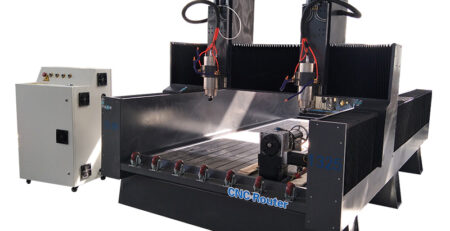

Best Metal CNC Machine for Small Business

A small laser cutting machine for metal is a device designed for cutting metals with a high degree of accuracy and precision. These machines use a laser beam to cut through the metal, rather than a traditional cutting tool. They are typically used in small businesses or workshops where space is limited, and are ideal for cutting intricate designs or shapes out of metal.

Small Laser Cutting Machine for metal

There are various small laser cutting machines available in the market that are suitable for metal cutting. When looking for such a machine, consider factors like cutting area, laser power, cutting speed, and the thickness of the material you intend to cut. Here are a few popular models to consider:

Please note that some of these machines may have limitations when cutting metal, such as requiring additional assist gases like oxygen or nitrogen, or having a limited thickness that can be cut. Be sure to check the manufacturer’s recommendations and user reviews to ensure the machine meets your specific needs. Prices may vary, so shop around for the best deal.

| Technical Parameters | |

| Processing format | 600*500mm |

| Countertop load-bearing | 60KG |

| Machine weight | 800KG |

| Z-axis travel | 80mm |

| Max. linkage speed | 50m/min |

| Max. acceleration | 0.6G |

| positioning accuracy | 0.03mm |

| Repeat positioning accuracy | 0.02mm |

| Machine size | 1250mm(L)*1150mm(W)*2050mm(H) |

| Configuration checklist | |

| Control System | Cypcut / Ncstudio / Taytools /JCZ (optional) |

| Laser | MAX |

| Motor | Fuji Electric Japan |

| Cutting head | Taytools |

| Cooling method | MingPin |

When looking for a small laser cutting machine for metal, it’s important to consider the following factors:

- Cutting power: The power of the laser determines how thick of a material it can cut. If you plan to cut thicker metal, you will need a machine with more cutting power.

- Cutting area: The size of the cutting area determines the maximum size of the metal that can be cut. Make sure to choose a machine that has a large enough cutting area for your needs.

- Ease of use: Some machines are easier to use than others. Look for a machine with user-friendly software and controls.

- Cost: Laser cutting machines can be expensive, so it’s important to consider your budget when choosing a machine.

When choosing a small laser cutting machine for metal, it’s important to consider factors such as the size of the machine, the power of the laser tube, the thickness of metal that can be cut, and the overall cost. It’s also important to ensure that the machine you choose is compatible with the software you plan to use and that you have the necessary training and support to operate it effectively.

Leave a Reply

You must be logged in to post a comment.