Making Furniture With CNC Router

The advanced nature of the furniture production industry can be reflected in Europe and the United States, that is, customized orders can achieve large-scale production. That is to say, in catering to the needs of customers, using a combination of software and automation to form mass production, so as to realize production automation and process, in order to reduce labor costs and improve production capacity. How do domestic enterprises purchase furniture production equipment? Should hold forward-looking thinking, choose the products of furniture equipment manufacturers with corresponding technology and service strength, and carry out the production layout of panel furniture, namely 3+1 panel furniture production line: CNC cutting machine, edge banding machine, side hole machine (PTP) Machining center or five-sided drilling and six-sided drilling) + software.

Panel furniture production line layout

one. Cutting equipment: advanced cutting equipment is divided into two categories (1) electronic cutting saw (2) CNC cutting machine

At present, most small and medium-sized enterprises choose to use sliding table saws. The disadvantages of single sliding table saws are “three lows and two highs”: low processing efficiency, low processing accuracy, low safety factor, high work intensity, and high per capita wages.

Based on this situation, what is the significance of the choice of automatic cutting equipment as a problem. Electronic cutting saws and CNC cutting machines have their own advantages. The former is suitable for batch standardized operations, and the latter is suitable for batch customized processing and production.

- Electronic cutting saw: suitable for large-scale batch standardization. If the product type is one, the electronic cutting saw can be used for rapid cutting.

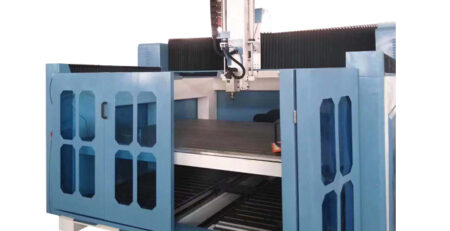

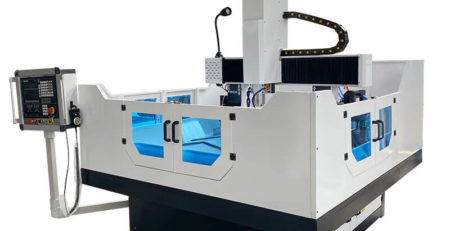

- CNC cutting machine: CNC machining center is particularly suitable for flexible customization of processing requirements, with high efficiency. In fact, electronic cutting saws rarely appear in the American furniture and equipment exhibitions, and CNC cutting machines are used for cutting materials without exception. At Ouzhao exhibition, CNC cutting machines have gradually become the mainstream equipment. In developed areas such as Australia, CNC cutting machines are phasing out electronic cutting saws. guide. The Chinese market is still using electronic cutting saws to replace manual sliding table saws. Many manufacturers do not understand these two devices. There are more and more customized orders, but they all choose to use electronic cutting saws for processing. In fact, compared with the use of CNC equipment, production efficiency is compromised. In addition, in European and American furniture factories, CNC cutting machines are equipped with automatic loading and unloading equipment. Workers only need to put the plates on the automatic loading and unloading platform. The CNC cutting machine will automatically grab, position, automatically paste barcodes, automatically open materials, and automatically large vertical holes. After the processing is completed, the automatic opening device pushes the plate onto the conveying platform and sucks the vacuum into the conveying belt at the same time. At this time, only one person can pick up the plate during the blanking out, and the processing is completed.

- Fully automatic edge banding machine: divided into straight edge banding machine and curve edge banding machine. The functions can be selected according to different processing requirements, such as pre-milling, tracking, etc. Edge banding machine belongs to traditional woodworking equipment, furniture factory must have edge banding machine.

- Numerical control side hole machine: The application of CNC cutting equipment for panel furniture is becoming more and more popular, and the PTP numerical control drilling machining center for side hole drilling has a small application range due to the high price. The domestically produced PTP CNC drilling iGolden Center has at least more than 250,000, and imported machines have reached more than 600,000. Many customers think that it is not worth the money to simply process side holes. Beginning in 20915, vertical and oblique vertical five-sided drills appeared on the market, with a price of around 200,000. Although a part of the cost was reduced, they did not really gain popularity. The traditional drill row needs to repeatedly adjust the position of the row drill for different sizes of boards. If you find a row drill master, the salary is 6000+. Our company has developed a simple and practical CNC side hole special machine according to the characteristics of the industry. There is no need for a professional driller, so it is loved by the majority of panel furniture factories. People who do not know how to drill can instantly have superb skills in processing side holes, which greatly improves production efficiency and reduces labor costs.

Fourth, the software for dismantling orders, because it is the “brain” of the plate production line, the software directs the operation of automatic equipment, which is indispensable in the production process. With the continuous growth of customer demand, furniture dealers need to show the decorative effect to customers through design software. Furniture companies need front-end design software and back-end output and machine command functions. A good software can accurately guide production, help manufacturers save labor, reduce management costs, optimize production processes, and greatly increase production capacity. At present, the main brands on the market are CabinetVision, IMOS, MV and some domestic software.

The furniture industry, especially furniture manufacturers, should focus on two aspects in the selection of software in the layout of the panel furniture production line: one is the ability to quickly and accurately disassemble the list, and the other is whether the design requires manual intervention. The software can help furniture factories get rid of excessive dependence on personnel, reduce costs in all aspects, bring customized orders into the large-scale production system, and realize the quantity and quality of production. At the same time, considering the future development, the selected software needs to have the ability and experience to interface with automation equipment to prepare for future automated production.

Leave a Reply

You must be logged in to post a comment.