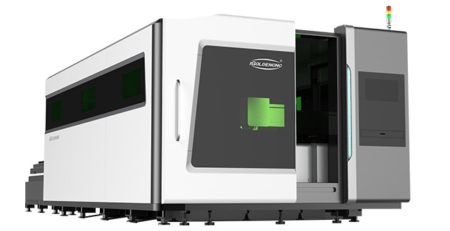

Sheet and tube Laser Cutting Machine

The dual-use fiber laser cutting machine can realize the cutting of two different materials on the same equipment. It can cut both metal plates and tubes (including square tubes, round tubes, channel steel, angle steel, etc.). One machine with multiple functions, high cost performance, professional pipe cutting control system, high precision, full function, easy to use, simple operation, suitable for comprehensive processing and manufacturing enterprises.

- Applicable tube types : Round tube, square tube, rectangular tube, oval tube, D-shaped steel ,T-shaped steel, H-shaped steel, channel steel, angle steel, etc.

- Applicable materials : Stainless steel, carbon steel, galvanized steel, copper, aluminum, brass, alloy, etc.

AUTO-FOCUS LASER CUTTING HEAD

The laser head has a built-in motor drive unit, and the focusing lens is driven by a linear mechanism to automatically change the position within 20mm. The user can set continuous focus through the program to complete the rapid perforation of thick plates and automatic cutting of plates of different thicknesses and materials. The compound lens group equipped with D28 integrates the light beam and optimizes the optical and water-cooled design so that the laser head can work stably for a long time.

The standard length is 3000mm/ 6000mm/ 9000mm lateral rotation axis device, which can process square tubes, round tubes, oval tubes, rectangular tube, irregular tube and other metal material tubes.

Clamp design: The electric clamp design is used on both sides, which can automatically adjust the center. The adjustable range of the diagonal is 20-220mm.

Automatic support installation: It adopts intelligent tube bracket design, which can solve the deformation problem during the cutting process of long tubes.

It can process both metal plates and metal pipes, one machine for two purposes, saving space and cost, and improving production efficiency.

iGR-FT tube laser cutting machine produces high quality parts in a variety of shapes and sizes. By using its fiber laser cutting technology, multiple processes can be combined into one machine. Since most parts require multiple processes, such as traditional sawing, drilling, machining, punching and engraving, iGR-FT tube fiber laser cutting machine can perform all of these processes on a single machine.

The laser tube cutting machine is equipped with a manual loader that presents the tube to the operator who must then place the tube into the machine and manually tighten the chuck. Combining all these processes into one machine saves time and cost when processing tubes in large batches yet the machines versatility allows the user to easily make prototypes or small batch production.

This tube laser cutter also utilizes high speed servos for quick and precise positioning which decreases the time for non-value added movements. These High speed servos in conjunction with the powerful fiber laser can decrease part cutting times and increase production allowing for a higher return on investment for the end user.

This laser tube cutter is also equipped with a full enclosure to ensure the operator is safe while the machine is active.

Leave a Reply

You must be logged in to post a comment.