Cabinet Side Hole Drilling Machine_CNC Wood Drilling Machine

The Side CNC Boring Machine for Wood Furniture Making, or side drilling machine is a practical numerical control equipment for plate furniture. It is mainly used to solve the problem that the CNC nesting machine cannot punch or boring side holes, and the precision of ordinary pneumatic row drills is not high, and needs repeated positioning.It is suitable for processing many kinds of board materials such as density board, particleboard, artificial board, solid wood board, plexiglass, PVC board, ABS board for board furniture, whole cabinet, wardrobe, customized furniture, office furniture that need to be punched.

CNC wood drilling machine features:

1. Dual servo system, Y axis servo drive laser sensor scanning hole, Z axis servo drive tool drilling and grooving.

The professional side hole drilling control system has high precision of repeated drilling.

2. It is not affected by the color of the plate, and the plate of 15mm to 25mm does not need to adjust the laser.

3. Fast running speed, air speed of 50 m/min, scanning speed of 40 m/min, drilling speed of 40 m/min.

4. Scanning mode, which can connect with many kinds of wardrobe and cabinet software on the market. After setting the parameters, do not need to sweep the code gun sweep the code gun. Reduce workload and improve processing efficiency.

Wood CNC boring machine for side holes, Side drilling machine for woodworking

The side drlling machine, or Wood CNC boring machine for side holes is an economical and practical horizontal drilling equipment. With the CNC cutting machine, it can form an economical panel furniture CNC production line. And widely used in the production process of various panel furniture. Compared with the traditional sliding table saw and row drill. The side hole machine adopts the gantry structure, the guide rail supporting surface is stable, the rack transmission method, the transmission is stable, and the long-term high-speed operation is not deformed or trembling. Therefore, it has the characteristics of high drilling precision and fast drilling speed.

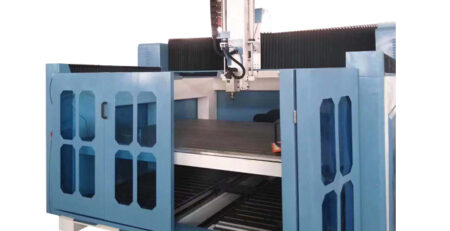

Six-side CNC drilling machine for woodworking

The six-sided CNC drilling machine is fully automatic drilling equipment. One-time positioning can realize the drilling requirements on all sides of the work piece and the grooving on both sides. It has processing advantages such as high precision and fast speed. Moreover, it is indispensable equipment for the production of custom panel furniture. Especially for small and medium-sized custom furniture manufacturers who want to increase their output, a CNC six-sided drilling equipment with a CNC cutting machine is definitely your best choice. Compared with the punching effect achieved by the CNC nesting machine and the side hole drilling machine. The use of a six-sided drilling machine can not only save labor more. And it has more advantages in processing accuracy and processing efficiency. Therefore, CNC six-sided drill is an indispensable CNC equipment for customized furniture manufacturers.

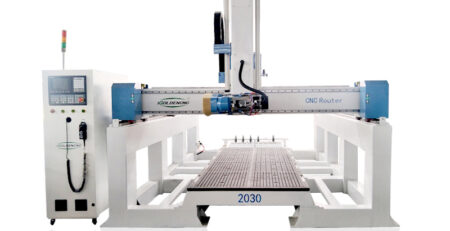

CNC nesting machine with row drill

The CNC drilling and cutting machine is a special machine for cutting and drilling of customized panel furniture. Compared with traditional sliding table saws and electronic cutting saws, the CNC drilling cutting machine can get rid of the traditional cutting mode relying on labor. It can also realize the vertical punching function while cutting the material. By combining with dedicated production design software, intelligent production is truly realized.

Why we need wood CNC drilling machine?

Wood CNC drilling machine is a better choice than hand drill machine, safe, efficient, precise. The application of the CNC drilling machine not only reduces the user’s production cost but also greatly improves the user’s production efficiency. Therefore, it is favored by more and more domestic and foreign users. Especially for users of the furniture production line, the production process has been optimized to a large extent, and it is indeed the best CNC drilling machine choice. In furniture production, the CNC machinery includes CNC nesting machine with multi-head drill, side drilling machine, and six-sided drilling machine. The drilling effect and drilling efficiency achieved by different drilling machines are quite different.

Leave a Reply

You must be logged in to post a comment.