What are the equipment of custom furniture automation production line?

Furniture production equipment has a variety of different functions, realizing the intelligence and automation of furniture production. This production method not only saves labor costs, but also improves processing efficiency and product quality. Therefore, furniture production equipment is increasingly favored by furniture manufacturers.

Why choose furniture production equipment?

Why choose furniture production equipment?

We all know that traditional furniture production machines are usually counted and disassembled by woodworkers, dismantled, push table saws, cutting, rowing, drilling and edge sealing machines to test, assemble and package.

This production method has disadvantages such as high labor cost and low production efficiency. Therefore, the traditional processing methods are not enough to meet people’s processing requirements. Instead, furniture production equipment, which can have many different options, is becoming more and more popular. The production cost and processing effect of different production lines are different. The choice of furniture production equipment depends on your own production conditions.

Furniture production equipment: CNC engraving machine

So far, CNC engraving machine is one of the most widely used furniture manufacturing equipment in the world. Furniture production lines use CNCs to manage their functions. The use of CNC technology also increases the productivity, precision and efficiency of furniture machinery. Therefore, it provides higher precision than conventional tools. Almost every furniture maker should own a CNC engraving machine.

CNC engraving machines with different settings can perform various furniture manufacturing processes. Such as cutting, carving, drilling, etc. Here I would like to introduce a CNC engraving machine suitable for engraving complex 3D patterns or cylindrical furniture parts.

Four-axis CNC engraving machine

As the name suggests, a 4-axis CNC engraving machine can process 4 axes. Generally speaking, there are two types of furniture making machines. One is a real four-axis CNC engraving machine, whose main shaft can rotate 180 degrees left and right. Thus, the wood can be carved in all directions, and the sides of the planks can be grooved or drilled. Therefore, wooden furniture machines can create three-dimensional patterns. The other is a CNC machine with a rotating device. It is very convenient to engrave on cylindrical furniture. Such as table and chair legs, armrests, studs, studs, etc.

Therefore, the four-axis CNC engraving machine has a wide range of applications in the manufacture of traditional or complex style furniture.

Like CNC engraving machines, CNC cutting machines are also one of the most widely used furniture manufacturing machines in the industry. CNC cutting machine is the most suitable cutting machine for manufacturing panel furniture and custom furniture. But unlike the CNC engraving machine, the CNC cutting machine can carry out long-term cutting operations. Many furniture factories use CNC cutting machines to cut and perforate cabinet products. Such as kitchen cabinets, cabinets, cabinets, shelves, etc.

The main difference between CNC engraving machine and CNC cutting machine is that CNC engraving machine is mainly used to engrave patterns on furniture panels, but it is not suitable for a large number of cutting work. The CNC cutting machine is mainly used for cutting board furniture, which can be cut for a long time.

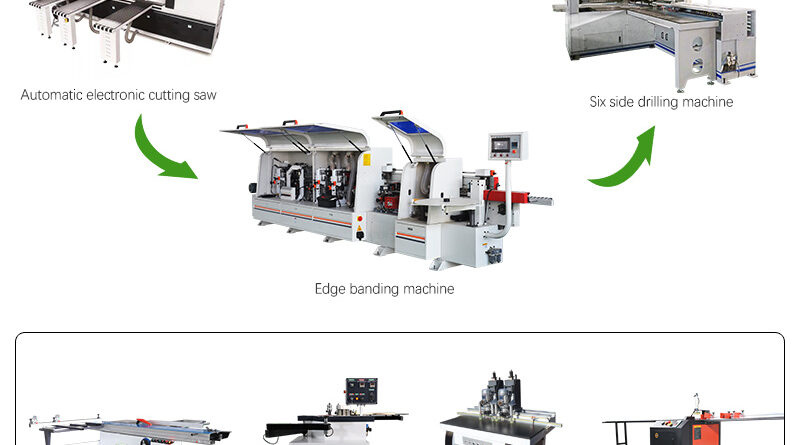

The standard furniture production line mainly includes a four-process CNC cutting machine, an automatic edge banding machine, a six-sided drilling machine, and whether it is equipped with auxiliary equipment such as five-drilling machines. It can be used for the custom production of door panels, processing more than 75 pieces every 8 hours (standard size: 2.44*1.22 meters).

Four-process CNC cutting machine: used for cutting and unloading. Automatic labeling is recommended for accurate labeling. After supporting professional panel furniture design software, the bar code can be printed in advance for automatic labeling and cutting. The tool does not need to be turned over.

Automatic edge banding machine: Automatic edge banding is used for straight edge banding after sheet cutting. It is recommended to choose the edge banding tape with analysis tracking, moderate automation and good processing effect. If it is used for edge banding of special-shaped plates, it is recommended to choose arc edge banding for processing.

Six-sided drilling machine: This drilling machine is used for drilling and milling grooves on each side of the edge banding area, with high precision, high speed, and one-time positioning processing.

Auxiliary equipment: mainly used for panel saws, auxiliary air compressors, etc., for floor processing.

How to choose a furniture production line?

With the rise of panel furniture, more and more custom furniture needs to be processed, so custom panel furniture factories increasingly require mass production and automation. Panel furniture production lines have become an urgent need for large furniture manufacturers. So how to choose the right panel furniture production line?

First of all, choose a reasonable panel furniture production line according to the factory plan. If the company has only a few workers in the factory, mainly processing customization, and the number of customers is small, it is recommended to choose a complete panel furniture production line, which mainly meets the production of panel furniture.

Secondly, according to the company’s customer volume, choose a reasonable panel furniture production line plan. If the company has been operating for a long time and the panel furniture market has a stable source of customers, if you order more custom furniture every day, you need to choose a panel furniture production line with high power and complete craftsmanship.

Leave a Reply

You must be logged in to post a comment.