Multi-purpose and Choice of Plasma Machine

Multi-purpose and Choice of Plasma Machine

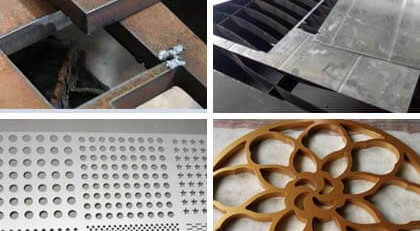

A plasma machine, also known as a plasma cutter, is a tool used for cutting electrically conductive materials. It creates a high-velocity jet of ionized gas, called plasma, to melt and remove metal. This results in clean and precise cuts. Plasma machines are used in industries such as metal fabrication, automotive repair, and construction. They offer advantages like fast cutting speeds, high precision, and the ability to cut through various materials. They come in different sizes and power capacities to suit different cutting needs.

There are also many types of plasma cutting machines. How to make a choice of plasma machine? CNC plasma tube cutting machine is used to cut iron round pipes, aluminum round pipes, galvanized round pipes, stainless steel round pipes, etc. The CNC plasma cutting machine can cut carbon steel for advertising signs, decoration, blacksmith gardens, automobiles, shipbuilding accessories, etc.

If you want a machine that can cut a variety of materials and metals, such as stainless steel, copper, aluminum, titanium, etc., please consider using our CNC plasma cutting machine. If you mainly cut thin steel plates and the smoothness of the cutting edge is relatively high, please consider using a laser CNC cutting machine. If you mainly cut carbon steel and don’t pay much attention to the cutting edge, it is recommended that you choose a CNC flame cutting machine or CNC plasma cutting machine with flame cutting.

We provides many types of CNC plasma machines for different metal cutting. CNC plasma cutting machine is welcomed by users for its advantages of high precision, high speed and high efficiency. To learn more before purchasing, please contact us online or via email.

Ralated Products

Ralated Projects

Plasma machines are popular in industrial and manufacturing settings, as they offer fast and precise cutting capabilities. They are often used in metal fabrication shops, automotive repair facilities, and construction sites to cut and shape metals for a variety of applications. One of the benefits of using a plasma machine is that it can cut through thick metals quickly and cleanly, without the need for pre-drilling or other preparation. This can save time and reduce labor costs, making plasma machines a cost-effective option for many businesses.

Leave a Reply

You must be logged in to post a comment.