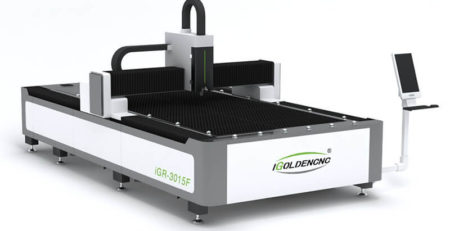

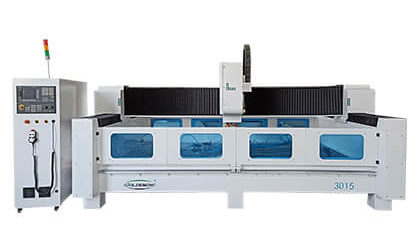

Automatic Fiber Laser Welding Machine

What is the Automatic Fiber Laser Welding Machine?

iGWL-AW series Automatic Fiber Laser Welding Machine is the new generation of safe, high efficiency, energy saving, environment-friendly metal laser welding equipment, using handheld swing welding head, infrared ray positioning, touch screen and button control, combined with the advanced integrated control system, the precision CNC fiber laser welding machine is assembled. The heating area is small during welding, and it will not cause deformation, blackening, and traces on the back of the workpiece.

Welding Head Features

1.The swaying welding head has a strong advantage in high-reflective material welding,wide range of application,it is very cost effective;

2.The welding head adopts motor-driven X- and Y-axis vibrating lenses, it has various swing modes and able to work on irregular shapes, larger welding spot and other processing parameters setting can improve markedly in welding quality;

3.The internal structure of the welding head is completely sealed to avoid dust contamination of the optical part;

4.Equipped with air curtain components to reduce contamination of dust and splash residues.

5.The protective lens has a drawer structure and is easy to replace. Can be equipped with various QBH connector laser sources.

Product description

★Automated laser welding machine can easily realize tailor welding, stitch welding and seam welding of various lengths and positions. Especially in the welding of thin stainless steel plates, iron plates, aluminum plates and other metal materials, it has the characteristics of fast welding speed, good surface effect, large penetration depth, and small heat-affected area.

★Cooperating with fixture and automatic programming control, it can realize batch fast/consistent welding requirements of similar products.

★ The welding is flexible and easy to operate. In addition to repairing large molds, large machines can also achieve long-distance welding, which can be welded without disassembling the product.

★ It has the advantages of simple operation, beautiful welding seam, fast welding speed, and no consumables. It can perfectly replace traditional argon arc welding, electric welding and other processes for welding thin stainless steel plates, iron plates,galvanized plates and other metal materials.

Laser Welding Features

- Fast welding speed, no consumables, no color change/less color change, no need for later polishing.

- The interaction of professional laser control system is enhanced, the accuracy of welding path is controllable, and the welding seam is formed well.

- Use infrared positioning to verify the position of the welding head and verify the position during the welding process. The welding position is more accurate, the welding seam is smooth and beautiful, and it is easy to grind and polish. There is no need to handle or only simple processing procedures after welding;

- 360-degree micro-welding without dead angles, after the laser beam is focused, the spot is small, the power density is high, and the positioning accuracy is high. It can be used for group welding of small and micro-sized workpieces to realize automated mass production;

- The laser welding depth is large, the weld seam is firm, the width is small, the heat-affected zone is small, the deformation is small, and the welding speed is fast. It can realize complex welding between some dissimilar materials;

- The welding seam is of high quality and no porosity, which can reduce and optimize the base metal impurities, and the structure can be refined after welding, and the weld seam strength and toughness are at least equivalent to or even more than the base metal;

- Stable output to ensure welding consistency. Most continuous laser welding are high-power lasers with a power above 500 watts. Generally, this laser should be used for plates above 1 mm. There are also some low-power continuous lasers with power between tens to hundreds of watts. They are used more in plastic welding and laser brazing industries.

Application Field

Continuous fiber laser welding machine is suitable for various kind of metal workpiece welding, it is versatile and suitable for the welding of metal connectors, mobile phone accessories (medium plate, nut), power battery, hardware, kitchen and bathroom electrical equipment, automotive parts structural parts, medical equipment, precision parts etc. It is mainly used for continuous welding of various metal sheets like copper, aluminum, titanium, stainless steel, low carbon steel, etc.

Leave a Reply

You must be logged in to post a comment.