What You Must Know Before Buying A CNC Plasma Metal Cutting Machine

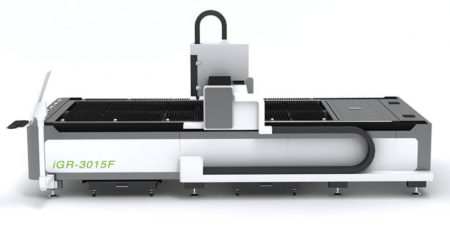

The cnc plasma metal cutting machine is a kind of thermal cutting equipment. Its working principle is to use the heat of the high-temperature plasma arc to locally melt the metal at the incision of the workpiece, and use the momentum of the high-speed plasma to remove the molten metal to form a processing method of the incision.

Plasma cutting uses compressed air as the working gas, high temperature and high speed plasma arc as the heat source, partially melts the metal to be cut, and at the same time blows the melted metal away with high-speed airflow to form a narrow slit. Plasma cutting has some similar advantages to laser cutting and is currently widely used in sheet metal processing and industrial production.

What You Must Know Before Buying a cnc plasma metal cutting machine

Machine quality

First and foremost, the number one thing to make sure of is that you’re getting a high quality machine. CNC plasma cutting tables (no matter the manufacturer) are expensive. Do your homework beforehand and make sure you’re getting the highest quality your budget will allow.

Materials

You’ll want to check on the quality of materials used in construction of the frame. Is it steel? Aluminum? Something else? Steel is stronger than aluminum, of course, so the steel machines will require less material and will be lighter, but will have the appearance of flimsiness. Aluminum machines will be bulkier, but will have the appearance of strength. Machines made of either material will have more than enough strength for even the biggest jobs.

Design

You’ll want to check on the quality of the table design. So many factors can affect the performance of the table, and the slightest variation in even the smallest factor can alter table performance. For example, if the gantry (the big heavy bar that slides up and down the length of the table) is too heavy, it makes the torch difficult to control with high speed and accuracy. A light-weight gantry, on the other hand, can produce amazingly accurate results at high speeds.

Also consider rolling surfaces. Sealed ways keep out more dust and grit, but they can’t keep out all of the inevitable plasma dust Eventually the dust will mix with the oil and create a gritty sludge that will chew up the parts. Because it’s sealed, you’ll have to replace the entire component. Unsealed parts, however, are much simpler. An unsealed roller on a simple way can be wiped completely clean in a second, and should a part need to be replaced, it can be accessed without replacing the entire component.

Motors

What sort of motors control the torch? Servo motors are widely recognized as superior to stepper motors. A servo motor can move to an infinite number of positions within its range of motion, and it provides feedback to the controller, telling the controller where it happens to be at the moment. A stepper motor has a finite number of positions it can move to and provides no feedback to the controller. Thus, it sometimes happens that the controller will tell the stepper motor to move a certain number of steps, but the controller has no way of knowing if the requested movement actually occurred.

If the torch hit a snag or otherwise didn’t move for some reason, the entire cut path will be offset from where the controller thinks it is. Of course, servo motors are more expensive than stepper motors. Just take care that your attempts at cost-cutting don’t hamper your ability to cut quality designs.

CNC plasma metal cutting machine have a system that can move the path of plasma torch by computer. IGOLDENCNC is the best gantry type CNC Plasma cutting machine manufacturer in India. Our plasma cutting machine are appreciable in the industrial field. Plasma cutting can cut easily the same and greater thicknesses of material than Fiber Laser Cutting machine.

Leave a Reply

You must be logged in to post a comment.