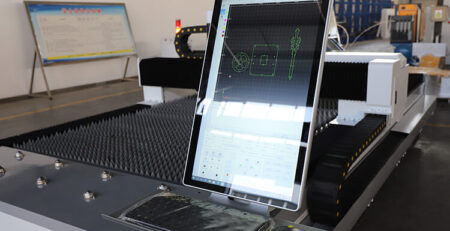

Laser Paint Remover Laser Cleaning Machine 1000w Price

Laser cleaning machine is also known as laser cleaner, laser rust cleaning machine, laser paint removal machine, laser paint stripping machine, laser coating removal machine, laser rust removal machine, laser oxide removal machine, laser dirt cleaning machine, laser oil cleaning machine, laser descaler machine.

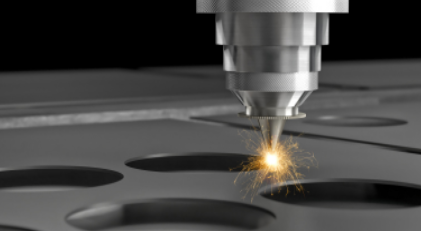

Laser cleaning machine 1000w uses high-frequency and high-energy laser pulses to irradiate the surface of the workpiece, so that the surface oil, rust or coating evaporates or peels instantly. Its characteristics are not to damage the part matrix, no consumables, energy saving and environmental protection, and efficient removal of resin on the surface of the workpiece.

Laser cleaning machine 1000w uses high-frequency and high-energy laser pulses to irradiate the surface of the workpiece, so that the surface oil, rust or coating evaporates or peels instantly. Its characteristics are not to damage the part matrix, no consumables, energy saving and environmental protection, and efficient removal of resin on the surface of the workpiece.

US $9,000-30,000 / Set

Main Features of Laser Cleaning Machine 1000w:

1 . This industrial laser cleaning machine uses non-contact cleaning without damaging the component substrate.

2 . The laser derusting machine supports precise positioning and selective cleaning.

3 . The laser metal cleaning machine does not need to use any chemical cleaning liquid, does not need consumables, and is safer and environmentally friendly.

4 . Simple operation, hand-held or with the robot arm to achieve automated cleaning.

5 . Optical fiber laser transmition, it is very esay and quick for the laser derusting machine to clean and remove the dust.

6 . Laser cleaning system is stable, no maintenance.

7 . Automatic smoke purification device is optional according to customer’s needs.

Compared with chemical cleaning, Laser cleaning machine 1000w does not need any chemical agents and cleaning fluids . Compared with mechanical cleaning, the laser metal cleaning machine has no w ear and tear , no consumables , and less damage to the substrate. Wide range of applications. The technology of the laser metal cleaning machine has been applied internationally in all fields

The market prospect of laser cleaning machine is broad. Daily industrial products and professional industrial products must use one or several of the surface treatment technologies to realize the functions required by the product design or the market. In the process of electroplating, phosphating, spraying, welding, packaging and integrated circuit assembly of industrial products, grease, dust, rust, residual solvents, adhesives and other dirt on the surface must be removed to ensure the quality of the next process . The current cleaning methods widely used in the cleaning industry include mechanical cleaning, chemical cleaning and ultrasonic cleaning, but their application is greatly restricted under the constraints of environmental protection and the requirements of the high-precision market. The laser cleaning machine has obvious advantages in various industries.

Leave a Reply

You must be logged in to post a comment.