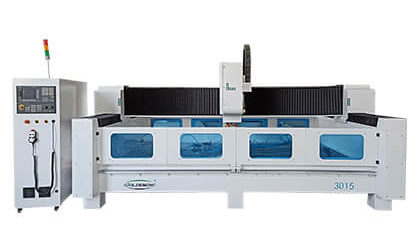

CNC Stone Router-Stone Carving Machine Manufacturers

Which manufacturer produces stone carving machine equipment better? With the rapid development of stone carving machines in the machinery and equipment industry, there are many large, medium and small stone carving machine manufacturers with different product quality and service levels. Therefore, among many manufacturers, the best stone carving machinery manufacturers say which carving machine manufacturer is good, we can comprehensively consider the following aspects:

- bed and rack. The bed is now mainly a steel structure, and the gantry is divided into cast aluminum and square steel structures. The structure and size of the bed and frame directly determine the weight of the machine tool. To a certain extent, the heavier the weight, the better, because the weight represents good stability and directly affects the machining accuracy.

- Spindle and power. The main shaft is divided into water cooling and air cooling according to the working mode. The service life of air cooling is longer than that of water cooling, but the cost is higher

- Adsorption device. Compared with the T-slot table (platen press), mass production can effectively improve efficiency and save clamping time.

- Vacuum cleaner. Dust is especially severe when processing wood materials. If it is too dirty, it is not conducive to the service life of the machine tool or labor. It is recommended to use it

- Drive system. Most woodworking machines are driven by rack-type linear guides. The frame ensures the speed of the equipment (idle distance and processing speed), and the good linearity of the linear guide (square rail) ensures the processing accuracy. The transmission system is particularly important in the entire machine tool, which determines the performance of the machine tool to a certain extent.

- Control method. There are two types: DSP joystick control and computer connection. The handle control makes the operation more convenient, but the service life is shorter than the online type. It only displays the motion coordinates of the equipment, not the processing track, while the computer can fully display the simulated processing track and motion coordinates

- Maintenance. Divided into automatic lubrication system (software control) and semi-automatic lubrication system (manual control).

- Working voltage. Under normal circumstances, the rated voltage is 380V50Hz, and can be changed to 220V50Hz under special circumstances

- Drive system. Compared with the servo system, the stepping system is open-loop control, the torque is small, and the accuracy is poor. Servo system, closed-loop control, large torque, high precision,

- It is divided into control software and programming software. Weihong, Taiwan Baoyuan, Syntec and other control software are relatively mature. Programming software: domestic Wentai, Jingdiao, etc.; foreign: French type3, UK: ArtCAM, etc.

- After choosing the corresponding configuration, it is time to compare the prices, i.e. price/performance ratio

- After-sales service. Good after-sales service is particularly important, which can be inspected from the aspects of brand, region, and whether the manufacturer has production training strength.

Which stone engraving machine manufacturer is the best? Choose iGolden CNC, a dedicated technical service team, tailor-made for you, create efficient application solutions, and a dedicated manufacturing team to provide you with fast speed, high precision, and long-term use. Stable and reliable engraving machine equipment!

Leave a Reply

You must be logged in to post a comment.