleration 1.2G, XY single-axis positioning speed 80mmin.

Wide range of material processing: suitable for rapid cutting of carbon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, copper and other metal materials.

Flexible product processing mode: There is no need to prepare molds and auxiliary consumables, and it is not limited by batches and graphics. Graphics can be generated at any time and cut in real time.

Simple and easy-to-use control system: FSCUT2000 system is adopted, which is powerful, easy to learn and use, and can complete operations such as nesting and typesetting on the device.

Optimized dust removal design: The partition dust removal structure minimizes the cutting dust on the processing site.

Compact structure: fully integrated design, short installation time, the equipment can be put into production quickly after the equipment is in place. Small footprint, saving workshop space.

Plate and tube integrated laser cutting machine

One machine can be used for two purposes, which can not only meet the customer’s requirements for flat cutting, but also meet the cutting of various special-shaped pipes such as square pipes and round pipes, with higher efficiency. At the same time, it has the advantages of fast cutting in flight, fast perforation, visual collision avoidance, automatic obstacle avoidance, etc., to meet various needs.

Applicable materials for laser cutting sheet and pipe all-in-one machine:

It is suitable for stainless steel, carbon steel, alloy steel, aluminum, copper, titanium and other metal pipes, and has excellent processing effect on various high-hard and brittle alloy materials.

Application industry of laser cutting sheet and pipe all-in-one machine:

Hardware processing, precision cutting, precision instruments, medical instruments, glasses and clocks, craft gifts, auto parts, instrumentation, etc.

Leave a Reply

You must be logged in to post a comment.