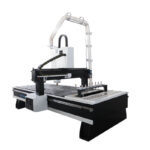

Wood Carving ATC CNC Router Machine 1325

Item No.:ATC CNC Router iGW-1325

1325 CNC Router With Linear Tool Changer For Woodworking-With 9.0kw HSD ATC spindle and carousel tool changing magazine, the machine can change tools automatically during the work. Working area is1300*2500*250mm, widely used in furniture industry.

If you need more detailed information, please inform us as soon as possible.

Description

Automatic tool changer (ATC) CNC Router machine is suitable for the processing of various complex products or a variety of processing. It can be equipped with 6, 8, 10, 12 tools according to the different production process requirements of customers. There are two tool change modes for inline tool change and disc tool change. Widely used, including engraving, milling, chamfering, side milling, drilling, cutting, grooving, etc.

This 1325 atc cnc router adopting linear tool change mode, the tool change speed is fast, and the automatic tool change function can be realized in a few seconds. It is worth mentioning that this machine is equipped with automatic feeding device, which not only saves the time and effort of manual feeding, but also greatly improves production efficiency. Therefore, the ATC CNC router is the first choice for large enterprises or enterprises with large production volume.

- With 8 or 12 sets of tools to change automatically, which can saving time of tools changing and improving working efficiency.

- Vacuum table using high-density material with great suction strength, comfortably accommadating all sizes of work piece.

- NC studio control system is simple, convenient and easy to learn, users can quickly get the fleciblity to master the use of equipment, strong independence.

- The frame adopts the gantry column structure, the machine parts are produced and assembled with extremely high precision to ensure the high performance and stability of the machine, excellent quality and tolerance.

CNC Wood Router Machine Applications

Woodworking industry:

Solid wave board process,door of cabinet,wooden door,artistic wooden door ,no-paint door,avoid wind,process of the artistic window,shoes cleaning machine,the cabinet of the playing machine and the board, mahjong table,computer table .c.ny furniture carving, solid wood art fresco carving and other industries.

Advertising industry:

Advertising board,Label design,Acrylic cutting,model, of the multi material decoration products.

Model industry:

It can engrave on the metal materials such as copper, aluminum ,iron etc and non-mental material.s such as man-made marble,sand, plastic board PVC materials, wood board etc.

Art industry:

Character carving, character carving and cutting, famous brand making, small gift cutting, souvenir making, carving various decorative letters, small windows, fences, figures on walls, etc.

Other industries:

CNC wood engraving machine can engrave all kinds of large reliefs and shadows, which are widely used in craft gift industry.

Wooden Window Hollowing

Wooden Crafts Embossing

Wooden Door Processing

Plastic Carving

Wooden Furniture Processing

Cabinet Door Processing

Wooden Crafts Relief

Acrylic Cutting

iGOLDENCNC, Your best choice

Becoming a customer of iGOLDENCNC, we will cooperate with you on the basis of complete trust and comfort. You will find that we are a reputable supplier and worth your trust. We understand that every customer is valuable, and we will cherish every opportunity to cooperate!

Strict Quality Control System

Advanced testing equipment are used, such as: dynamic balance tester, CNC high precision machining machine, 3D measuring machine; iGOLDENCNC has established a complete and strict quality control system, including 48-hour running test and 72-hour aging test, to ensure the excellent quality of our machines.

FAQ

Woodworking industry: Processing of three-dimensional wave board, cabinet doors, solid wood doors, craft wooden doors, paint-free doors, screens, craft window, and auxiliary processing of shoe polishers, game machine cabinets and panels, mahjong tables, computer tables and panel furniture. Advertising industry: Advertising signage, logo making, acrylic cutting, plastic molding, and processing of various advertising materials and decorative products. Mold industry: It can engrave copper, aluminum, iron and other metal molds, as well as artificial marble, sand and stone, plastic plates, PVC pipes, wooden boards and other non-metal molds. Craft gift industry: It can carry out a variety of shadow carvings, reliefs, and widely used in crafts industry.

First, high productivity. Equipped with automatic tool changing device, which can meet the tool changing requirements during processing without manual participation. With simple and easy operation mode to learn, which can help users quickly grasp the use of methods and greatly improve production efficiency. Second, imported spare parts. Adopting the automatic tool changing spindle, it has the advantages of good starting performance, fast processing speed, large torque and high processing efficiency. Adopting Italy HSD spindle motor, and spindle bearings with high-precision ceramic bearings, it has the advantages of low noise and long service life. Equipped with the imported high torque servo motor, it has the advantages of low noise, fast speed and high positioning accuracy. Equipped with a unique tool changing device and a dedicated tool setting table, it can realize automatic tool changing without intermittent with fast tool changing speed, and can accurately compensate for tool length errors. Adopting Taiwan linear guide and ball screw, it has the advantages of high bearing capacity and accurate cutting. Third, good software compatibility. Adopting open software interface, it can be compatible with the processing codes generated by various CAD / CAM design software, such as type3 / Artcam / Castmate / Wentai, to ensure the realization of various design functions.

ATC CNC router is the first choice for enterprises with large production volume. Compared with the traditional manual tool change production method, this type of wood CNC machine has an independent tool magazine with different tool bits. It can automatically change the required tools by computer program control without stopping work during processing. And this CNC wood router can complete a series of cutting, hollowing, grooving, punching, milling grooves, milling planes and other different processing needs. Therefore, both the processing quality and processing efficiency have been greatly improved.

Every size is possible, the size and diameter is optional.we can product any size according your request.

The working efficiency of the engraving machine is closely related to the complexity of the pattern, the processing depth, and the difficulty of material processing. So time is not easy to estimate.

Related Products

Do you need a catalogue, price or machine working video? Please let us know your name and email, we will send you more information asap.

Be the first to review “Wood Carving ATC CNC Router Machine 1325”

You must be logged in to post a review.

Reviews

There are no reviews yet.