Jidong pur edge banding machine model, automatic pur edge banding machine

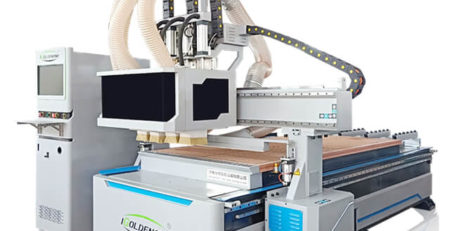

Jidong pur edge banding machine model, automatic pur edge banding machine is a relatively high-end equipment in automatic edge banding machines, which can achieve very good edge banding and welt work, fast edge banding speed, high processing quality, high quality . Is it because it has these advantages and is popular in the market, but the price is higher than other edge banding equipment, so that everyone can fully understand the reasons and advantages of this equipment’s high price? Next, Jiabang CNC will introduce to you.

In the panel furniture production enterprise, the edge banding machine is a very important equipment, so the edge banding machine is available from semi-automatic to fully automatic, and now profiling tracking is considered as a high-end pur edge banding machine. As long as the furniture factory has a pur edge banding machine, the products produced will definitely not be bad, so what are the advantages of pur? What kind of factory is suitable for use.

In the panel furniture production enterprise, the edge banding machine is a very important equipment, so the edge banding machine is available from semi-automatic to fully automatic, and now profiling tracking is considered as a high-end pur edge banding machine. As long as the furniture factory has a pur edge banding machine, the products produced will definitely not be bad, so what are the advantages of pur? What kind of factory is suitable for use.

The pur edge banding machine is mainly used for high-gloss panel and door panel manufacturers. Dealing with glue line issues and edge sealing is almost seamless.

This type of equipment includes pre-milling, double glue pot, gluing, edge sealing, tape cutting, six-turn edge pressing, single leading edge cutting, rough cutting edge, fine cutting edge, scraping edge, cleaning, separation, double polishing (baking ) ). light) and other optional features. If you don’t use some of these features, you can negotiate with the factory to reduce the allocation, or you can add the configuration you need, actually dual rail to make it faster.

At present, most enterprises have replaced equipment. With the update of current technology, laser edge banding machines will be launched one after another. It’s just that the price of the laser edge banding machine is too expensive at present, and it will be put into production slowly after the simplification in the later stage, so that most customers can use a good edge banding machine.

Function details of automatic double trimming machine:

Pre-milling: When the edge sealing surface of the plate is not flat, the edge can be milled first, and then the edge can be pressed together.

Adhesive edge: non-stick adhesive disc, sol uniform, cylinder controlled pressing roller, tape is better.

Front and rear: Through the structure of automatic mold tracking and high-frequency high-speed motor, the redundant edge strips at the front and rear are cut off to ensure that the section is flat and smooth.

Rough trimming: The rough trimming knife is a flat knife, which is used to seal the edge of the plate with excess edge-sealing material after trimming up and down, so that the trimmed plate is flat and smooth up and down.

Trimming: The trimming knife is oblique trimming, which is used to trim the upper and lower edges of the processed plate with the excess edge material after rough trimming, and at the same time form a natural transition between the plate and the plate. The edge band is curved.

Copy Tracking: contour trimming, chamfering effect trimming, and edge sealing effect more rounded and smooth.

Scraping: It is used to eliminate the ripple marks (knife marks left by the trimming knife and the rounded corners of the trimming) during the cutting process of the non-linear motion of the trimming edge, so that the edge sealing surface of the sheet is smoother and more tidy.

Polishing: Use a cotton buffing wheel to clean the polishing plate to remove excess gum and make it smoother.

Leave a Reply

You must be logged in to post a comment.