How to prevent the failure of Four Head woodworking CNC engraving machine

With the advent of modern custom furniture, more and more CNC engraving machines have attracted people’s attention, but some failures will inevitably occur in daily use. What should we do to prevent CNC engraving machine from malfunctioning?

Inspection and cleaning of mechanical parts of CNC engraving machine

- Regularly clean the industrial control box.

- Regularly clean the screws to prevent foreign objects from sticking to the screws. The screw is very important in the equipment, it determines the precision of the machine, and also plays an important role in the transmission process.

- After the engraving work is completed, the desktop should be cleaned in time to provide convenience for the next step of the CNC engraving machine.

- Clean up the material debris on the guide rail and beside the guide rail to prevent the machine from jamming due to debris interference during work.

How to prevent the failure of Four Head woodworking CNC engraving machine

How to prevent the failure of Four Head woodworking CNC engraving machine

Treatment of oil pollution and waste oil in CNC engraving

When the CNC engraving machine is repaired, lubricating oil should be added in time. It will slowly move back and forth after refueling. CAD drawings ensure that lubricant can be added evenly to rails and screws.

After the machine is not used for a long time, use a cloth (without depilation) to clean the grease, waste oil and material debris on the guide rails and screws to ensure the flexibility of the operation of the components.

The above methods are the troubleshooting methods of CNC engraving machine organized by Jiabang CNC for you, I hope to help you.

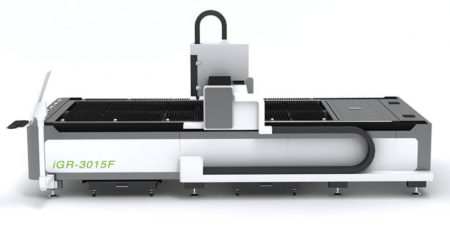

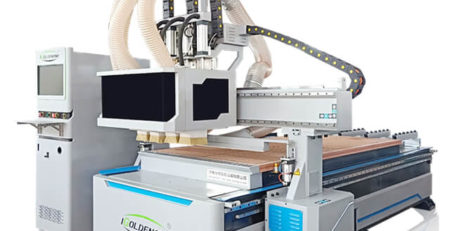

Recommended equipment: independent four-head woodworking engraving machine

Four-head woodworking engraving machine, as the name suggests, is a four-head woodworking engraving machine, that is, four heads can be processed at the same time or used alone, which is four times more efficient than a single head. Compared with the ordinary woodworking engraving machine, the independent four-head woodworking CNC engraving machine has three more independent processing spindles, which can be processed on one sheet at the same time. For mass production, the independent four-head woodworking CNC engraving machine is also suitable for the engraving of door panels, coffins and other processes. Widely used in solid wood and composite doors, cabinet doors, large-area plate plane carving, solid wood carving and milling, panel furniture carving, antique mahogany furniture carving, solid wood art mural carving and other industries.

How to prevent the failure of CNC engraving machine

Features:

- The steel structure of the high-speed woodworking engraving machine body is welded with thick-walled steel pipes, which are treated by vibration and aging, which is durable and not easy to deform.

- Using German ball screw, imported linear guide, high precision and durability.

- Strong software compatibility, compatible with type3/artcam/Wentai and other CAD/CAM design and production software.

- Using the USB interface mode DSP handle operating system, it can work completely offline, does not occupy computer resources, and is more convenient to operate.

- The design is more user-friendly, and it can be handy whether cutting vigorously or pecking carefully.

Leave a Reply

You must be logged in to post a comment.