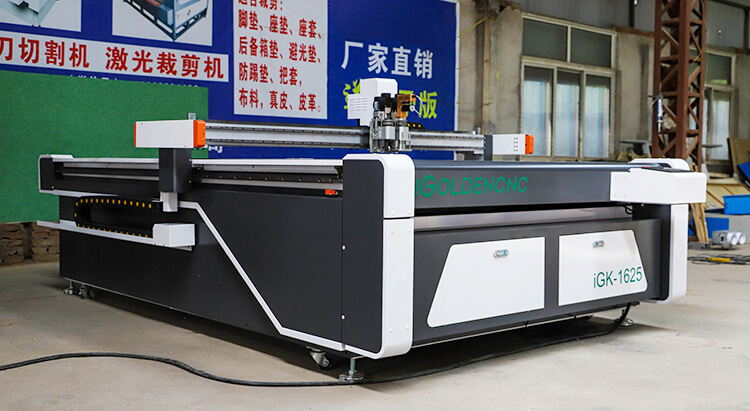

Automatic Rubber Leather Cloth Die Cutting Machine

Automatic Die Cutting Machine are computer-controlled cutting machines that are used in various industries, including automotive, textiles, aerospace, and packaging. The CNC stands for Computer Numerical Control. These machines use a series of cutting and routing tools that are controlled by computer software. Unlike traditional cutting methods, CNC digital knife cutting machines can cut and shape materials into complex shapes with extreme precision.

Automatic Die Cutting Machine

Die Cutting Machine can cut various materials, including foam, rubber, cardboard, leather, and more. The main component of a CNC digital knife cutting machine is the cutting head, which consists of a knife blade that moves up and down while cutting materials. The cutting head automatically adapts to the varying height of the material and can easily cut through multiple layers at once.

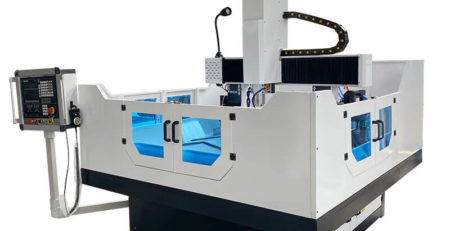

CNC die digital cutting machines deliver precision, speed and versatility for high-volume cutting of even intricate 2D patterns through automated digital tool path technology. Their optimization of die cutting makes them a valuable production asset for sign makers, printers, packaging firms and other cut-to-shape industries.

CNC Die digital knife cutting machines use CAD (Computer-Aided Design) software to create designs. The software is used to program the machine to make intricate cuts and shapes that cannot be achieved using manual methods. The software calculates the most efficient and effective way to cut the material, ensuring that there is minimal waste and maximum accuracy.

The benefits of CNC digital knife cutting machine are numerous. Firstly, they reduce labor and production costs by eliminating the need for manual labor. Secondly, they increase accuracy and speed, which reduces lead times and increases production output. Thirdly, they are capable of intricate cutting, which means that complex shapes and designs are possible.

In a word, CNC digital knife cutting machines are a game-changer in the manufacturing industry. Their ability to cut materials with speed, accuracy, and precision make them vital tools in production lines. These machines ensure efficient and effective manufacturing and reduce the need for manual labor, which leads to lower production costs. As technology continues to improve, CNC digital knife cutting machines will become even more advanced and efficient, further revolutionizing the manufacturing industry.

Advantages of Die Digital Knife Cutting Machines

Have you ever wondered how companies like Nike, Apple, or Tesla are able to produce high-quality and precisely-cut materials for their products? The answer lies in their use of digital knife cutting machines. These advanced machines are designed to cut through materials with extreme precision, speed, and efficiency. But what exactly are the advantages of using digital knife cutting machines over traditional cutting methods?

- Precision Cutting

One of the biggest advantages of digital knife cutting machines is their precision. These machines use highly-advanced technology to ensure that every cut is exact and perfectly aligned. This is especially important when working with intricate designs or patterns, where even the slightest deviation can ruin the final product. With a digital knife cutting machine, you can trust that every cut will be accurate and consistent, time after time.

- Faster Production Time

Another advantage of digital knife cutting machines is their speed. Traditional cutting methods can be time-consuming, especially when working with complex designs or large quantities of materials. With a digital knife cutting machine, however, you can cut through materials in a fraction of the time it takes using traditional methods. This means you can produce more products in less time, increasing your productivity and profitability.

- Reduced Waste

Digital knife cutting machines are also much more efficient than traditional cutting methods when it comes to minimizing waste. These machines use computer-controlled software to optimize the cutting patterns and reduce the amount of material that is wasted. This means you can save money on materials and reduce your impact on the environment by minimizing the amount of waste you produce.

- Versatile in Material Usage

Digital knife cutting machines are highly versatile and can work with a variety of materials, including foam, leather, rubber, fabric, and more. Traditional cutting methods may be limited in the types of materials they can cut, but digital knife cutting machines are designed to handle even the toughest materials with ease. This makes them an ideal choice for companies looking to work with a wide range of materials.

- Increased Quality Control

Finally, digital knife cutting machines offer superior quality control. These machines are able to detect defects in materials and make adjustments to ensure that every cut is precise and of the highest quality. This means that you can produce products that are consistent in quality and appearance, and avoid costly mistakes or defects in your final products.

Die Digital knife cutting machines are a major investment for any company, but their advantages far outweigh the costs. These machines offer a level of precision, efficiency, and quality control that is unmatched by traditional cutting methods. By investing in a digital knife cutting machine, you can increase your productivity, reduce waste, and produce high-quality products that will meet the demands of your customers. So if you are looking to take your business to the next level, consider investing in this cutting-edge technology.

Applications of CNC Digital Knife Cutting Machines

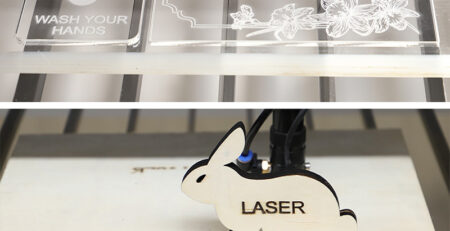

Over the years we have seen the transformation of many industries with the evolution of digital knife cutting machines. In recent years, digital knife cutting machines have become widely popular due to their versatility, speed, and precision. Digital knife cutting machines are the latest development in the following industries, bringing creativity, precision, and speed to manufacturing processes.

- Packaging Industry

The packaging industry is one of the primary beneficiaries of digital knife cutting machines. Packaging design requires intricate precision cutting and creating customized molds for boxes, containers, and cases, which digital knife cutting machines can easily replicate. Digital knife cutting machines help to reduce wastage while accelerating the production process. The machines can cut intricate shapes, curves, and holes while working with different types of materials. The packaging industry can now produce high-quality and cost-effective designs efficiently with digital knife cutting machines.

- Automotive Industry

Automotive manufacturers can use digital knife cutting machines in cutting materials such as foam, leather, and vinyl used in car interiors. These machines are widely used to help reduce waste, cut down on time, and create precise cuts and shapes. Additionally, digital knife cutting machines also significantly reduce the need for human input, thus reducing human error.

- Furniture Industry

The furniture industry can leverage digital knife cutting machines to create cost-effective designs with precision, speed, and enhanced accuracy. Digital knife cutting machines ensure high-quality cutting for different materials, including plastic, metal, and fabric. These machines also help in reducing manufacturing waste and reducing production time. As a result, manufacturers can create durable furniture at an affordable cost.

- Signage and Graphics Industry

Signage and graphics industry players rely on digital knife cutting machines to achieve high precision cuts on vinyl, paper, and rubber materials. Digital knife cutting machines deliver neat cutting paths, enhance finish, and create unique shapes and designs. These machines help in the production of customized signs with quality, speed, and accuracy, ensuring customer satisfaction.

- Apparel and Fashion Industry

The fashion industry relies on digital knife cutting machines to cut fabrics, textiles, and leathers accurately. These machines have reduced the cutting time and efforts required, which has significantly increased the production rates. Digital knife cutting machines provide accurate and intricate cuts, helping fashion designers recreate fabrics in the desired shapes and sizes accurately.

Leave a Reply

You must be logged in to post a comment.