Carved CNC Wood Working Machine Fast Method

Check the use of forceps or sculpture head is the wrong card at the same time, CNC router or card pliers head wear can lead to dislocation of carved objects. Pliers or chuck if tight contact with the head carved objects carved objects can lead to instant pop-up.

For those irregular shaped objects carved on the surface appear to have been fixed very tight, and when under pressure will be back and forth. At this time, you can try some scrap mat below the object to increase the friction. The other is to retain items comes with the packaging, although the object is irregular, but brought its own packaging may be very regular, and easy to be fixed, plus a small section of tape, very irregularly shaped objects easily be fixed. Or trial tools fixed the site of its rules, and give up its irregular part.

For those irregular shaped objects carved on the surface appear to have been fixed very tight, and when under pressure will be back and forth. At this time, you can try some scrap mat below the object to increase the friction. The other is to retain items comes with the packaging, although the object is irregular, but brought its own packaging may be very regular, and easy to be fixed, plus a small section of tape, very irregularly shaped objects easily be fixed. Or trial tools fixed the site of its rules, and give up its irregular part.

Carved objects have suffered under the pressure if large, consider whether you have to use the nose cone of the knife, if the diamond blade engraving machine moves in the process of carving the pressure is too large, the tool will cause the pressure side is carved objects move. If you use an incorrect diamond knife, can cause the same problem. A 90 or 100 degrees diamond knife, carving material in depth, and makes the material being carved in the process of moving.

The cnc wood working machine is often equipped with a multi-purpose pliers or the card first, but they are also of iron, so easy to be carved or damage to property in the process of carving in the fall, then use some rubber or rubber cap tubes used for carved objects fixed helpful.

For engraving plastic patterns can be carved Share tape material attached to the back side of adhesive tape and then sprayed with liquid glue,

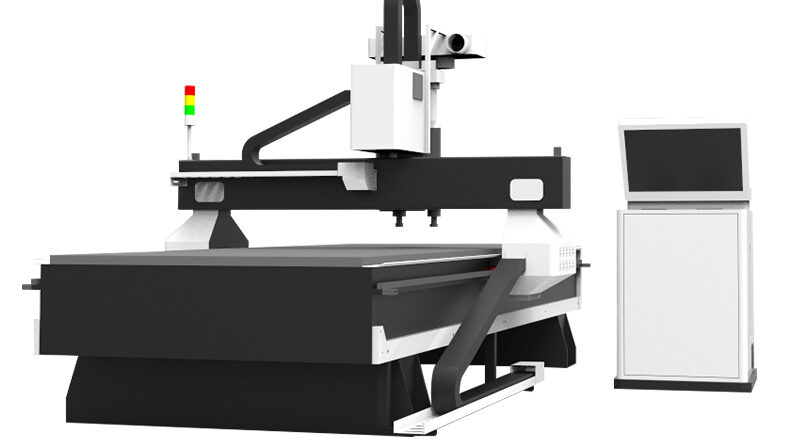

The top benefits of using a wood carving router machine are written below so that you can understand that this machine has the potential to transform your company’s operations completely and provide substantial advantages.

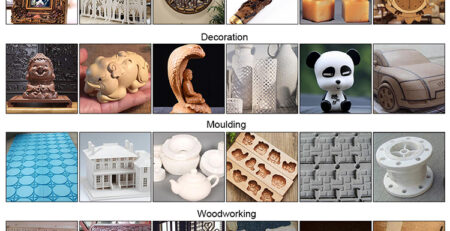

1.Versatile: A best wood for cnc carving can work on a variety of materials with equal ease.Some models may include additional features and accessories (such as automatic knife changer).Accelerate the production process.

- High productivity and scalability: Once the design specifications and parameters have been set on the machine, it starts to perform tasks consistently and pays the price for flexible scalability.

- Low maintenance: Due to the automation of digital machines, they update themselves automatically from time to time, thus simplifying the work process.They don’t require regular service.The only thing you need to change from time to time is the cutting tool.Regular light cleaning will only improve the quality of work.None of this requires a call to a professional, which in turn minimizes overhead.

- Minimum labor requirements: Several operators are required to perform production operations.The whole task can be accomplished by professional programmers and skilled operators, while in manual machines, the operator of each machine and the supervisor of management operations are required.

- 24-hour endurance: nc engraving machine can work continuously.It can be delivered 24 hours a day unless repairs or necessary repairs are required.

- Safe environment guarantee: CNC engraving machine provides a safer material cutting environment.Operators engaged in maintaining the proper functioning of the machine do not have to disturb themselves with sharp tools and tools, as is the case with traditional cutting methods.You can finish the work from a distance

The advantages of owning your individual hardwood CNC router are endless. Computer-controlled routers allow woodworkers to create complex designs, custom-made components or designs for mass production within the comfort of their working space at home.

Leave a Reply

You must be logged in to post a comment.