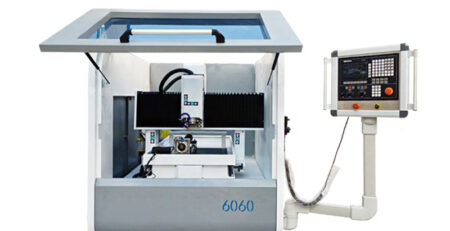

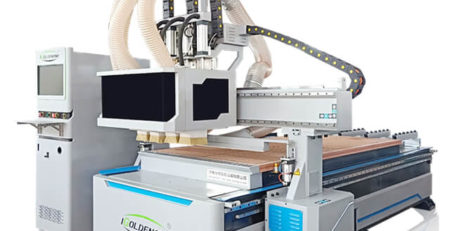

CCD automatic edge inspection laser engraving machine

With the hot sale of flat-panel laser engraving machines, the CCD edge patrol automatic engraving machine is very popular, especially the CCD edge patrol automatic laser engraving machine is particularly popular. + Integrated tube sheet metal welding assembly or cast iron structure + CNC gantry milling + modular design.

There are three types of CCD automatic edge inspection laser engraving machine platforms: blade platform, honeycomb platform and independent electronically controlled lifting platform, which can be selected according to their own needs.

The features of these three platforms are as follows:

The features of these three platforms are as follows:

Blade deck: The contact area between the blade platform and the material can be minimized, and the density of the blade can be adjusted according to the size of the material. This platform is suitable for processing acrylic and other plates, reducing the contact area between the material and the platform, solving the diffuse reflection generated by the laser hitting the platform after cutting the material, and leaving traces at the bottom of the material to obtain the best cutting effect.

Honeycomb platform: The honeycomb platform adopts high-quality honeycomb iron pick, which has high strength and long service life.

The honeycomb platform is suitable for processing soft materials such as leather, fabric, and paper products. The corresponding suction device can suck out flat materials to solve uneven problems such as bulging and warping of soft materials.

Electronically controlled independent lifting platform: integrated design structure, convenient lifting, lifting platform is used for processing thick workpieces. Standard requires cylindrical engraving and spinner.

Application of CCD automatic edge patrol laser engraving machine:

- Applicable materials: cutting, drawing and engraving of acrylic, plexiglass, wood, MDF?, sandwich panel, cardboard, leather, fabric, felt, fleece products, plastic sheets, film products, sheets and other materials; marble, crystal , tangent and engraving applications (not cuttable) for materials such as glass, tile, etc.

- Scope of application: generally used in advertising products, handicrafts, model handicrafts, fabrics, leather products, clothing design and cutting, gift crafts, wooden toys, exhibits, decoration and other industries.

Environmental protection CCD automatic edge patrol laser engraving machine requirements:

- Good grounding protection: the grounding wire eliminates static interference. 220V power supply.

- Stable power supply network: The voltage is relatively stable, and a voltage stabilizer is provided if necessary.

- Computer: Install Windows XP or win7 system.

Computer viruses may interfere with the control signals of the machine, and from a technical point of view, it is not recommended that the computer on which the user controls the device be connected to the Internet. Antivirus software must be installed on the computer. Computer configuration, requirements are not high. Usually the memory is not less than 128MB, the hard disk is not less than 40GB, the power supply of the computer switching power supply is stable, and the USB interface is stable and reliable.

Strong lightning can interfere with or damage the machine.

The ambient humidity is not more than 60%.

Professionals who must be trained to operate the equipment.

Advantages of CCD edge patrol automatic laser engraving machine:

Wide range: CO2 lasers can engrave and cut almost all non-metallic materials. And it’s cheap!

Safe and reliable: Non-contact processing does not cause mechanical extrusion or mechanical stress to the material. No “knife marks”, no damage to the surface of the workpiece, no deformation of the material;

Precise and meticulous: the machining accuracy can reach 0.02mm;

Economical and environmentally friendly: the diameter of the beam and spot is small, generally less than 0.5mm, and the cutting process is safe and hygienic;

Consistent effect: Ensure that the treatment effect of the same batch is exactly the same.

High-speed and fast: Engraving and cutting can be performed instantly and ate speed according to computer-generated patterns.

Low cost: Not limited by the number of processing, laser processing is cheaper for small batch processing services.

Leave a Reply

You must be logged in to post a comment.