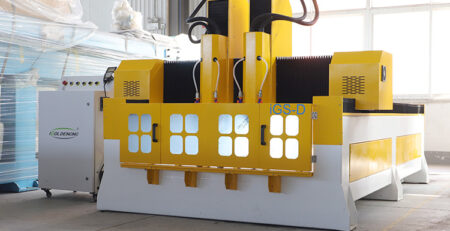

5 Axis CNC router machine for special-shaped processing

The 5 axis CNC engraving machine has the characteristics of high efficiency and high precision. It is specially used for processing complex curved workpieces. The workpiece can be clamped to complete complex processing requirements at one time, and can be adapted to the processing of modern molds, such as automobile parts and aircraft structural parts. The 5 axis CNC router machine has five axes and can perform link processing. Good at space surface processing, special-shaped processing, hollow processing, punching, oblique hole, oblique cutting and other processing methods. Next, we will introduce the 5 axis CNC router machine self-developed by IGOLDEN.

The advantages of the 5 axis CNC router machine:

- The head rotates from 0°to 360°, and the head tilts from 0°to ±110°to ensure more functions.

- The Italian 10KW spindle is professionally applied to five-axis CNC milling machines; it has strong cutting ability and low noise, which can ensure the machine to work for a long time.

- Japan’s original Yaskawa servo motor and driver ensure higher strength and precision of the machine.

- Japanese THK 30mm linear guide rail and German rack, all well-known brands and high-quality choices, ensure the high performance and long life of the machine.

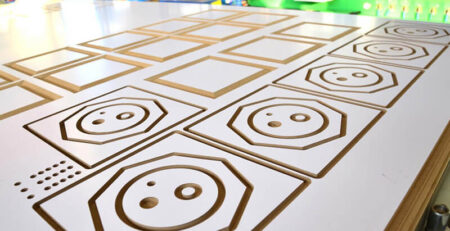

- It can be used not only for plane carving and cutting, but also for surface carving, arc milling, and surface processing of different objects (such as special-shaped artwork, curved doors or cabinet panels, etc.).

- Super heavy steel frame and gantry can achieve maximum straightness and rigidity. The whole machine is made of welded steel structure. After aging treatment, long-term use will not be deformed. In order to facilitate transportation and hoisting, the base and beam adopt a split structure

- The movable structure of the workbench is flexible to operate, ensuring high precision and low vibration.

- Disc type automatic tool changer, the tool magazine is fixed on the side of the gantry, and is always on the same horizontal line with the spindle, and the tool is automatically changed, which saves manual tool change time and is more efficient.

- Equipped with industrial cooler to cool the spindle, housing bearing wear and aging, and extend the service life of the machine tool.

Please note: add distilled or purified water, do not add tap water.

Applicable industries of 5 axis CNC router machine:

- Mould industry: wooden ship model, automobile model, aviation wooden model and many other wooden models.

- Foam industry: It can be carved and cut on any type of foam through 2D and 3D size processing. Processing effects: engraving, cutting, milling, drilling, embossing, shadowing, etc.

- Carving various large-scale non-metallic molds, especially suitable for any kind of foam (EPS) molds, wooden ship molds, wooden aviation molds and other wooden molds for 3D processing: cylindrical, square sculptures, etc.

- Wooden furniture industry: wave board, exquisite patterns, antique furniture, wooden doors, screens, sashes, composite doors, cupboard doors, interior doors, sofa legs, headboards, game cabinets, computer tables, sewing machine tables, instruments, etc.

- Ceramic bathroom industry: plaster, ceramics, marble cutting or prototyping.

The above is an introduction to the 5 axis CNC router machine. If you have other needs, you can leave us a message, and our staff will reply to you as soon as possible. I hope it helps you.

Leave a Reply

You must be logged in to post a comment.