CABINET MAKING WITH A CNC Machine Cabinetmaking

Today’s competitive cabinetmaking landscape demands that every cabinet maker embrace technology and automation. An excellent way to achieve this is by adopting a CNC Router.

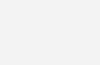

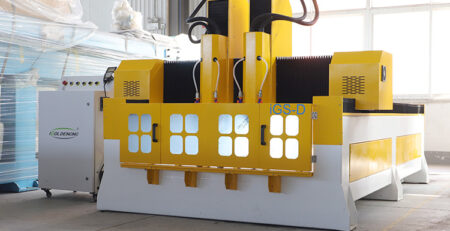

This CNC router is a high-speed, automatic load/unload, heavy-duty CNC routing system for nested based feed through machining. This CNC machine is used majorly in the production of cabinets, closets, and custom furniture.

This CNC router is a high-speed, automatic load/unload, heavy-duty CNC routing system for nested based feed through machining. This CNC machine is used majorly in the production of cabinets, closets, and custom furniture.

As an industry leader, CAMaster makes it easy for you to embrace CNC cabinet making through its variety of first-rate affordable CNC routers.

The Perks of CNC Machine Cabinetmaking

Increased production: CNC routers increase production throughput while minimizing material handling. A CNC router can drill shelf pin holes, cut rabbets and dados, and profile-cut the completed panel.

Accuracy: With repeatability of just 1/1000th of an inch, you get an accurate cut every single time

Diversification: CNC routers diversify your portfolio to include intricate 2D and 3D designs which increases your competitive edge.

Improved resource allocation: With the operation of CNC routers controlled by computers, machine operators become free for jobs that require human judgment and creativity, like design work.

Reduced waste: CNC routers produce consistent parts and minimize the need to scrap defective pieces.

Experience the CNC Cabinet Making Difference with a CNC Routers have made the manufacturing of doors, countertops, shelves, drawers, and drawer fronts available to small, mid-size, and large shops alike.

Our CNC routers are designed for cutting an array of styles and shapes from both soft and hardwoods, chipboard, melamine, MDF, and any other type of wood you might have in mind as well as plastics.

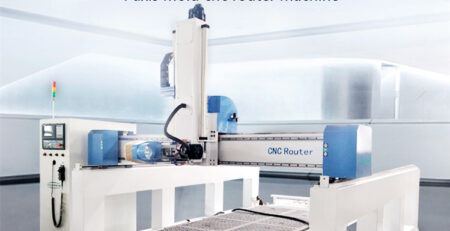

Double workbench, equipped with 9KW Italy aircooling spindle. More than 80 pcs board be done per day.

Drill bank fits series drilling size to accomplish different holes.

The software is with layout optimization.

With auto loading and unloading system, could semi- automatically load the sheet to the working table and push the processing table plate after it is finished, which is convenient for the operator to take the material, and saves time, and the efficiency is greatly improved.

APPLICATION

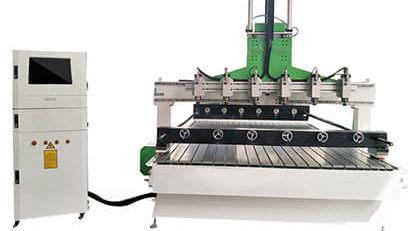

This full-automatic Intelligent CNC Router for Cabinet closet door furniture production has multi-functions of carving, engraving, milling, slotting, grooving, cutting, chamfer edge.

Full automatic Intelligent CNC Router Machine is mainly used in the furniture making industry, especially cabinet closet and door industries.

The Frame or frameless cabinet construction

Entertainment units

Kitchen cabinets, islands and peninsulas

Closets: Walk-ins, Reach-ins, Entries, Pantries

Angled and radius cabinets and countertops

Vanities

Bookcases

Home office workstations

Fine custom cabinetry… and much more

Contact us today to find the right CNC router solution for your cabinetmaking needs.

Leave a Reply

You must be logged in to post a comment.