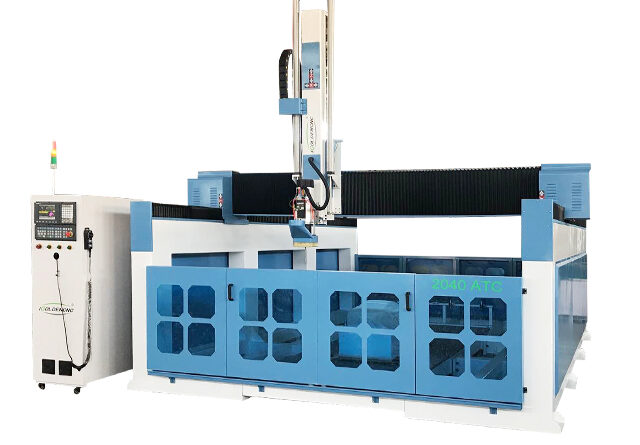

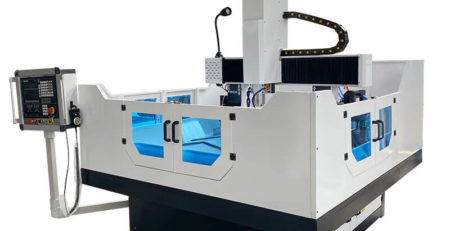

CNC foam model engraving machine

The CNC foam model engraving machine is a powerful tool for creating intricate and precise foam models. Its CNC technology, high precision, versatility, and efficient workflow make it a valuable asset in industries such as architecture, prototyping, film production, and packaging. By automating the foam carving process, it saves time and enables the production of complex and realistic foam models with ease.

Polylong foam engraving machine machining center is widely used in the production of various models, such as foam molds, automobile molds, train car molds, aviation molds, paraffin molds, etc., suitable for 3D milling, special-shaped cutting, drilling, chamfering, etc. It belongs to light cutting CNC machine tools. Styrofoam CNC machine tool is a CNC equipment professionally used for actual processing, with the characteristics of fast processing speed and stable operation. Foam CNC machine tools are also known as foam machining centers, foam milling, foam engraving machines, solid engraving machines, etc. So why is the foam engraving machine more and more favored by foam model manufacturers?

A CNC foam model engraving machine is a type of computer numerical control (CNC) machine that is specifically designed for the engraving of foam models. These machines use cutting tools to remove material from a foam block or sheet, creating a desired shape or design.

Judging from the user’s usage, this engraving machine has a long service life and can protect the interests of enterprises. Due to the low maintenance rate of the engraving machine, it can ensure the stability of production and help enterprises save maintenance costs, and the profits of enterprises will naturally increase.

Judging from the user’s usage, this engraving machine has a long service life and can protect the interests of enterprises. Due to the low maintenance rate of the engraving machine, it can ensure the stability of production and help enterprises save maintenance costs, and the profits of enterprises will naturally increase.

Speed: Compared with other engraving machines on the market, the foam model engraving machine engraves faster. In this way, the work efficiency of the enterprise can be guaranteed to a certain extent. In the Internet era, as long as the product is good enough, there is no need to worry about not being able to sell it. Therefore, in order to obtain higher profits, enterprises need to improve production efficiency. Therefore, the engraving speed of the engraving machine is fast enough, and the output of the enterprise will increase.

Accuracy: Compared with the ordinary engraving machine, the foam model engraving machine can be more precise in engraving, which can ensure the precise control in the production process and the quality of the products produced by the enterprise. Now, if companies want to survive in the market, they need to improve the quality of their products in order to gain more consumer recognition.

To sum up, the advantages of the foam model engraving machine are still great, and you will never suffer from this equipment. In the case of ensuring work efficiency and stability, the company’s product quality will definitely get better and better.

Functional characteristics of foam engraving machine: low price, high production efficiency, high precision, advanced technology, convenient operation, reasonable design, small footprint, etc. The characteristics of machining centers are widely used in various industries.

Foam engraving machine, the spindle can swing 180 degrees for three-dimensional processing.

The new generation (optional) handwheel operating system has good compatibility and stability.

Foam heavy-duty bed, no deformation during processing, good bearing capacity, stable and durable.

Equipped with rotating spindle, chuck 200mm length 5000, wide processing range.

Uses: EPS polystyrene foam CNC machine tools have been used to process non-metallic material molds such as EPS, casting wood molds, automotive interiors, engineering plastics;

The foam engraving machine adopts the international leading numerical control system, with high processing precision and high speed. Widened linear guide, self-lubricating block. When engraving, the force in all directions is equal, which ensures the mechanical precision and strength. The main shaft, line rail, and ball screw are all equipped with dust-proof blowing devices, which can prevent foam dust from entering the screw, line rail and main shaft. The line rail and lead screw are equipped with automatic lubricating device, which can effectively remove foam dust and avoid damage. The electric control cabinet can effectively dissipate heat and is suitable for long-term work.

Leave a Reply

You must be logged in to post a comment.