Which brand of five-axis machining center is good?

The five-axis machining center is of great help to improve the machining efficiency and shorten the machining process. At the same time, it is very helpful for high-precision machining. It plays an important role in the machining of parts. So how much do you know about this device? Don’t you understand? Next, Jiabang CNC will give you a detailed summary.

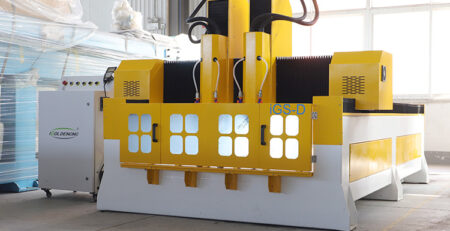

The five-axis machining center has the characteristics of high efficiency and high precision, and the complex machining can be completed in one clamping of the workpiece. It can adapt to the processing of modern molds such as auto parts and aircraft structural parts. There is a big difference between a five-axis machining center and a pentahedron machining center. Many people do not know this and mistake the pentahedron machining center for a five-axis machining center.

The five-axis machining center has the characteristics of high efficiency and high precision, and the complex machining can be completed in one clamping of the workpiece. It can adapt to the processing of modern molds such as auto parts and aircraft structural parts. There is a big difference between a five-axis machining center and a pentahedron machining center. Many people do not know this and mistake the pentahedron machining center for a five-axis machining center.

The five-axis machining center has five axes, X, Y, Z, A, and C. The x, y, z, a, and c axes constitute five-axis linkage processing. Good at space surface processing, special-shaped processing, hollow processing, punching, inclined hole processing. The pentahedron machining center is similar to the three-axis machining center, except that it can do five surfaces at the same time, but cannot do special-shaped machining, drilling inclined holes, cutting inclined surfaces, etc.

Five-axis machining centers are well-known in the market for their stable performance, durability and low failure rate.

Five-axis machining centers are not only used in civil industries such as wood mold manufacturing, bathroom decoration, automotive interior parts processing, mold processing, solid wood chairs, etc., but also widely used in aviation, aerospace, military, scientific research, precision instruments, high-precision medical equipment and other industries . A five-axis machining center is a high-tech means of making the impossible possible. All spatial surfaces and special-shaped machining can be realized. It can not only complete the mechanized processing tasks of complex workpieces, but also can quickly improve the processing efficiency and shorten the processing process.

Regarding the equipment of the five-axis machining center, the above content has been summarized in detail for you. From this, we learned that the equipment has the characteristics of high efficiency and high precision, and also has the advantages of stable performance, durability and low failure rate. If you need to buy equipment in this area, you can contact Jiabang CNC to provide you with a better solution.

Five-axis machining centers are good at space plane processing, special-shaped processing, hollow processing, punching, oblique drilling, chamfering, etc., and are widely used in aerospace, military scientific research, precision machinery and other fields, high-precision medical equipment, conventional manufacturing, etc. The five-axis machining center with automatic tool change function can easily complete the complete machining of complex parts such as milling, slotting, drilling, sawing, tenoning, tenoning, etc. Five-axis machining center accessories Jiabang CNC design adopts internationally renowned brands, which are more durable.

Advantages of five-axis machining centers

Maximum reliability

The reliability of five-axis machining centers has always been an important indicator that users care about most. The numerical control system will use higher integrated circuit chips, use large-scale or ultra-large-scale special-purpose and hybrid integrated circuits, increase the number of components, and improve reliability.

CNC programming automation

At present, the interactive automatic programming of CAD/CAM graphics has been widely used, which is a new trend in the development of five-axis machining centers.

Intelligent

Modern five-axis machining centers will introduce adaptive control technology to automatically adjust task parameters according to changes in cutting conditions, so as to maintain optimal task conditions during machining, thereby obtaining higher machining accuracy and smaller surface roughness. It can also improve the service life of the tool and the production efficiency of the equipment.

Control system miniaturization

The miniaturization of the numerical control system is conducive to the integration of electromechanical devices. At present, it is important to use ultra-large-scale integrated components, multi-layer printed circuit boards, and three-dimensional installation methods to achieve high-density installation of electronic components and reduce system footprint in a large range.

Multifunction

Various machining centers equipped with automatic tool changing mechanism (tool magazine capacity can reach more than 100) can simultaneously complete milling, boring, drilling, turning, reaming, tapping and other processes on the same machine tool. Modern five-axis machining centers also use multi-axis polyhedron cutting, that is, different cutting methods are simultaneously performed on different parts of a part.

Leave a Reply

You must be logged in to post a comment.