4 Axis CNC Foam Cutting Machine for Wooding

What is the 4 Axis CNC Foam Cutting Machine?

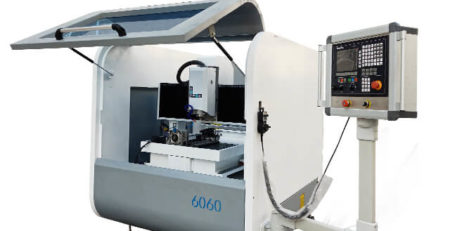

The split type polyfoam 3D 4 Axis CNC Foam Cutting Machine is a CNC carving machine designed for foam processors who are subject to transportation, site restrictions or format restrictions, and is mainly used in the aviation industry, woodworking industry, craft gifts, film and television. 3D sculptures such as props, building models, electronics, CAD/CAM industrial molds.

Mold industry

The wood CNC router plays an important role in the mold production process. The use of CNC engraving machine processing technology can not only ensure the accuracy of the mold, but also facilitate the convenient and efficient design and processing of the mold. Therefore, the engraving machine is the first choice processing equipment in the mold processing industry.

CNC equipment in the mold industry mainly reflects the engraving of various wood and foam. This processing has also been widely used in the woodworking industry, such as furniture embellishment, plane carving of large-area boards, carving of solid wood, mahogany and other furniture.

In addition, the engraving machine can also be used in precision mold industry, toy industry, crafts and other industries. It can be used to process copper electrodes, stamping molds, hot stamping molds, hardware molds, glue molds, rubber molds, etc. And it is also used in watch and eyewear accessories.

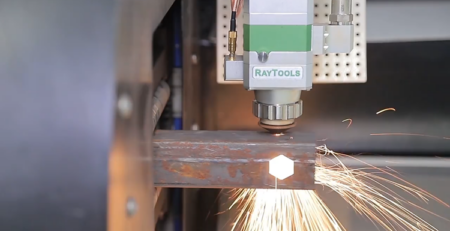

CNC Foam Cutters

CNC Foam Cutters are capable of cutting out some pretty cool shapes that would otherwise be extremely difficult to do. They do this by pulling a heated metal wire though a block of foam. Electrical current passing through the wire heats it up causing the foam to melt away, there is no dust and no mess to clean up.

Machine Features

- The lathe bed of the foam CNC router machine is welded with thicker square tube and is processed by high temperature tempering treatment and vibrating stress relief (VSR) to relief residual stress. The stability is excellent, not easy to be deformed. It has the property of good rigidity and heavy loading.

- CNC foam router machine adopts Hiwin high precision square guide rail, X and Y axes adopt rack and pinion transmission, fast working, high efficiency and low cost, Z axis adopts Germany-made ball screw, with high precision and longevity.

- Foam CNC mill adopts gantry movement,it can process any kinds of materials freely.

- Intelligent processing cross-border protection function can prevent mechanical impact caused by the improper design documents.

Leave a Reply

You must be logged in to post a comment.