Vacuum adsorption CNC woodworking engraving machine

What is a CNC engraving machine? This must have been our initial concern when we first heard about this CNC engraving machine. Jiabang CNC will introduce CNC engraving machines from the aspects of equipment, processing advantages, models, core components of machine tools, processing materials, and application industries. Because the more you know about the machine, the more you will choose and use CNC engraving machine equipment.

What is a CNC engraving machine?

What is a CNC engraving machine?

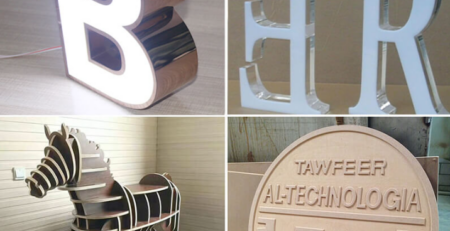

CNC engraving machines are often used to engrave a variety of products, such as wood, acrylic, PVC board, MDF, marble, rubber board, plastic, glass, foam, crystal, etc. It has the advantages of complete variety, wide application range, unique function, high processing precision, fast production efficiency and simple process.

Compared with traditional handicrafts, CNC engraving machine:

cut costs. Meet operational requirements without costly procurement and training. This CNC woodworking engraving machine can help individuals save 30% of the purchase cost, especially for MDF, wood cutting.

Wide range of applications. CNC woodworking engraving machine can be widely used in advertising industry, handicraft industry, mold industry, electronic equipment industry, construction industry, printing and product packaging market, woodworking industry, decoration industry, tombstone industry, etc.

Materials are widely used. CNC woodworking engraving machine can complete the processing of most non-metallic materials such as acrylic, PVC board, hibiscus board, two-color board, wood board, MDF, marble, fireproof board, rubber board, glass, crystal and so on.

high degree of automation. Compared with the previous conventional processing methods, the processing performance of CNC woodworking engraving machines has been improved by 50%, providing individuals with better income and profits.

wood processing project

Mainly used for processing various doors, windows, cabinets and other furniture decoration. In fact, CNC woodworking engraving machine can not only process wood, but also plastic, acrylic, aluminum, copper and other metals. Widely used in musical instrument industry, advertising industry, decoration industry, architectural model industry. In addition, it can be used for engraving, panel furniture, engraving, solid wood and milling. Here are which industries need CNC woodworking engraving machines.

Door

In the woodworking industry, CNC woodworking engraving machines are one of the most popular applications for carving cabinet doors. Wooden cabinet manufacturers buy CNC woodworking engraving machines, which are usually used for mass production to reduce costs and increase production. In addition, if equipped with multiple spindles, the CNC woodworking engraving machine can also process at the same time, saving time. At the same time, various tools can be used to process cabinet doors, drawers, dining tables, etc.

Chairs, Tables and Cylindrical Stair Armrest Sofa Legs

The advantage of CNC woodworking engraving machine is that it not only saves production time, but also is no longer limited to mold plane engraving. CNC woodworking engraving machine is equipped with rotating shaft, intelligent software and computer software to design digital curve model. The software supports 3D format, which can be modified on the computer according to the processing requirements of different customers. In our life, some Roman columns and columns in parks and office buildings are handled in this way.

Vacuum adsorption CNC woodworking engraving machine

CNC woodworking engraving machine is a highly intelligent and automated machine tool, not a traditional machine tool. As a result, users can handle different sculpting curve parameters that need to be designed to handle products such as chairs, sofa legs, and stair railings. CNC woodworking engraving machines are more innovative and intelligent, and can meet the customized needs of customers and produce personalized products.

Musical instrument production and processing industry

CNC woodworking engraving machines are now slowly being used in the musical instrument processing industry. A wood engraving machine equipped with a rotating shaft becomes a 3D engraving machine. You can operate the machine to engrave the three-dimensional surface of the instrument to complete the engraving of pattern shapes. This machine can choose high-quality brands, and the surface of the processed samples is smooth and delicate. Today, more and more manufacturers use CNC wood engraving machines to produce shell panels for guitars, cellos, and violins.

wood processing industry

CNC woodworking engraving machine can also be used for handicraft processing, such as craft photo frames, toy models, sporting goods, etc.

advertise

Because CNC woodworking engraving machine can be used to cut acrylic panels, aluminum-plastic panels, decorative materials and MDF, etc. They are also widely used in today’s advertising industry, such as human-shaped signs, light signs, billboards, etc., users can design their own personalized patterns. In addition, CNC woodworking engraving machine can also be used in the EVA processing industry to cut and engrave EVA materials such as EVA materials, EPS, foam materials, such as EVA material packaging tools, express packaging foam, medical packaging, electronic products, etc.

The advantages of CNC woodworking engraving machine:

The high-strength integral casting bed, combined with the T-shaped structure aluminum profile table, is sturdy and durable, and the workpiece can be arbitrarily fixed without deformation for many years.

The breakpoint memory method is adopted to ensure that it can be processed in the event of an accident (broken tool) or the next day.

Adopt Taiwan original linear square rail, double row and four row ball slide block, large bearing capacity, stable operation and 10 times higher precision than ordinary guide rail.

The woodworking engraving machine can be programmed by itself, and some simple programs can be directly edited to test the performance of the equipment, or it can be transferred to advanced users according to special needs.

Leave a Reply

You must be logged in to post a comment.