Multifunction CNC Wood Carving & Cutting Machine

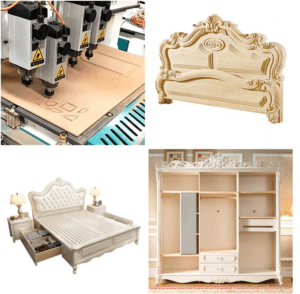

CNC wood carving and cutting machine is a versatile and efficient tool for creating precise and intricate wood products with high accuracy and repeatability. Its ability to perform multiple functions in a single machine makes it a popular choice for woodworking professionals who need to create a wide range of products quickly and efficiently.

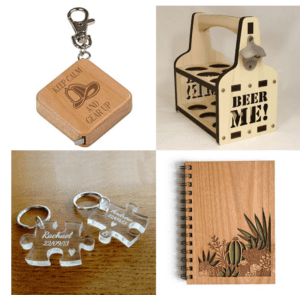

One of the key advantages of a multifunction CNC wood carving cutting machine is its versatility. It can be used for a wide range of applications, including cutting, carving, engraving, and milling. This makes it a valuable tool for woodworking professionals who need to create a variety of products quickly and efficiently.CNC wood carving and cutting machines are commonly used in woodworking shops and factories to produce a wide range of products, including furniture, cabinetry, and decorative woodwork. They are also used in the production of musical instruments, signs, and other custom woodwork.They are widely used in woodworking, furniture making, sign making, and many other industries.

Features of CNC Wood Carving & Cutting Machines:

Robust and sturdy construction: CNC machines are built with a rigid frame, usually made of steel or aluminum, to provide stability and withstand the forces generated during cutting and carving operations.

High precision and accuracy: CNC machines are controlled by computer software, which ensures that the cutting and carving operations are performed with high precision and accuracy.

Versatile functions: CNC machines can perform various operations such as cutting, carving, engraving, drilling, and milling, depending on the software and accessories used.

Wide range of materials: CNC machines can work with a variety of wood materials, including hardwoods, softwoods, MDF, plywood, and even some plastics and non-ferrous metals.

Ease of use: Most CNC machines come with user-friendly software that allows for easy design creation and editing.

Additionally, many CNC machines have features like automatic tool changers and built-in cameras for alignment and calibration.

The machine is controlled by advanced software that allows for precise control over the cutting and carving process. This software can be programmed with the desired design or shape, and the machine will then cut or carve the wood accordingly. This makes it easy to create complex designs and patterns with a high degree of accuracy and repeatability.

Multifunction CNC wood carving and cutting machines can also be equipped with a variety of other features, such as dust collection systems, vacuum tables, and automatic tool changers, depending on the specific application and desired outcome.

Leave a Reply

You must be logged in to post a comment.