Several advantages of automatic laser marking machine

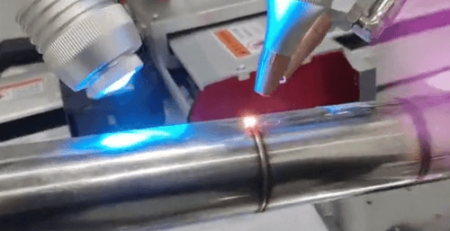

The laser marking machine has high precision, the speed of light of the laser is very fine, and it acts on the surface of the material, and the small repositioning accuracy can reach 0.01mm. It is suitable for the marking of fine instruments and parts. The current precision can meet the needs of marking on extremely small plastic and metal surfaces. For example, the common two-dimensional code has stronger market competitiveness than imprinting or jet marking.

Then let’s talk about the eight advantages of laser marking machine, as follows:

- Laser marking machine is a physical non-contact processing. There is no pollution source of any chemicals, and it is not limited to the shape of processed items, such as round and square. Arc can be;

- The laser marking machine is suitable for a wide range of materials. It can mark almost all metal and non-metallic materials (such as aluminum, stainless steel, glass, leather, cloth, paper, etc., different materials, different thicknesses, and different hardness materials);

- Good compatibility, auxiliary and other processing equipment to form a fully automated production line;

- The marking of the laser marking machine is clear and beautiful, durable and wear-resistant, and it is not easy to be altered and covered, which plays an anti-counterfeiting role to a certain extent;

- The laser marking machine has a long service life, the core of the whole equipment is the laser, and the service life is also more than 20,000 hours;

- The post-processing and maintenance costs are low. The marking speed is fast and the marking is formed at one time, and the energy consumption is small, so the running cost is low. Although the initial equipment investment of laser marking machine is higher than that of traditional marking and coding equipment, it is more cost-effective to use laser marking machine in terms of later operating costs;

- High processing efficiency. The laser beam under computer control can move at high speed (up to 7000mm/s), and processing a conventional product can be completed in a few seconds. The laser marking machine system is equipped with a computer control system, which can flexibly cooperate with the high-speed assembly line to greatly improve the processing efficiency;

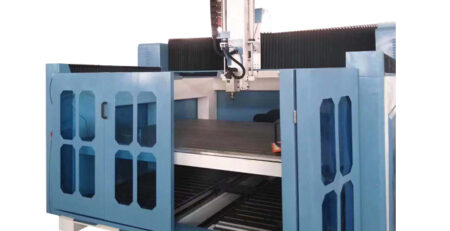

- The laser marking machine has lower requirements on the processing environment. The length and width of conventional laser marking machines are mostly more than one meter, occupying a small area, and only need to use electricity.

Application of laser marking machine laser engraving machine?

Application of laser marking machine laser engraving machine?

- Application of laser marking machine:

(1) Applied to all kinds of metals: marking of electronic hardware accessories industry. Many people may not understand that some hardware accessories and electronic components will be marked with laser marking machines. For materials with more friction such as automobiles, ships, machinery, and equipment, laser marking can be wear-resistant and help the industry to mark.

(2) Used in IT industry, communication industry, machinery manufacturing industry, food and drug, medical equipment, clocks and glasses, craft gifts, precious metal jewelry, leather clothing, packaging and printing stoves, precision hardware, accessories, electrical appliances, instrumentation and other metals processing industry.

(3) Application through polymer materials, electronic components, wire speed limiters, reflective films, plastic buttons, sapphire, glass, ceramic tiles, aluminum plates, signs and other metal materials, non-metallic materials, etc. For the purple laser marking machine using cold processing , These are all his majors, and the industries targeted are electronic communications, electrical and electrical, instrumentation, precision hardware, watches, glasses, accessories, ceramics and other industries.

(4) For non-metal processing industries such as clothing, leather, craft gifts, packaging, advertising, wood, textiles, plastics, signs, electronic communications, watches, glasses, printing, decoration, etc., marking can be realized. The processing of wood products, cloth, leather, plexiglass, epoxy resin, acrylic, unsaturated resin and other non-metallic materials has good results.

(5) The application in the food industry currently mainly refers to the use of lasers to make various information marks on the surface of food, such as: patterns, two-dimensional codes, etc. The advantages are no consumables, finer and clearer printing effect, higher resolution, and failure Low rate, clean and pollution-free.

(6) Direct packaging industry. We all know that the laser marking machine is also the laser inkjet printer, which is the food and beverage packaging, wine bottle cap and cigarette case packaging, medicine box/bottle packaging… No matter what the material is, these need to be marked and identified on the material. The product is marked by a laser marking machine, that is, the production date, batch number, QR code, etc. of the product are clearly marked on the material.

- Application of laser engraving machine:

(1) Plaques, signs and signs The ever-changing construction of urban public facilities, the renovation of streets, modern residential quarters, hotels, and office buildings have generated a lot of demand for signs and guidance systems that meet international standards, among which engraved plaques , signs and signs occupy a considerable part. In order to establish a good corporate image and perfect internal management, powerful companies have also replaced the company’s plaques with engraved ones, and made chest badges and department badges in the form of engraving. It has already become a fashion trend.

(2) Architectural models, mechanical models, vehicle models, and ship models are the oldest design tools, and modern society has given models more novel meanings and wider uses. It is no exaggeration to say that models are industrial model. The performance and display of machinery, vehicles, ships, architectural design schemes, and the sale of commercial housing are all inseparable from models. The models themselves also have independent activities and meanings such as competitions, commemorations and collections. At present, the engraving machine, which makes the model making more beautiful and faster, has become the best helper for making models in all walks of life.

(3) Arts and crafts, gifts, souvenirs More and more medals, certificates, souvenirs and advertising materials in conferences and tourism activities are popularly made by carving. Engraving on pens, leather goods, tableware, lighters, watches, bottle openers, key chains, trophies, award plates, imitation crystal ornaments, golf clubs, shotguns, rings, etc. Boxes, pendants, mirror frames, silverware and other items are given interesting carvings to meet people’s needs for emotional communication.

(4) Industrial processing The output of China’s building materials has already ranked first in the world, and it is developing rapidly in the direction of improving quality and improving varieties of colors. The engraving machine can easily and quickly create a large number of exquisite molds for gypsum ceilings, ceramic tiles, floor tiles and other building decoration materials, so that the value of decorative materials processed by this mold is doubled. In countries with developed manufacturing industries, the marking of parts surface, the production of instrument panels, and the production of various signs, identification plates, job number plates, and production flow charts necessary for enterprise standardization management are mostly completed by engraving machines. , According to foreign survey statistics, in developed industrial countries in Western Europe such as Germany and Switzerland, 2/3 of the engraving machines are used as machine tools in factories. China is becoming the “factory of the world”, and it is believed that engraving machines will enter one workshop after another in China.

(5) Plexiglass technology, Plexiglass processing Plexiglass is one of the most ideal engraving materials, no matter which of the five techniques of “cutting”, “milling”, “carving”, “carving” and “drilling” of the engraving machine is used Various processing methods, plexiglass has excellent machinability, and plexiglass has always been an ideal material for test equipment, models, POP advertising decorations, small ornaments, art lamps, craft gifts, souvenirs, etc., engraving machines and plexiglass This intimate combination of good tools and good materials will inevitably produce a variety of excellent products.

The difference between laser marking machine and laser engraving machine? The so-called laser marking machine refers to a device that uses a laser beam to permanently mark the surface of various substances. Laser engraving machine refers to an advanced equipment that uses lasers to engrave materials that need to be engraved. The common features of laser marking machine and laser engraving machine are all processed by laser, and they all belong to advertising equipment. Laser marking machines can be used not only in the advertising industry, but also in various packaging industries. Laser engraving machines can be used not only in the advertising industry, but also in various decoration, automobile industries, etc.

Leave a Reply

You must be logged in to post a comment.