Precision laser cutting machine manufacturers ranking

With the continuous development of my country’s technology and the continuous improvement of industrial processing technology, laser cutting technology is also developing and progressing rapidly. Compare effects.

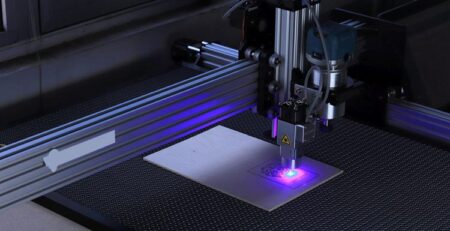

Precision laser cutting machine has high precision, fast cutting speed, small thermal impact, smooth incision, not easy to deform, can cut various shapes and graphics, is not bound by graphics, has stable performance, low maintenance cost and high cost performance.

With the development of modern science and technology, the traditional processing technology of the precision equipment industry has been continuously transformed and upgraded. Whether laser cutting improves processing quality or optimizes product appearance, its competitiveness has gradually become prominent, and its importance has gradually been recognized by manufacturers. It can be concluded that the laser cutting technology of precision laser cutting machines will be more and more widely used in the precision industry, and its development potential and market opportunities are immeasurable.

With the development of modern science and technology, the traditional processing technology of the precision equipment industry has been continuously transformed and upgraded. Whether laser cutting improves processing quality or optimizes product appearance, its competitiveness has gradually become prominent, and its importance has gradually been recognized by manufacturers. It can be concluded that the laser cutting technology of precision laser cutting machines will be more and more widely used in the precision industry, and its development potential and market opportunities are immeasurable.

Precision laser cutting machine manufacturers ranking

The continued success of laser cutting is beyond the reach of most other processes. This trend continues today. In the future, the application prospects of laser cutting will also become more and more broad.

Features of precision laser cutting machine:

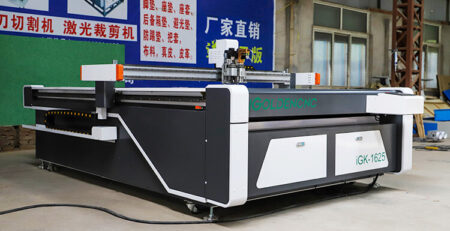

Laser cutting is a relatively advanced processing method used in metal material processing. The F series fiber laser cutting machines produced by Jiabang Laser are equipped with world-renowned brands of fiber lasers, laser cutting heads, linear guides, racks and pinions, servo motors, and CNC systems.

The bed is made of high-strength tailor-welded bed, which is annealed at high temperature and precision machined by a large-scale CNC gantry milling machine, with excellent rigidity, stability and impact resistance.

The beam is made of aerospace standard aviation aluminum and extruded with a 4300-ton press. After aging treatment, the hardness can reach T6, which is the strongest among all aluminum beams. Aviation aluminum has high rigidity, light weight, corrosion resistance, oxidation resistance and low density.

The gas path components are imported components, and the gas path design is advanced and reliable. Three different cutting gases can be installed and can be freely selected. The whole air system adopts high pressure design. When using nitrogen as auxiliary gas to cut metal materials, the nitrogen pressure can reach 3Mpa. In order to ensure the stability of the gas circuit system, imported components are used, which greatly improves the stability of the gas circuit system.

Precision laser cutting machine manufacturers ranking

The principle of laser cutting is to use a focused fiber laser for cutting. Through optical fiber transmission, it has high flexibility, fast speed, few failure points, low maintenance cost, convenient maintenance, high photoelectric conversion rate, and has a great cost-effective advantage in system matching. Mainly used for metal crafts, hardware products, precision machinery. Auto parts, sheet metal processing and other industries.

Note: The cutting thickness of the material depends on the selected laser power.

Popular applications for precision laser cutters include:

> Machinery industry: agricultural machinery, textile machinery, construction machinery, medical equipment, refrigeration equipment, environmental protection equipment and other industries;

> Manufacturing: automobile manufacturing, shipbuilding, elevator manufacturing, chassis cabinets, fitness equipment, mechanical parts

> Advertising industry: decoration engineering, advertising signs, steel structure and other industries;

> Processing industry: sheet metal processing, furniture, kitchen utensils, household appliances, metal handicrafts, hardware tool processing and other industries;

> Precision industry: aerospace, railway locomotives, precision accessories, electronic appliances and other industries.

Leave a Reply

You must be logged in to post a comment.